CMMS Software growth - Why More Businesses are Implementing CMMS

CMMS Software growing

What is it about Computerized Maintenance Management Software systems (CMMS) that makes it so attractive to a wide range of businesses across a variety of sectors? After all, before they were first introduced in the late 1960’s, companies seemed to manage quite well using standard pen and paper. As with almost everything, circumstances have changed as they continue to do so. Companies today are challenged by increasing competition, tight operations margins, economic demands and technological innovations. Traditional maintenance management strategies that did the job before aren't as effective or efficient as they once were.

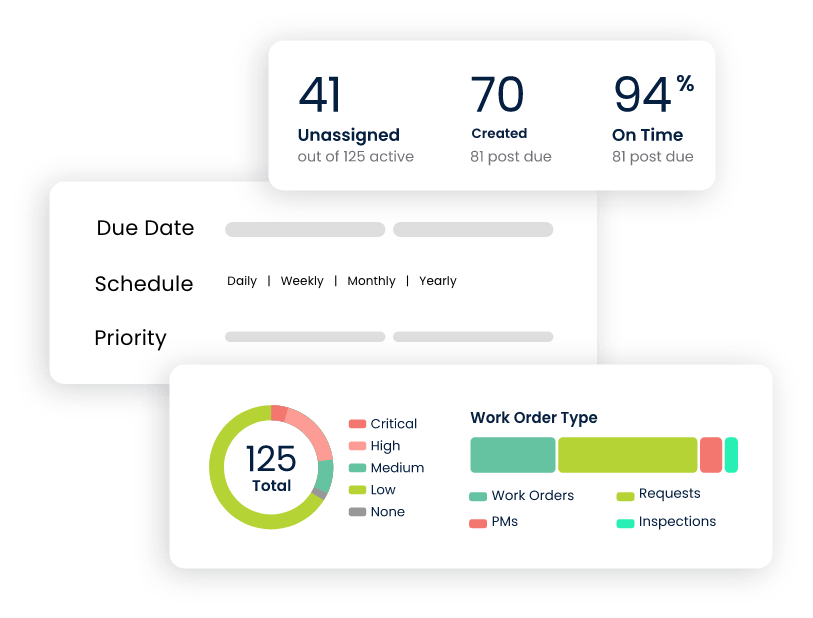

To begin, CMMS software is used to manage and streamline all maintenance operations. Overall, CMMS software helps organizations efficiently manage their equipment, materias, labor and expenses and maintenance tasks, leading to increased productivity, reduced downtime, and better resource utilization. Not too long ago, CMMSs mainly catered to manufacturing operations. But today, we see the CMMS marketplace offers a wide variety of systems and options that are able to meet the needs of businesses of all types and sizes no matter what industry.

As organizations are recognizing the importance of efficient maintenance management to reduce downtime, extend asset life, and improve overall productivity, they are increasingly turning to CMMSs for their maintenance management solutions. Today, CMMS software is a burgeoning market. In 2022, the global CMMS market size was valued at USD 1.06 billion. It is also expected to grow at a compound annual growth rate (CAGR) of 10.9% for the next seven years.

Factors Associated with CMMS Popularity

The following are some of the reasons for CMMS’s growing popularity among a wide range of businesses:

1. Improved Maintenance Efficiency

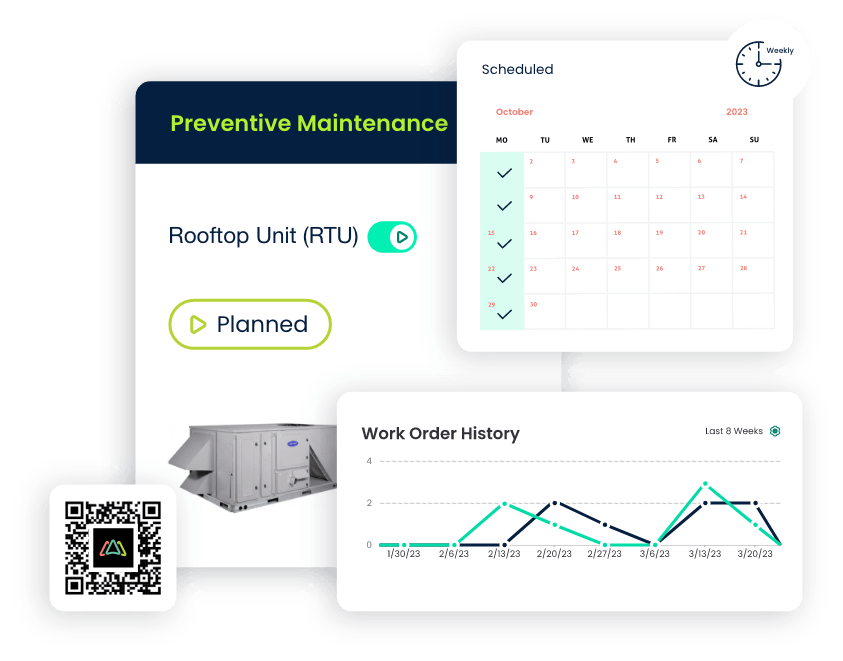

CMMS software has the ability to streamline maintenance processes, making it easier to manage work orders, track assets, and schedule preventive maintenance. In particular, a CMMS’s work order management function enables businesses to create, manage, and track work orders efficiently. It streamlines the workflow, assigns tasks to the appropriate personnel, sets priorities, and keeps all stakeholders informed about the progress of maintenance activities.The overall result is increased operational efficiency and reduced downtime, as maintenance tasks are managed more effectively.

2. Cost Savings Using Preventive Maintenance Management

By implementing CMMS software, businesses are able to optimize their maintenance operations using a preventive management approach. By using a routine scheduled approach to maintenance management, the benefit is a reduction in equipment downtime and failure. In the past, companies utilized a reactive maintenance approach, when equipment issues were attended to only when problems arose. A CMMS’s proactive approach to maintenance helps prevent costly breakdowns and extends the lifespan of assets, ultimately saving money in the long run.

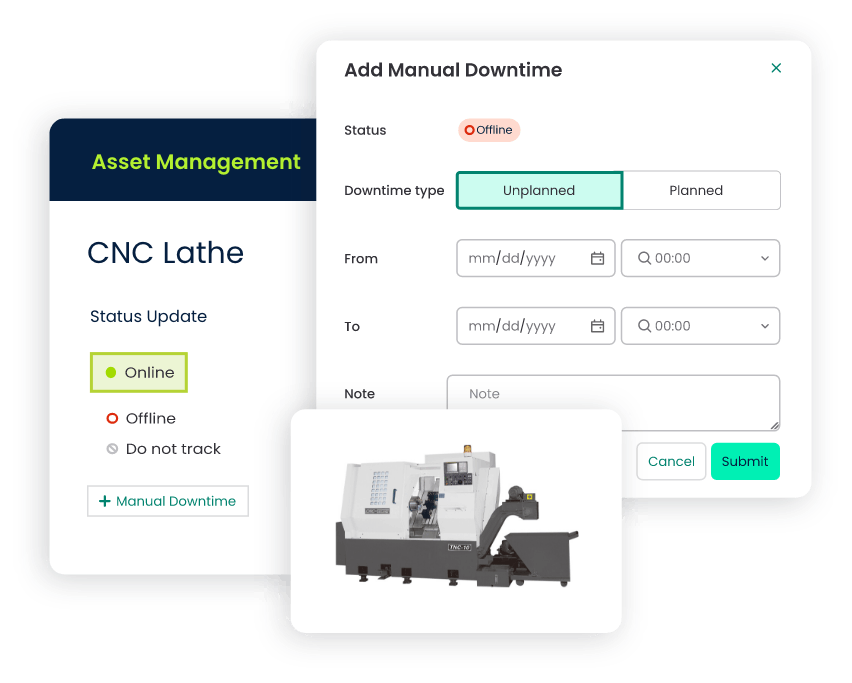

3. Enhanced Asset Management

CMMS software makes it possible for businesses to keep track of their assets, including maintenance history, warranty information, and spare parts in inventory. Having this information in a report format enables better decision-making regarding asset replacement or repair.

