CMMS Implementation Steps 101

TABLE OF CONTENTS

- Steps in the CMMS Software Implementation Process

- Planning and Strategy

- Data Organization and Migration

- CMMS Configuration and Testing

- Onboarding and Training

- Installation and Go-live

- Monitoring and continuous improvement

- PLANNING AND STRATEGY

- 1. Setting Goals and Objectives

- 2. Establishing Management Commitment and Building Cross-Functional Alignment

- 3. Committing to ROI and a Realistic Budget

- 4. Determining Implementation Scope

- 5. CMMS Vendor Selection

- 6. Managing Change

- DATA ORGANIZATION AND MIGRATION

- 7. Data Organization

- 8. Data Migration and Entry

- CMMS CONFIGURATION AND TESTING

- 9. CMMS Configuration

- 10. Testing

- ONBOARDING AND TRAINING

- 11. Onboarding and Training

- CMMS INSTALLATION

- 12. Install and Go-live

- MONITORING AND CONTINUOUS IMPROVEMENT

- 13. Reporting and Analysis

- 14. Continuous Improvement

- Expect Challenges

CMMS Software Implementation - Success Statistics

Depending on the source, CMMS vendors acknowledge the failure rate for CMMS implementations is 50%, and can be as high as 80%. At first glance, these statistics are shocking but not surprising when it’s examined further. In 2020, a report titled “The Cost of Poor Software Quality in the US (CPSQ)” released by The Consortium for Information and Software Quality™ (CISQ™), presented similar findings for the overall CMMS software industry. CISQ™ which is co-founded by OMG and the Software Engineering Institute at Carnegie Mellon University, is an industry leadership group that develops international standards for software quality. The CISQ™ CPSQ report showed 19% of projects are canceled before they get completed, and 47% are challenged for reasons such as being over budget, being behind schedule, and producing low-quality deliverables. This translates into a failure rate of 66%, amounting to a cost of $260 billion in 2020 compared to $177.5 billion in 2018. The economics of this pose a serious concern.

The problems don't end even when the CMMS implementation is considered a success. Consider the following:

- Only 6% of companies claim to use 100% of their CMMS functions

- 61% of maintenance managers find implementing CMMS challenging

- 39% use CMMS consistently to track maintenance tasks

- 10% of work orders are not updated

As these statistics demonstrate, the reasons for poor implementation and adoption likely come down to the following: ownership issues, system misconfiguration, poor training, resistance to change, and poor communication. In order to avoid high CMMS failure rates, it’s important to begin by reviewing the various steps in a general software implementation process.

Steps in the CMMS Software Implementation Process

Depending on the document you refer to, the most important phases of software implementation are as follows.

CMMS Implementation Project Plan - Strategy

- Setting goals and objectives

- Establishing management commitment and building cross-functional alignment

- Establishing ROI and a realistic budget

- Determining implementation scope

- Selecting CMMS vendor

- Managing change and CMMS implementation risks

Data Organization and Migration

This step recognizes the problems associated with legacy data and suggests steps to restore data integrity. It is then followed by data migration and a fool-proof system for data entry on an initial and continuous basis.

CMMS Configuration and Testing

This step emphasizes the appropriate method of configuring the CMMS system, and how testing can help in catching possible errors that might creep into production.

Onboarding and Training

This step looks at some pragmatic steps needed to execute onboarding and training to maximize CMMS adoption.

Installation and Go-live

In this step, there are a series of actual steps that need to be taken in order to go live with the system. Organizations that are early in their digital journey can explore options for a progressive launch starting with a single department.

Monitoring and continuous improvement

This last step focuses on how reports and a culture of continuous improvement can help a CMMS implementation compound the gains that it can reasonably achieve over time.

