Asset identification

The first step is to identify all the assets that need to be maintained or repaired. These assets can include equipment, facilities, vehicles, or any other physical assets.

MadgeTech

Starsky

NECC

The Pacific Club

Steer Medical

Lake Elsinore Strom

Grupo Herroro

The Oswego Hotel

MPI Label Systems

Strom Chasers

US Sport Planes

CMOA

Classical Academy

Turnstone

KFC

Orchard

Taco Bell

Jersey Mike’s

PROFESSIONAL PLAN

$ 42 USD

PER USER PER MONTH

$ 35 USD

PER USER PER MONTH

Driving Excellence with Maintenance Management

IMPROVE maintenance operations with centralized asset information and workflow visibility.

AUTOMATE manual tasks to save time, reduce errors and improve productivity.

ATTAIN consistency through knowledge transfer and cloud-based documentation of maintenance procedures.

MAKE informed maintenance decisions and increase equipment reliability.

REDUCE maintenance costs through preventive maintenance and timely repairs.

SIMPLIFY compliance audits by generating responses and reports tailored to an audit’s demands.

IMPROVE productivity by reducing equipment breakdowns and maintenance-related delays.

STREAMLINE maintenance processes and optimize material and resource distribution.

No Credit Card needed.

Instant access to all features & modules with an optional live walk-through with a Click Maint expert

In this 30-minute demo, see firsthand how our easy CMMS can streamline your operations, enhance productivity, and reduce downtime.

Designed for Seamless Operations and Unparalleled Performance!