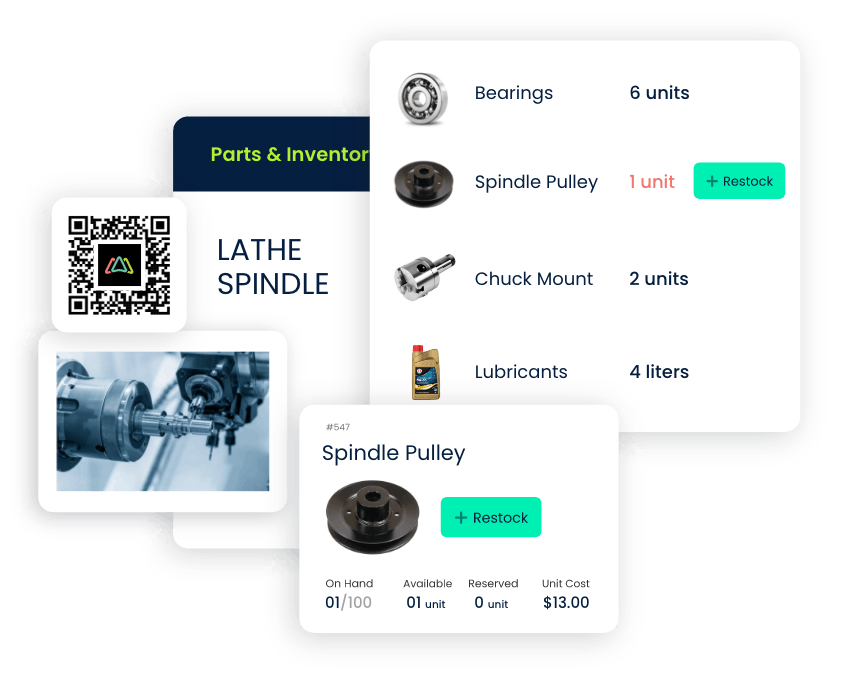

4. Inventory Control

CMMS systems often include inventory management capabilities, allowing businesses to keep track of spare parts, materials, supplies, and inventory cost. This feature helps avoid stockouts and overstocks, optimizes inventory levels, and ensures that technicians have the necessary resources readily available.

5. Regulatory Compliance

When organizations are subject to specific regulations and standards, CMMS software assists in maintaining compliance tasks by keeping detailed maintenance records, generating reports for audits, and scheduling inspections as required according to industry regulatory standards.

6. Data-Driven Insights

CMMS software reporting capabilities generate valuable data and insights related to maintenance activities, asset performance, and historical trends. Company owners and maintenance managers are then able to identify patterns, optimize maintenance schedules, analyze equipment performance and make informed decisions about asset management.

7. Remote Access and Mobility

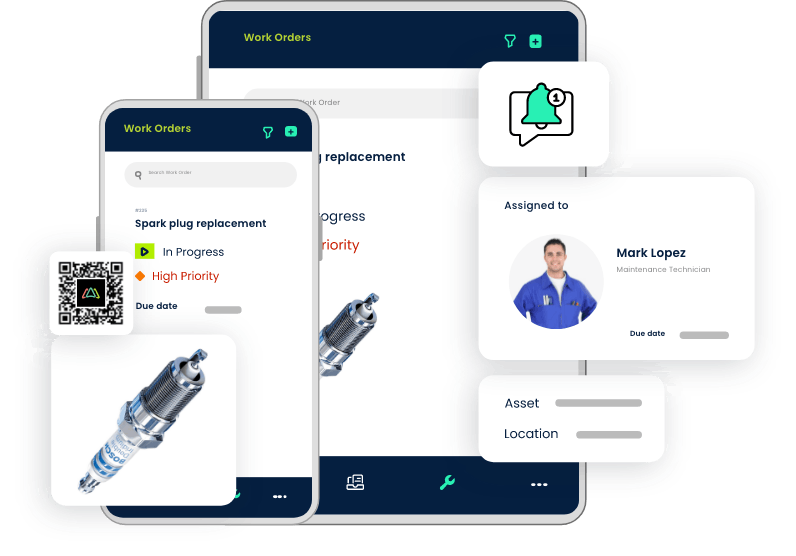

Today’s cloud-based CMMS solutions enable remote access to maintenance data, allowing maintenance teams to access information and submit work orders from anywhere, improving collaboration and responsiveness. Previously, work orders that at times took hours to days to process, can now be initiated in minutes.