These steps are broken down further as follows:

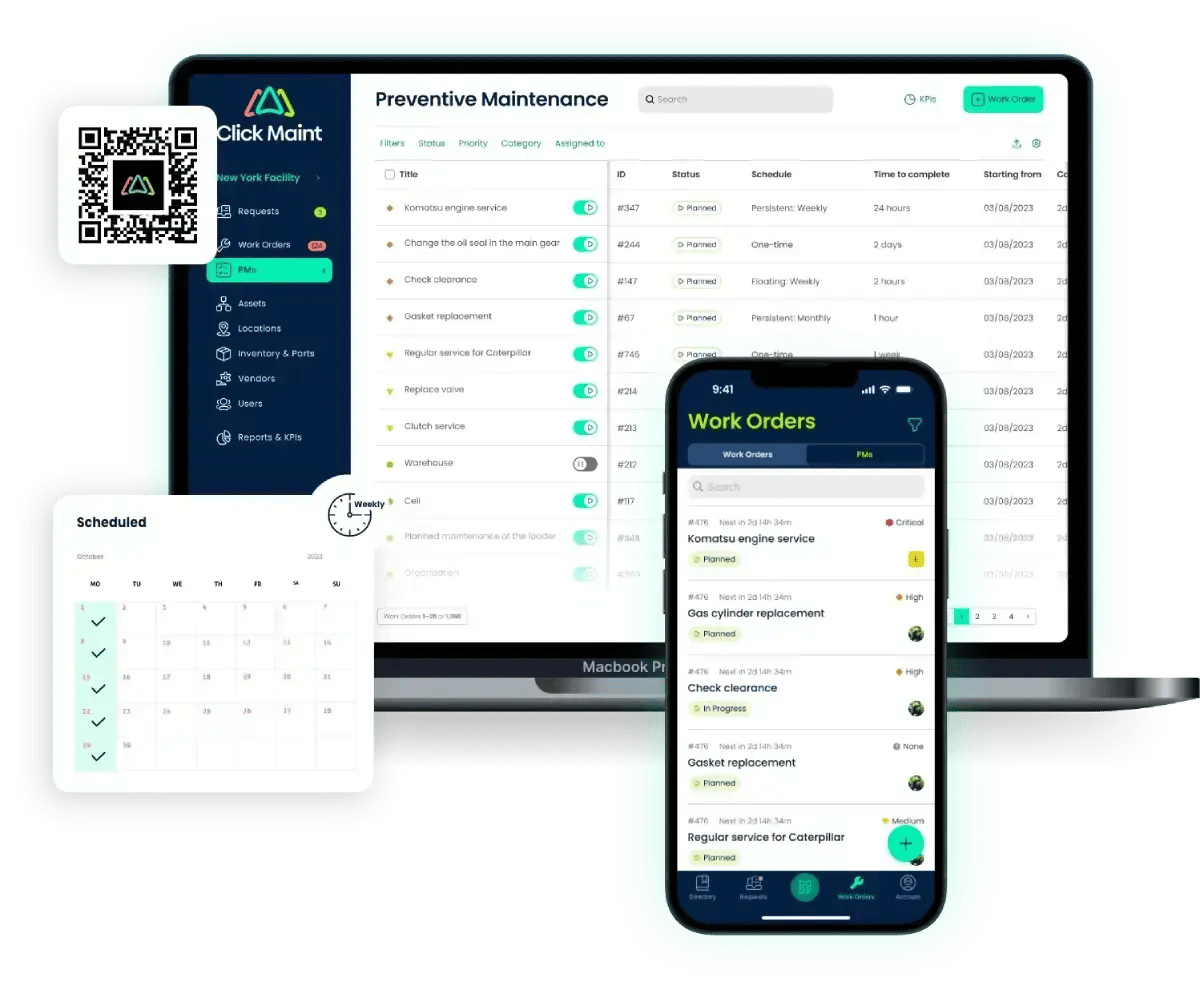

See how affordable Click Maint CMMS is

STRATEGIZE THE CMMS IMPLEMENTATION PLAN

1. Setting Goals and Objectives

The first step in implementing a CMMS is to identify your goals and objectives. What do you want to achieve with your CMMS? Do you want to reduce downtime? Improve asset reliability? Increase productivity? Is there a strategic digital transformation initiative with which the CMMS implementation has to align? Once you have identified your goals, you can tailor your CMMS implementation plan to achieve those goals.