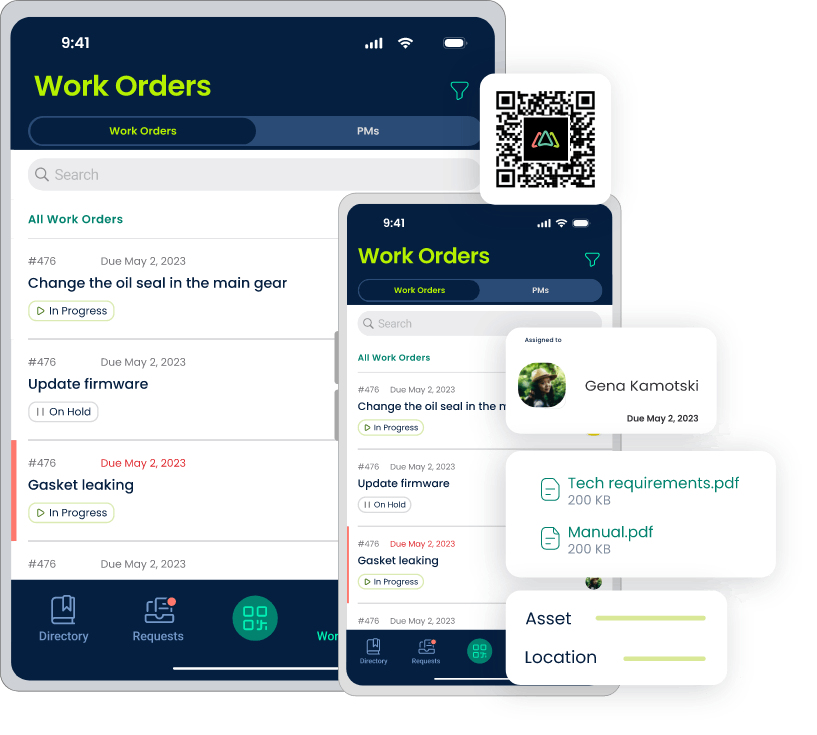

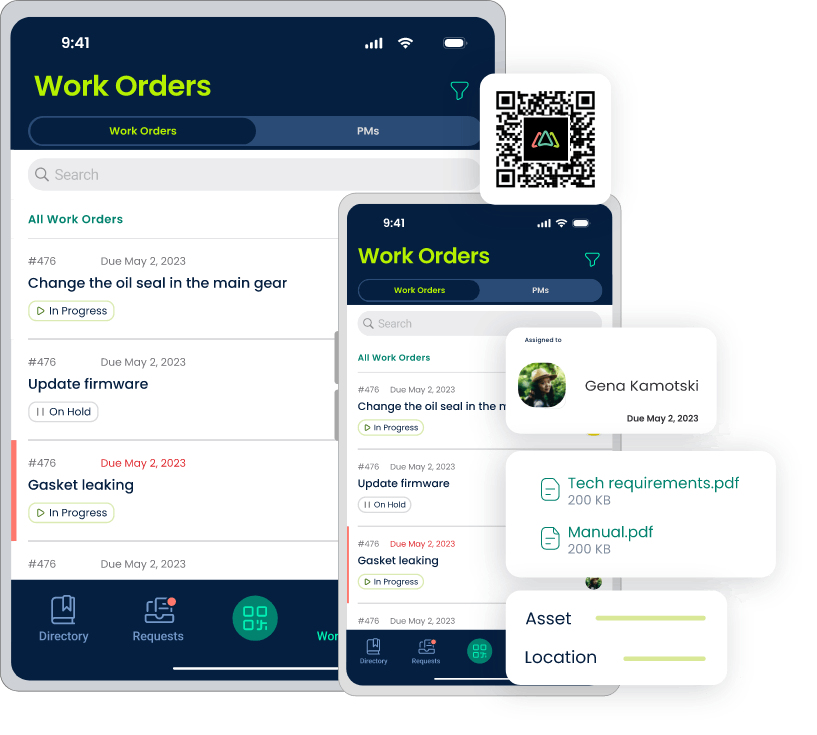

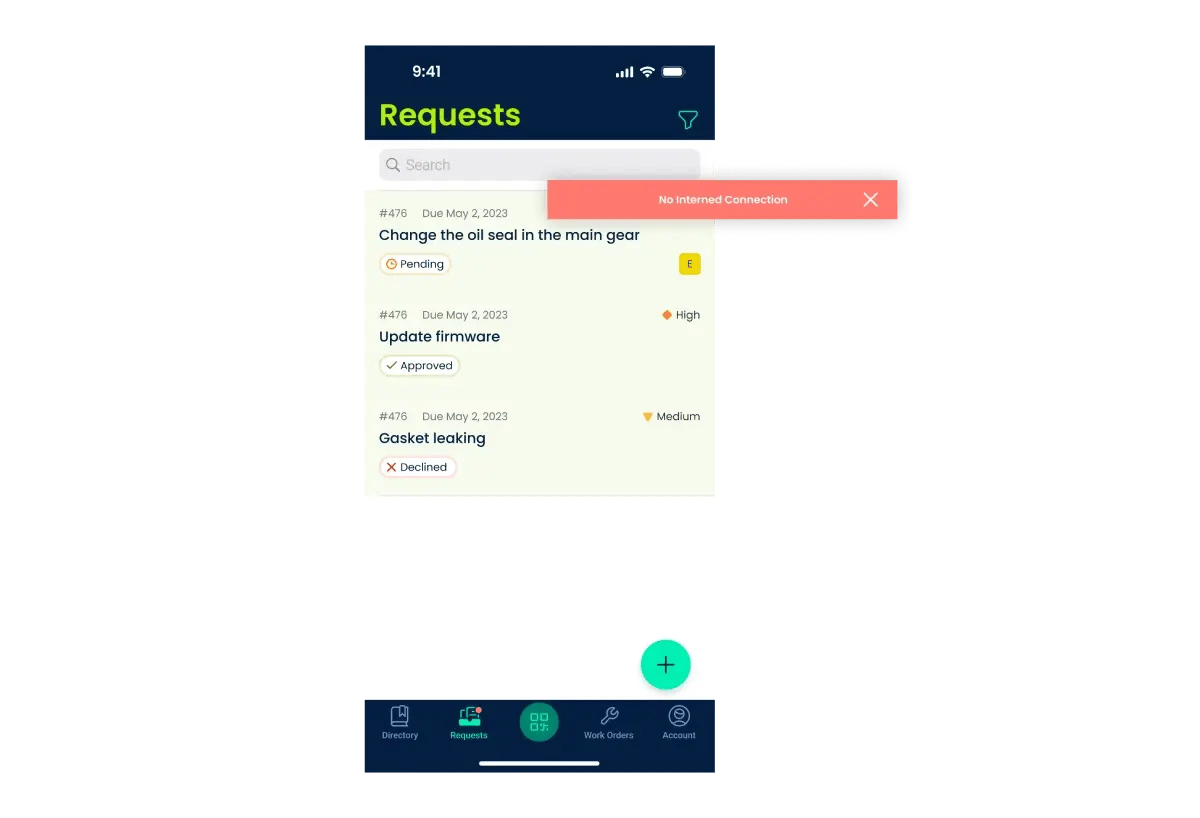

For Maintenance Management on-the-go

Access the CMMS from anywhere, using mobile devices such as smartphones or tablets.

Scan barcodes on assets, parts, and inventory using a mobile device's camera.

Use voice commands to perform tasks, such as creating work orders or updating asset information.

Receive real-time updates on work order status, asset history, and inventory levels.

Communicate and collaborate with team members and external partners, such as contractors or suppliers.

Receive alerts and notifications for upcoming maintenance tasks, low inventory levels, or other important events.

Attach images and videos to work orders and asset records, providing additional context for technicians and managers.

