CMMS Software Trends: For 2024 & Beyond

Computerized Maintenance Management Systems (CMMS) are not new for most enterprises.

A CMMS software centralizes maintenance data and facilitates maintenance activities within an organization. This simplifies the maintenance management processes and helps automate the process by collecting and storing maintenance information in a single location. It helps ease the process of analyzing data and tracking the health and performance of assets within an organization.

Compared to the past when many businesses manually tracked equipment and inventory, CMMS systems have demonstrated that they improve maintenance operations for businesses and are now widely adopted in almost every industry. As technologies evolve, we are seeing significant shifts in the maintenance management software space. This article explores trends we expect to see take off with CMMS software this year.

Let's get started with the 7 CMMS Software Trends to Watch out for in 2024. (Here is the updated cmms software trends for 2026)

The implementation of CMMS technology has brought about a significant improvement in maintenance processes, resulting in increased reliability, efficiency, and reduced downtime. With the shift to mobile access over the past few years, efficiency and productivity gains have only increased. The demand for CMMS software is increasing and users are driving product innovation, pushing providers to invest in product development and find even better ways to drive efficiencies through their maintenance software.

1. Increasing Focus on Predictive Maintenance

One of the biggest CMMS software trends is the use of predictive maintenance to help organizations take preemptive steps to schedule maintenance and minimize instances of equipment breakdown and downtime. This proactive approach uses Internet of Things (IoT) sensors to get real-time data collection while leveraging Big Data or AI-based models to analyze the information and predict chances of failure before they happen. As a result, leveraging predictive maintenance through IoT technologies, maintenance operations can avoid downtime which slows production, and costly reactive repairs.

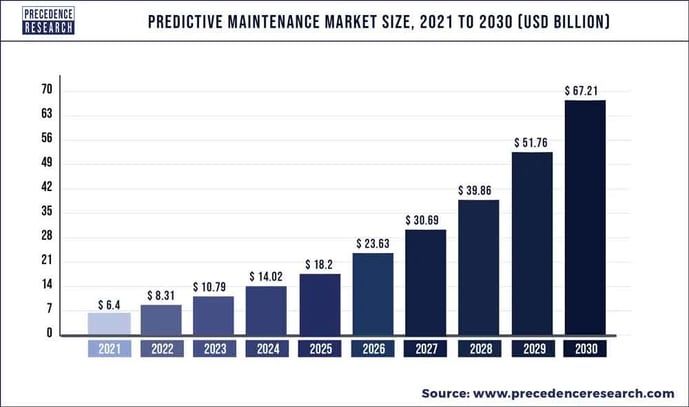

A report by Precedence Research shows the predictive maintenance market size was USD 8.31 billion in 2022, and is projected to exceed USD 67.21 billion by 2030, having a whopping CAGR growth of 29.86%.

2. Internet 4.0, IoT, & AI

With advanced digitization, smart devices, Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) becoming more mainstream for business, these technologies are helping companies get real-time data on asset and maintenance processes performance. This data is instrumental in helping companies adjust processes, make more informed decisions, cut costs, and invest dollars where they should.

By employing Internet (or Industry) 4.0, companies are leaning more on digital technologies, where it makes sense and using their human capital where IoT and AI aren’t suitable. IoT sensors collect real-time data and trigger automated workflows to ensure equipment is performing optimally and AI-powered CMMS is now being used to provide businesses with predictive outcomes.

3. Intelligent Data-Driven Maintenance

Similar to the previous CMMS software trends, the use of advanced technologies such as Internet 4.0, IoT, and AI can help organizations shift from traditional maintenance processes that were based on scheduled events to more predictive or intelligent data-driven maintenance.

This allows the maintenance teams to take proactive steps and implement logical data-driven maintenance alternatives. Some use case examples are streamlining certifications, understanding the root cause for failures, conducting better audits, and leveraging the power of real-time data to future-proof and augment maintenance processes.

4. Advanced Analytics Capabilities

As data-collection methods evolve, it becomes increasingly important to possess advanced analytical capabilities to make specific business decisions.

In 2024, the CMMS industry is expected to witness a surge in AI-based technology and tools, enabling organizations to derive greater value from their data. By leveraging this information, businesses can streamline their maintenance processes, improve forecasting accuracy, and make informed decisions regarding equipment, maintenance, and other operations.

5. Rise in Mobile-ready Solutions

Most enterprise CMMS applications started with desktop-based software. But as technology evolves, mobility is a crucial requirement for maintenance operations. With technicians having to move around, CMMS tools must be mobile-friendly and allow access to information on multiple devices and platforms.