This step should not be done hastily. It is best to take the time needed to establish maximum alignment among team members. This will increase the odds of success of the CMMS implementation plan. This step also offers an opportunity to be as specific as possible about key milestones, roles and responsibilities, codes table, parts numbering system, etc. Detailed planning at this stage will reduce confusion later on.

2. Establishing Management Commitment and Building Cross-Functional Alignment

The CISQ™ CPSQ report unequivocally identified top management encouragement as a critical success factor for software projects including implementation. In CMMS implementations, executive management need to be educated on it, unless it is part of an organization-wide digital transformation project. Management should be apprised not only of the initial acquisition costs but also of the ongoing costs associated with maintenance, training, upgrades, and contingencies. Transparency with regard to total project costs will encourage management commitment to see the project through successfully. Management’s role isn’t about getting involved with paperwork, meetings, and approvals. Instead, it’s about leading from the top. When leadership is on board, there’s a greater chance that employees will follow.

A CMMS implementation will affect many departments including production, planning, purchasing, operations, and IT. A cross-functional approach to CMMS implementation will help build alignment early in the project. These departments can suggest which activities need improvement in the context of a CMMS. In so doing, agreeable objectives can be set for the departments and the overall project.

3. Committing to ROI and a Realistic Budget

A focus on return on investment or ROI forms the cornerstone of a CMMS implementation. During the planning phase, a clear case for ROI must be presented and balanced with a realistic budget. The tangible benefits of a CMMS need to be spelled out. Attention should be paid to cost escalations. If ignored, they can depreciate enthusiasm and goodwill. Underestimating the budget may result in having to later deal with unaccounted for escalating costs. To be considered, are costs associated with customizing the CMMS and integrating it with existing software. Implementing a CMMS along with its ongoing maintenance comes with real costs. All these costs need to be considered during the early stages of CMMS implementation. It’s essential that all of these costs are factored into the total cost of ownership (TCO). This will prepare the organization well for continued investment into the implementation’s success.

4. Determining the CMMS Set up Scope

Determining the scope of a CMMS will set the tone for implementation. The more effort directed determining its scope will reduce difficulties during CMMS implementation. The scoping step considers the following:

- Needs assessment

- Features list - What modules are need-to-have and which are nice to have? Which modules can be implemented later?

- List of integrations (present and future) required

- List tasks and corresponding owners

- Risk management and mitigation with a focus on technology obsolescence

5. CMMS Software Vendor Selection

Choosing the wrong CMMS system is a major reason for implementation failure. To avoid making the wrong choice, the decision to select a CMMS should be done carefully. Choosing the right CMMS software is critical to the success of your implementation. Look for a software solution that meets all of your requirements and is easy to use. Consider factors such as vendor reliability, scalability of functionalities, customization options, access control features, mobile functionality, top CMMS software ratings, and reporting capabilities.

The following are questions that will be helpful when selecting the right CMMS vendor.

- What is the digital maturity of your organization?

- Will the CMMS be used as an organization-wide digital transformation initiative or just the maintenance department’s CMMS implementation project?

- Is it a point CMMS implementation i.e. just a work order, or will it be a comprehensive CMMS implementation covering asset management to inventory management?

Additionally, consider the following as part of your vendor checklist

- Proven body of work with demonstrated ability to scale,

- Financially sound,

- Is critical functionality supported in-house?

- Reference checks with known users.