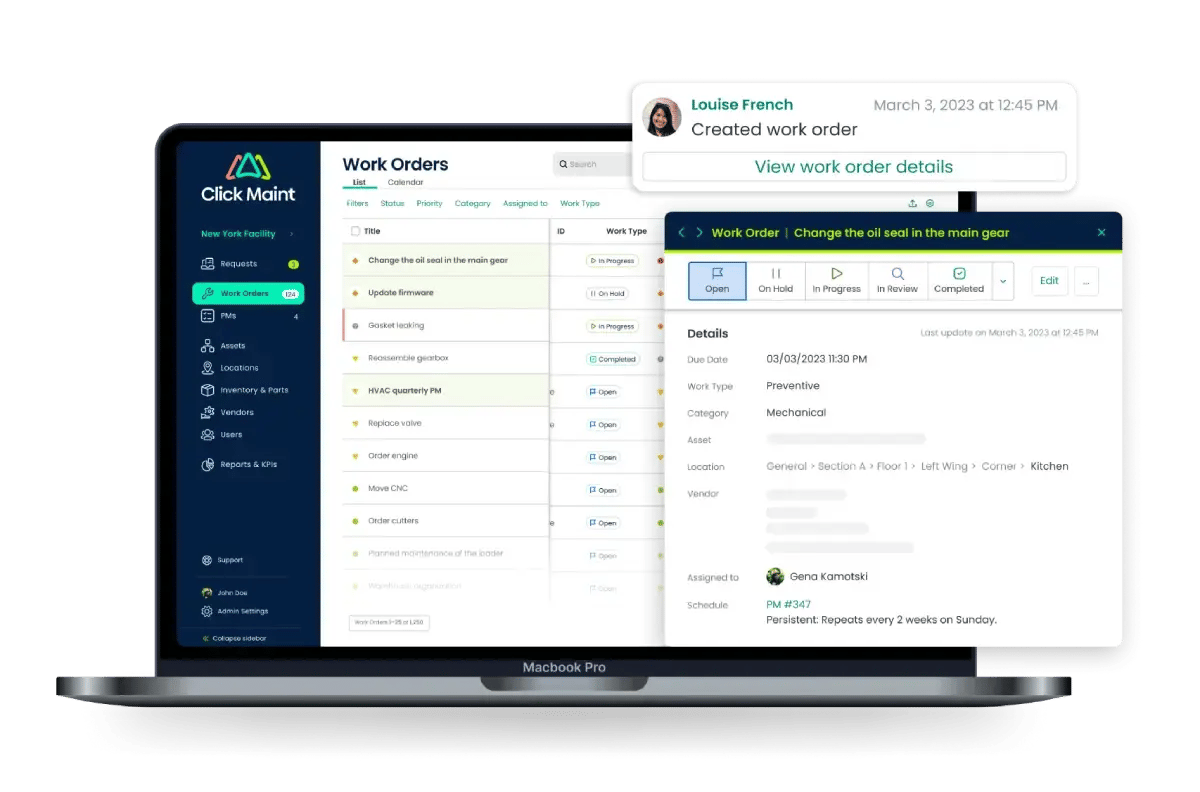

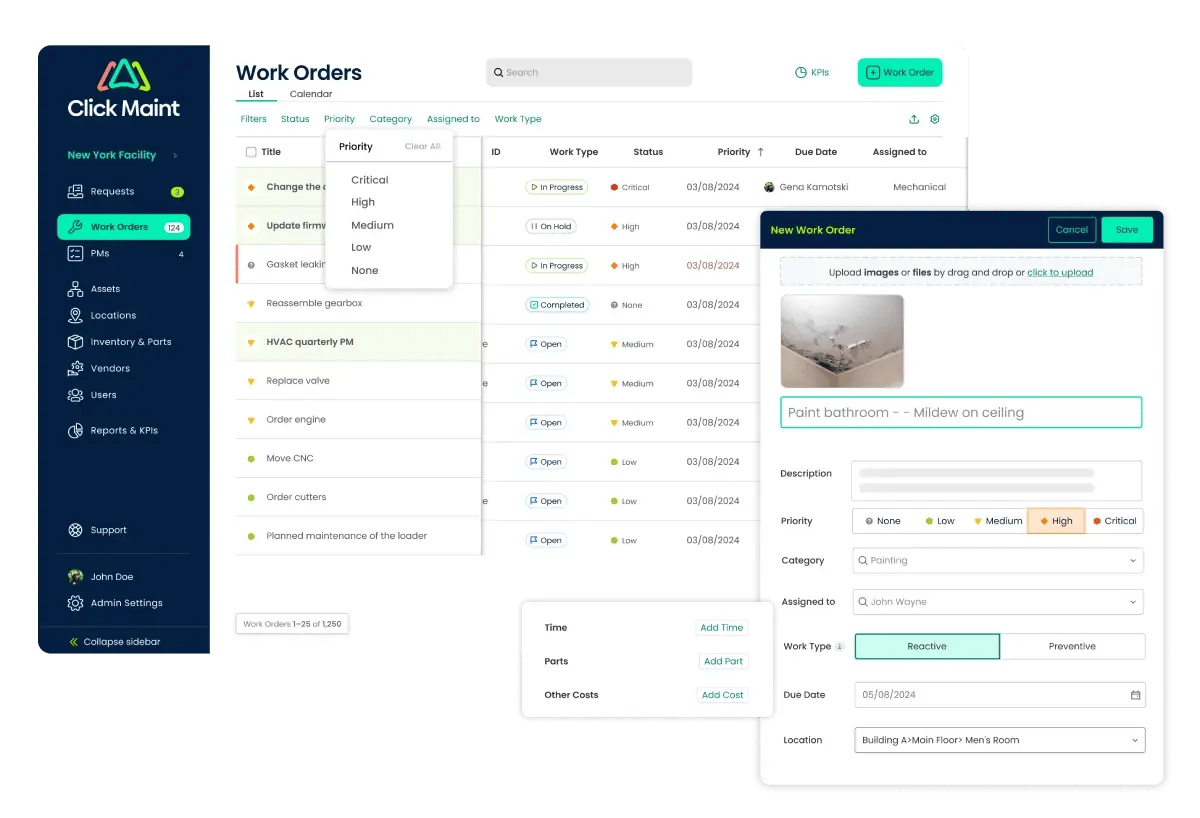

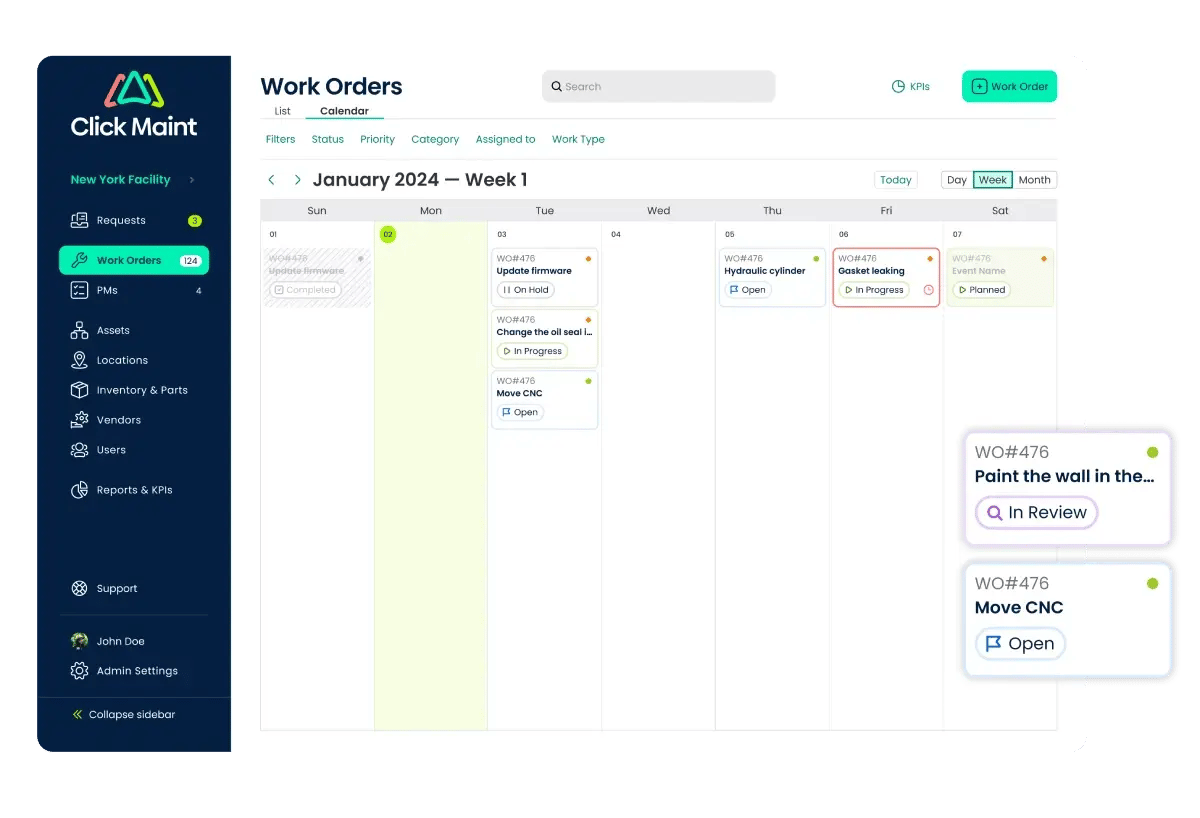