The wide adoption of smartphones and tablets have made mobile maintenance and work order management the norm. With Work Order Apps, users are notified of assigned work and requests in real-time and these can be updated in seconds, on-site while completely eliminating any paper trail. Mobile CMMS makes it easy to remotely create and update work orders, add images, scan QR codes and more.

8. Integration and Compatibility with IoT

loT is an acronym for the Internet of Things. In the maintenance management world, this relates to equipment with sensors that are able to send real time operations data from it to a CMMS. It can also integrate other business software such as Enterprise Resource Planning (ERP). This relatively new capability is a valuable tool in predictive maintenance which identifies issues before they cause significant problems. CMMS integration enhances data flow, facilitates automated processes, and provides a comprehensive view of maintenance operations.

9. User-Friendly Interfaces

Since not everyone is computer savvy, more recently developed CMMS solutions come with user-friendly interfaces, making it easier for maintenance teams to adopt and feel confident when using the software effectively.

10. Scalability

Given the previously noted challenges that companies face, CMMS software is able to accommodate the growing and changing needs of both small businesses and larger enterprises without having to purchase another system. As well, CMMS providers have been tailoring their offerings to meet the specific needs of different industries. Where CMMS software was primarily targeted to larger enterprises in the past, today’s CMMS are priced and offer functionality that is suited for SMB and enterprise businesses. This customization has attracted more customers seeking specialized maintenance solutions for their particular sectors. The scalability and industry-specific Solutions of CMMS makes it a versatile solution across industries.

11. Customer Satisfaction

Without a doubt, efficient maintenance processes lead to better functioning assets and equipment, resulting in improved product or service quality. This strengthens customer satisfaction and loyalty.

12. Sustainability Initiatives

Apart from optimizing the lifespan of assets, environmental considerations are also becoming an increasing concern. CMMS software can help businesses implement sustainability initiatives by optimizing maintenance practices, and reducing waste as well as potentially toxic emissions while prolonging the life of assets.

13. Competitive Advantage

CMMS takes the time and guesswork out of conducting efficient and effective maintenance management tasks. Businesses that adopt CMMS software gain a competitive edge by reducing downtime, saving costs, and improving overall operational efficiency compared to their competitors who might still rely on traditional maintenance methods.

Business Sectors Using CMMS

If you’re still unsure if your business can benefit from CMMS software, the following is a list of business sectors that have embraced its capabilities in their maintenance operations:

1. Manufacturing Companies

Manufacturing plants were the first to make the shift from traditional maintenance management approaches to CMMS. Having a wide range of equipment and machinery requiring regular maintenance and monitoring made CMMS software an attractive solution. CMMS helps manufacturers schedule preventive maintenance, track spare parts inventory, and reduce unplanned downtime. (cmms software for manufacturing)

2. Facilities Management Companies

Businesses that specialize in commercial facilities maintenance, such as office buildings, hospitals, universities, and shopping malls, use CMMS to manage maintenance tasks for various systems like HVAC, elevators, lighting, plumbing, and more. The efficiency and time saving benefits are two of the reasons these companies choose CMMS as their preferred maintenance management solution.

3. Energy and Utilities

Power plants, water treatment facilities, and other utilities often use CMMS to keep their critical infrastructure running efficiently, ensuring reliable energy production and distribution. Since so many people rely on these essential systems, CMMS makes consistent and reliable delivery of its services possible.

4. Transportation and Logistics

Transportation companies with fleets of vehicles, airlines, and shipping logistics firms use CMMS to manage maintenance for their vehicles and transportation assets. CMMS can prevent and reduce unnecessary delays due to malfunctions in any of these assets.

5. Healthcare Institutions

Hospitals and healthcare facilities rely on Healthcare CMMS to ensure the smooth operation of medical equipment and facilities, adhering to strict compliance and safety standards.

6. Hospitality Industry

Hotels and resorts utilize CMMS to manage maintenance for guest rooms, HVAC systems, elevators, and other amenities. Having well functioning facilities is a key factor in customer satisfaction and loyalty.