6. Managing Change

One of the most common challenges organizations face when implementing a new system is resistance from employees who are not comfortable with change. This is a sensitive but critical step to get buy-in from all team members and users. Change management is a critical line item in most CMMS implementations. It should never be assumed that just because the company has chosen a CMMS, that all employees are aware of it or understand its purpose. Some members may be hesitant because they may view it as a tool that might make them redundant and put their jobs at risk. On the other hand, others might be excited about the prospect of learning something new in their career. It is essential to communicate clearly why the new system will be beneficial and provide adequate training to ensure successful adoption.

Recognizing that not all team members will welcome a CMMS, is an important first step in change management. Consider the following steps as helpful ways to introduce a CMMS and in doing so, it may establish a more receptive environment for its implementation. Teams could also consider cmms implemenation services.

- Sending information from the CEO or Department Head via a text message or an email explaining the project.

- Placing communication posters covering top concerns and benefits

- Conducting sessions to address employees’ questions and concerns

- Identifying Champions and Detractors

- Assigning roles and responsibilities

- Soliciting volunteers for project management tasks

Experience Click Maint CMMS now

30-Day Free Trial

No Credit Card needed.

Instant access to all features & modules with an optional live walk-through with a Click Maint expert

Book a live Demo

In this 30-minute demo, see firsthand how our easy CMMS can streamline your operations, enhance productivity, and reduce downtime.

DATA ORGANIZATION AND MIGRATION

7. Data Organization

It is not uncommon for businesses to store disorganized data, in different forms and in different locations. Data is integral to a CMMS. Before a system can be implemented, it is important to ensure all data to be entered is cleaned. This means that it should be free of errors and duplications, and it must be complete. The data cleaning process will ensure that the implementation will have an accurate starting point.

Data cleansing isn’t the only challenge. Data gathering is also a factor. Implementations face overruns because data-gathering may be incomplete. Gathering data takes time because project team members still need to attend to their operational responsibilities. Deciding which data needs to be gathered is an important decision to be made in providing the necessary focus to the project. The following are key data points to consider when setting up a CMMS database:

- Equipment manufacturer PM schedules with or without modifications,

- Equipment model, costs, warranty, and identification number,

- Assets including buildings and fixtures,

- Machine and parts numbering convention,

- IT teams involvement.

This step is critical when proposing a realistic “go live” date. Implementation teams are advised to be conservative when estimating timelines for this step. Collecting all the required information, cleaning it, and delivering it in a usable format could take several months, depending on the size of the organization, the number of assets, its production volume, the condition of the data, and the scope of the system’s application.

8. Data Migration and Entry

Data migration is a crucial part of any successful CMMS implementation. Plans need to be made about how the data will be migrated to the new system from either an existing system , spreadsheets or physical data sheets. Identify what data needs to be migrated, how it will be mapped between systems, and who will be responsible for ensuring data integrity. The data migration should be simulated in a test environment before execution.

After data migration, comes data entry. It has two components.

- One-time data-entry exercise that takes substantial time and focus. This is best done through contractors and/or temporary hires to avoid any biases creeping in from existing team members.

- Ongoing data entry during operations in order to keep tasks running. At this stage, assign responsibilities for data entry. Decide who will enter information related to work orders and preventive maintenance schedules. The project team is encouraged to consider the pros and cons of using managers and technicians, assistants, or a combination of these.

CMMS CONFIGURATION AND TESTING

9. CMMS Configuration

After selecting your software solution and planning the data strategy, it’s time to configure the system according to your unique operational needs. This will include but are not be limited to the following setups:

- Equipment hierarchies,

- preventive maintenance schedules,

- work order types,

- priority levels,

- notification preferences,

- user roles/access rights,

- IT security

10. Testing

It is essential to always test the CMMS system thoroughly before it is launched. To do so, create test scenarios covering all aspects of maintenance management processes and their related workflows. Involve end-users in user acceptance testing (UATs) to ensure that everything is working as expected. Once testing is complete, it’s advisable to launch the system in phases so that users can get used to it gradually.