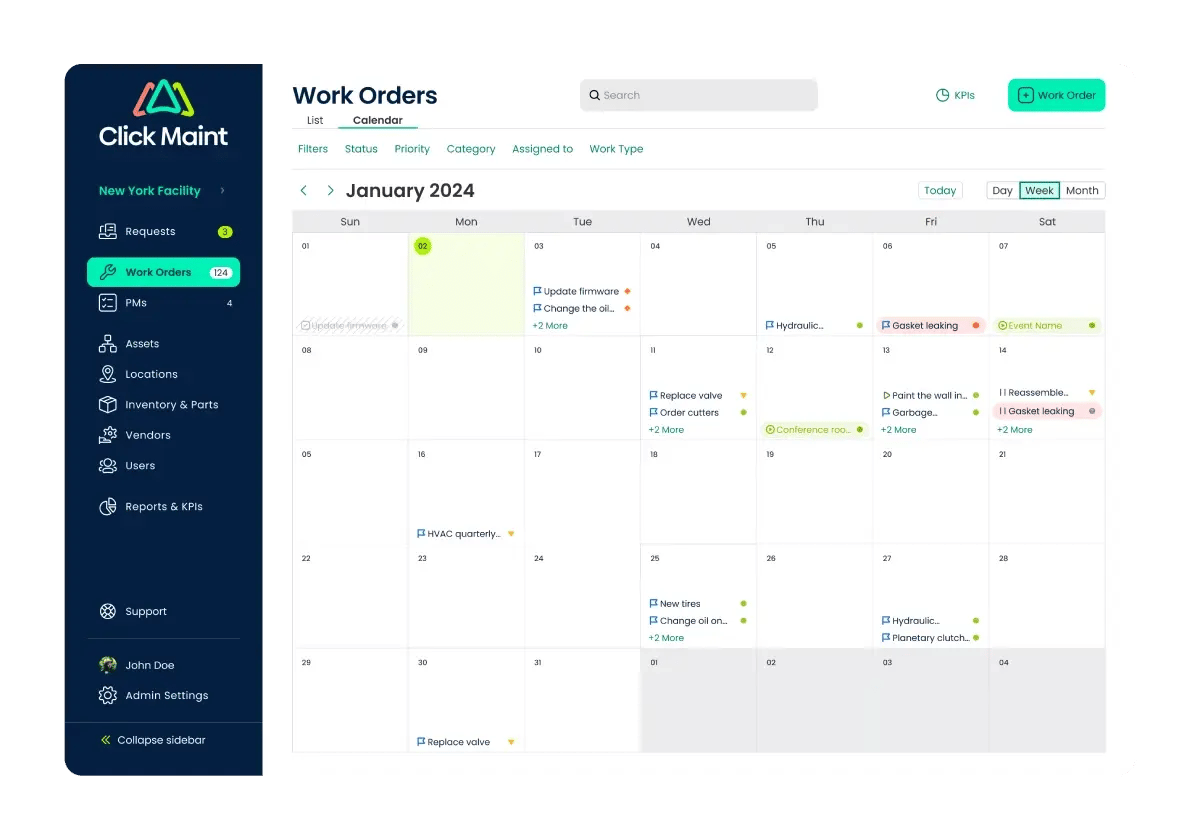

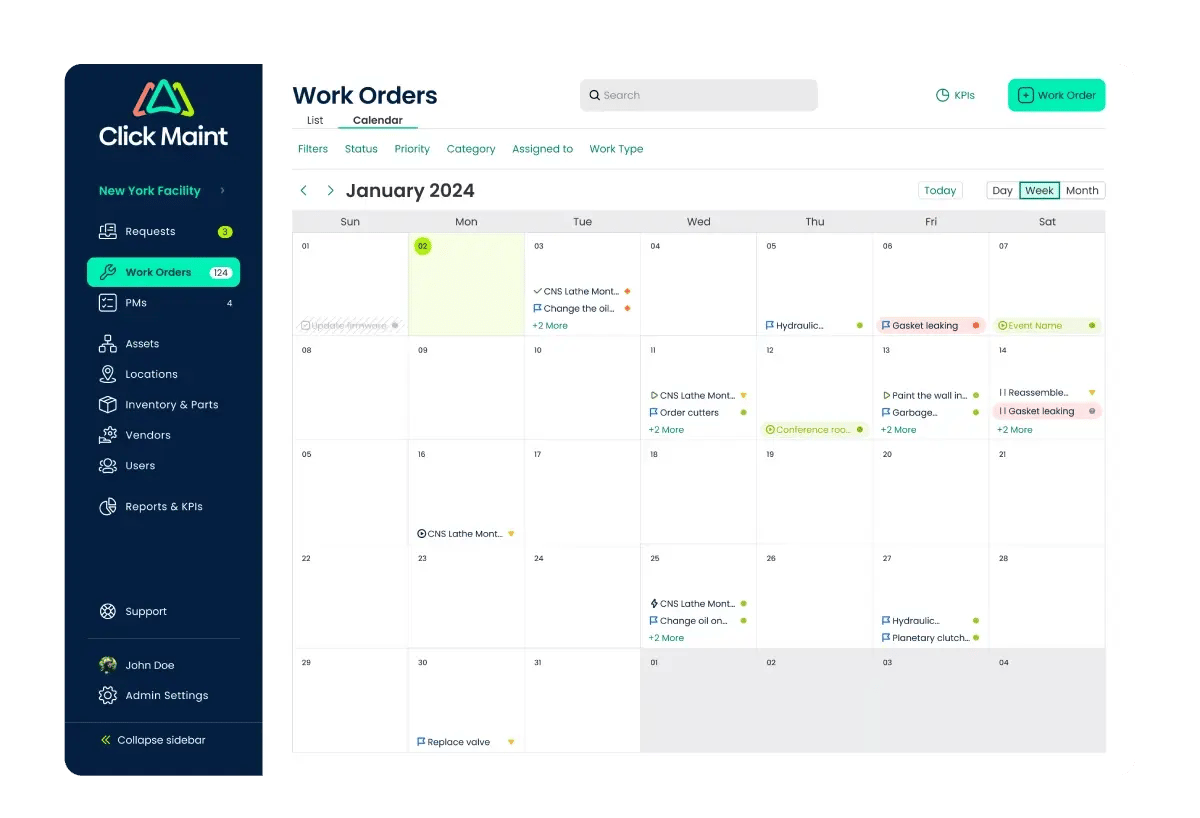

Create, assign, and track work orders, allowing you to monitor progress and ensure fast response and completion times. (Add filters)

Create, assign, and track work orders, allowing you to monitor progress and ensure fast response and completion times. (Add filters)