Download the Preventive Maintenance Checklist for your HVAC System

Image: HVAC Systems

7. Municipalities and Government Agencies

Local governments and public entities use CMMS to manage maintenance for public infrastructure like roads, bridges, water supply, and sewage systems. CMMS’s ability to scale and integrate with this large network of organizations makes it a valuable resource.

8. Food and Beverage Industry

Restaurants, food processing plants, and breweries employ CMMS to manage maintenance for production equipment and keep their facilities compliant with hygiene and safety regulations. CMMS can accommodate maintenance management tasks for single operations all the way up to large facilities and country wide chain food and beverage organizations.

9. Oil and Gas

Companies in the oil and gas industry adopt CMMS to ensure the efficient maintenance of drilling rigs, pipelines, and refineries, reducing downtime and increasing safety. Just like companies in the manufacturing industry sector, oil and gas facilities have many pieces of sophisticated equipment of various kinds that benefit from the sophisticated and robust CMMS features and capabilities.

10. Educational Institutions

Schools, colleges, and universities use CMMS to manage maintenance for their buildings, classrooms, and equipment. CMMS can be scaled to the needs of small colleges, universities as well as entire school districts.

11. Data Centers

Data centers rely on CMMS to manage the maintenance and uptime of their critical infrastructure, including servers, cooling systems, and power supply. The sensitivity of data center equipment makes the ongoing maintenance capabilities of CMMS an excellent choice.

Conclusion

Businesses of all sizes and across numerous sectors are increasingly choosing to implement CMMS software to optimize maintenance processes, reduce costs, improve asset management, enhance data-driven decision-making, and gain a competitive advantage in their respective industries. Given these capabilities, the previously noted projected growth trend for CMMS is sure to be realized.

When considering a CMMS, it’s important to note that its features and requirements may vary depending on the size, complexity, and unique needs of each business. With many options available in the CMMS marketplace, it is essential that you begin with conducting a thorough evaluation and then choosing a solution with the CMMS features that best fit your organization’s specific needs and requirements.

TABLE OF CONTENTS

Keep Reading

Whether it’s football, baseball, hockey, or basketball, sporting events are big business. To ...

13 Feb 2026

The energy industry is facing numerous challenges on several fronts, including the transition ...

12 Feb 2026

School facilities are busy, high-traffic places. On average, 45.8 million students attend ...

10 Feb 2026

There is also no shortage of acronyms in the maintenance world. So, here is one more to add ...

6 Feb 2026

You may be wondering: if you are already using CMMS software in your organization, aren’t ...

5 Feb 2026

Although artificial intelligence (AI) has been around since the mid-1950s, it wasn’t until ...

3 Feb 2026

Fire safety is often treated as a compliance checkbox rather than an ongoing operational ...

30 Jan 2026

Schools are regarded as places of learning where children are exposed to the basics of ...

29 Jan 2026

Facility maintenance, much like running a business, defies one-size-fits-all solutions. The ...

27 Jan 2026

When we think of inspections, we usually think about ensuring regulatory compliance and ...

23 Jan 2026

In maintenance operations, having the right spare parts in the right amount and at the right ...

22 Jan 2026

The relentless march of technology continuously reshapes the industry landscape, and with it, ...

20 Jan 2026

New Year’s resolutions tend to focus on lifestyle or financial changes, often aimed at making ...

16 Jan 2026

Now that 2026 has arrived, we’ll see that manufacturing trends will matter more than ever, as ...

15 Jan 2026

Now that 2026 is here, it’s a great time to assess what can be achieved in maintenance ...

13 Jan 2026

2026 is when the role of a CMMS Software in capital allocation comes to the fore. This is the ...

12 Jan 2026

Choosing the right work order software is no longer optional for maintenance teams in 2026. ...

6 Jan 2026

By 2026, CMMS platforms will no longer be the limiting factor in maintenance performance. ...

30 Dec 2025

Spare parts management within maintenance can make the difference between a problem-free ...

16 Dec 2025

Every maintenance team eventually faces the same question: When should we repair, and when ...

12 Dec 2025