ONBOARDING AND TRAINING

11. Onboarding and Training

The importance of onboarding and training cannot be overstated. A proactive communication and promotion plan highlighted previously is viewed as priming stakeholders including end-users for an upcoming CMMS introduction. This should be followed up with proper training at two levels:

- Initially, at the time of getting started

- Periodic training continuously at a defined frequency

While many CMMS systems are designed to be intuitive, it should not be assumed that the users will use it on their own effectively or efficiently. CMMS is a sophisticated piece of software. It will require formal training with hands-on exercises for maintenance technicians, supervisors, and administrators who will be using the system daily. The CMMS training program should consider the following:

- CMMS use exercises specific to your operations

- Clear definition of terms

- Timing of the training to cater to new team members that join the company

- Training enough master users and student users so that users can also be a resource to each other rather than just depending on the next training session

- Identify internal champions for guidance and troubleshooting questions

- Annual training calendar

- Creating a culture of continuous learning on the CMMS

- Creating process manuals, SOPs, and an internal wiki for asynchronous reference

A powerful CMMS training program is an organization’s best bet to extract maximum value from the CMMS implementation.

CMMS SET UP

12. Install and Go-live

Once you have tested your CMMS and made the necessary adjustments, it’s time to go live! Plan a rollout strategy that minimizes operational disruptions while ensuring all users are aware of the new changes.The following is suggested:

- Create new accounts and logins

- Launch the CMMS integration with other internal systems

- Email a “Getting Started” notification to the users

- Provide onboarding, training materials, and internal wiki to end-users

To reduce launch-related anxiety among end users, the implementation should be actively managed. When necessary, project managers should address technical issues, turnover, and employee resistance, in a timely manner.

A progressive CMMS implementation offers more control. For large organizations, CMMS implementation can begin with just one department. For some organizations, the CMMS may be launched starting with a department that holds maximum potential while for others, it may be a department that has heavier maintenance problems. Rolling out the CMMS progressively, keeps the project more manageable.

MONITORING AND CONTINUOUS IMPROVEMENT

13. Reporting and Analysis

After going live with a new CMMS, it’s important to monitor its usage and effectiveness regularly. Track key performance indicators (KPIs) such as work order completion rates or equipment downtime to identify areas for improvement. It is recommended that these KPIs are discussed and decided in advance during the planning phase. This will ensure cross-functional alignment in the tracking numbers that matter. In the initial stages, the focus should be on the quality of the reports rather than the number of reports. The following tips will come in helpful:

- Report frequency

- Automate reporting dashboards preferably via email

- Determine the recipients of the reports

- Determine actionable information being put into execution

- Establish feedback loops for reports improvement

- Assess ease of customization for granular reporting

14. Continuous Improvement

The CMMS is designed to grow with the organization. Continuous improvement should be an ongoing process and can be achieved through regular reviews of data gathered from the system.

- User Feedback: Collect feedback (active and passive) to identify FAQs and update the documentation

- CMMS Support: Chat support, in-app tooltips, and knowledge bases will help users with on-demand support. This, in turn, will help project managers to address problem areas with the CMMS.

- CMMS Audit: This will be helpful in identifying problems as well as training gaps for existing and new users.

Developing a culture of continuous improvement is usually easier said than done. Persistent efforts will yield results. Repeated communication to end users about how the CMMS can deliver an edge in the competitive marketplace will reinforce its value and encourage ongoing use. It is important to also stress that their participation improves the CMMS and because of this, it reduces downtime, enhances workplace safety, and improves customer satisfaction.

Expect Challenges

A successful CMMS implementation can help streamline maintenance processes, reduce downtime, and improve asset lifespan. However, implementing a CMMS can be complex and challenging without a proper plan in place. CMMS implementation can be a daunting task, but with proper planning, execution, and management, it can bring significant benefits in terms of cost savings, improved productivity, and increased efficiency. Understanding your organization’s specific needs, developing a detailed implementation plan, choosing the right vendor, and providing sufficient training are key factors for ensuring successful implementation and ongoing use.