With mobile-friendly apps that use login and authentication mechanisms, maintenance teams can access the information via their mobile devices, which in turn, helps communication, cuts time and improves operational efficiency.

6. Adoption of Cloud-based Systems

In line with the previous trend, organizations prefer cloud-based CMMS systems over traditional on-premise systems. This is not only due to the convenience and flexibility that cloud-based systems offer but also has to do with the advanced security mechanisms which allow authentication for login and access controls. Cloud hosting has seen tremendous improvements where security and compliance are concerned. CMMS providers are taking steps to demonstrate the lengths they go to, to ensure client data is secure by obtaining certifications (SOC2, ISO 27001, etc.) Additionally, client-hosted CMMS tends to be expensive, given the on-site hardware and IT infrastructure, whereas cloud-based CMMS is scalable and cost-effective. With the improvements that have been made with cloud-based security, IT executives are no longer leaning toward on-premise. Higher costs, maintenance requirements, expensive updates are some of the reasons for going cloud.

7. High Demand for Integration with Other Business Applications

In the past, CMMS software was seen as a tool that only benefited maintenance departments. The benefits were short sighted and were seen primarily as a tool to track preventive maintenance and spare parts. Today, however, businesses see how a CMMS fits into the organizational strategy as a whole. Thus, integration feature is key to most CMMS Software implementaions. It’s clear that if production machines or key assets are not available, production is slow, or customer service is interrupted. This ultimately impacts the businesses ability to compete and deliver value to its customers.

Now that CMMS software is recognized as a critical tool for meeting corporate objectives, there is a high demand for integrating it with other key business applications. Many organizations are integrating their CMMS with their Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), Human Resource Information System (HRIS) and other tools. In 2024, CMMS users are demanding integration capabilities with other business applications, and CMMS providers are delivering.

To conclude, the future of CMMS software is exciting and full of unique opportunities. The industry is evolving to include advanced technologies, and these trends are already transforming the maintenance management landscape in more ways than one. As a result, the overall CMMS market is expected to grow significantly with a respectable CAGR of 8.2% from 2023 to 2030, according to Grand View Research.

The rise in CMMS system usage can be attributed to their effectiveness, dependability, and relative ease of integrating with cutting-edge technologies that are quickly becoming the new business-standard. These tools are transforming the ways companies manage their maintenance operations through automating processes, better decision making and more precise and predictable insights. As a result, 2024 is poised to see some fast and exciting changes.

TABLE OF CONTENTS

Keep Reading

School facilities are busy, high-traffic places. On average, 45.8 million students attend ...

10 Feb 2026

There is also no shortage of acronyms in the maintenance world. So, here is one more to add ...

6 Feb 2026

You may be wondering: if you are already using CMMS software in your organization, aren’t ...

5 Feb 2026

Although artificial intelligence (AI) has been around since the mid-1950s, it wasn’t until ...

3 Feb 2026

Fire safety is often treated as a compliance checkbox rather than an ongoing operational ...

30 Jan 2026

Schools are regarded as places of learning where children are exposed to the basics of ...

29 Jan 2026

Facility maintenance, much like running a business, defies one-size-fits-all solutions. The ...

27 Jan 2026

When we think of inspections, we usually think about ensuring regulatory compliance and ...

23 Jan 2026

In maintenance operations, having the right spare parts in the right amount and at the right ...

22 Jan 2026

The relentless march of technology continuously reshapes the industry landscape, and with it, ...

20 Jan 2026

New Year’s resolutions tend to focus on lifestyle or financial changes, often aimed at making ...

16 Jan 2026

Now that 2026 has arrived, we’ll see that manufacturing trends will matter more than ever, as ...

15 Jan 2026

Now that 2026 is here, it’s a great time to assess what can be achieved in maintenance ...

13 Jan 2026

2026 is when the role of a CMMS Software in capital allocation comes to the fore. This is the ...

12 Jan 2026

Choosing the right work order software is no longer optional for maintenance teams in 2026. ...

6 Jan 2026

By 2026, CMMS platforms will no longer be the limiting factor in maintenance performance. ...

30 Dec 2025

Spare parts management within maintenance can make the difference between a problem-free ...

16 Dec 2025

Every maintenance team eventually faces the same question: When should we repair, and when ...

12 Dec 2025

Enterprise Asset Management (EAM) software has become a cornerstone for organizations aiming ...

12 Dec 2025

Unexpected equipment breakdowns can disrupt operations, increase repair costs, and reduce ...

11 Dec 2025