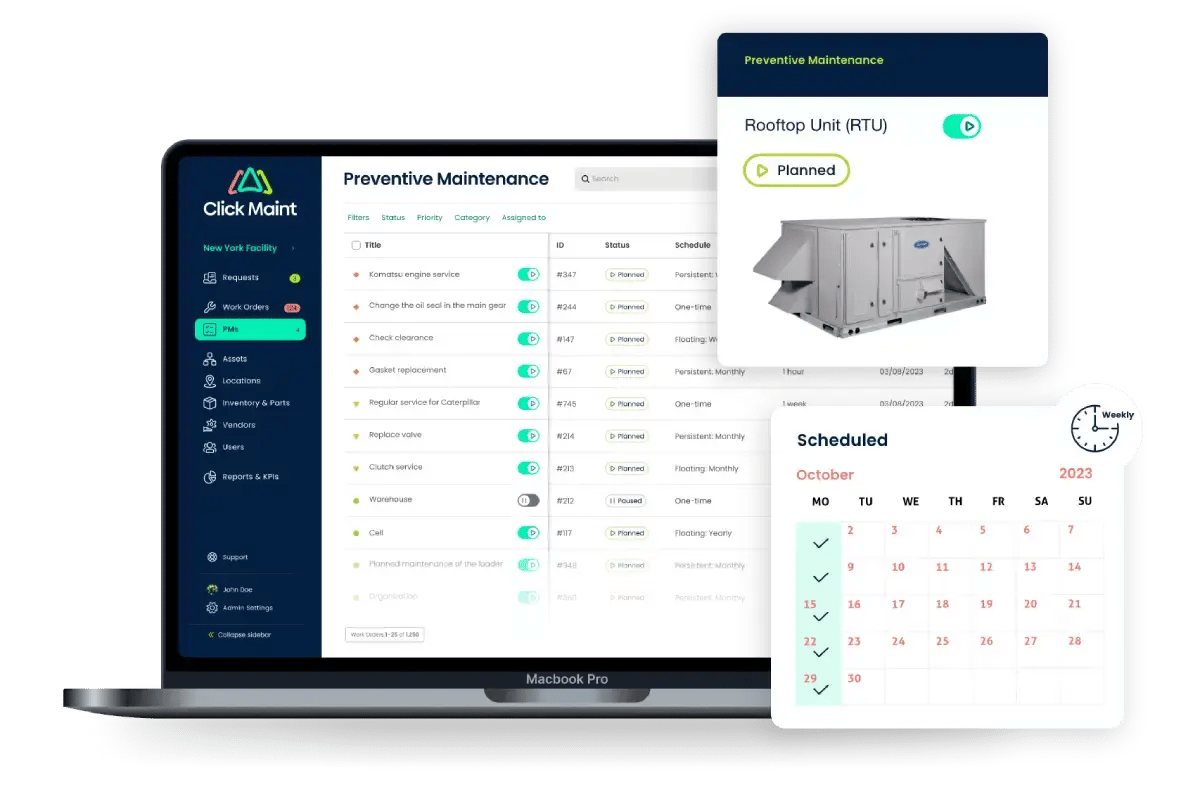

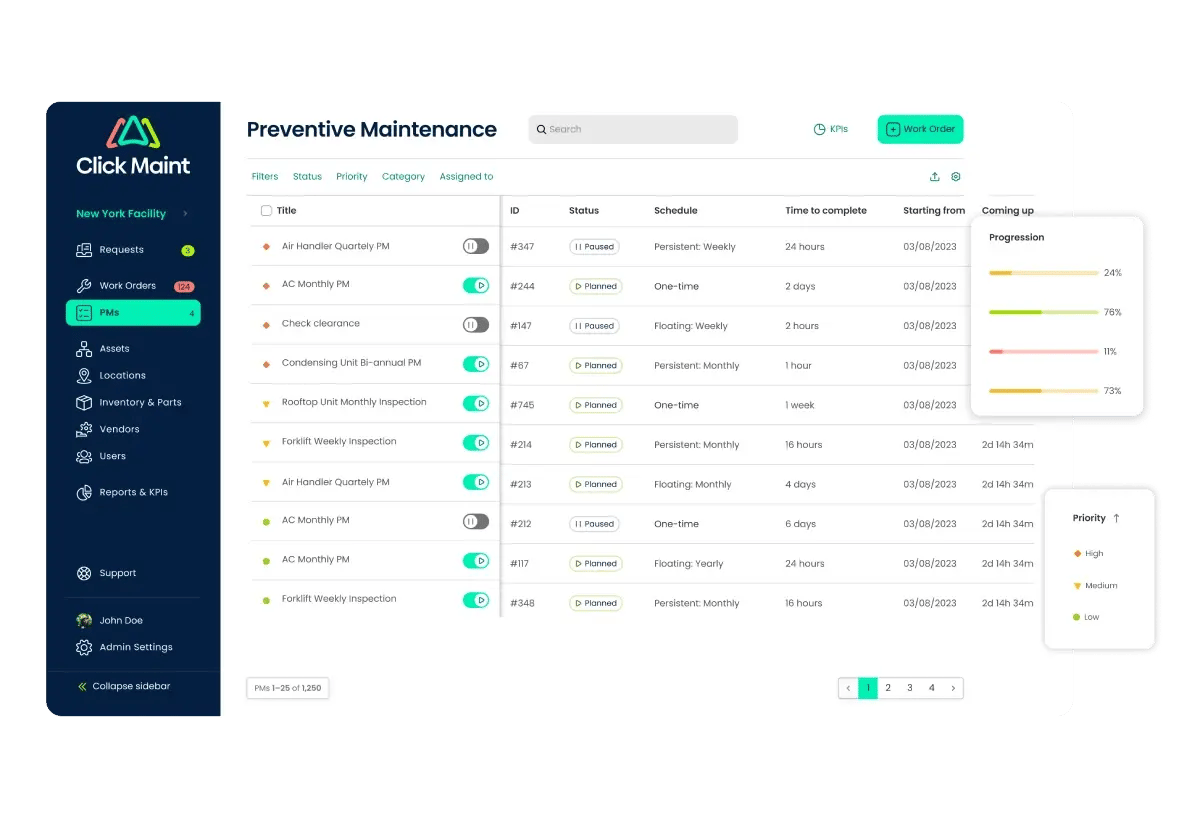

Schedule routine maintenance and inspections to prevent equipment failures and unplanned downtime and extend the lifespan of assets.

Schedule routine maintenance and inspections to prevent equipment failures and unplanned downtime and extend the lifespan of assets.

Plan and organize maintenance tasks, including preventive maintenance and inspections to reduce equipment downtime and improve efficiency, extend equipment life, and reduce repair costs.

Plan and organize maintenance tasks, including preventive maintenance and inspections to reduce equipment downtime and improve efficiency, extend equipment life, and reduce repair costs.

Equip maintenance teams with an easy-to-use mobile app that empowers users to manage work orders and tasks on the go. Users can scan QR codes, upload images, use voice to text, and more.

Equip maintenance teams with an easy-to-use mobile app that empowers users to manage work orders and tasks on the go. Users can scan QR codes, upload images, use voice to text, and more.

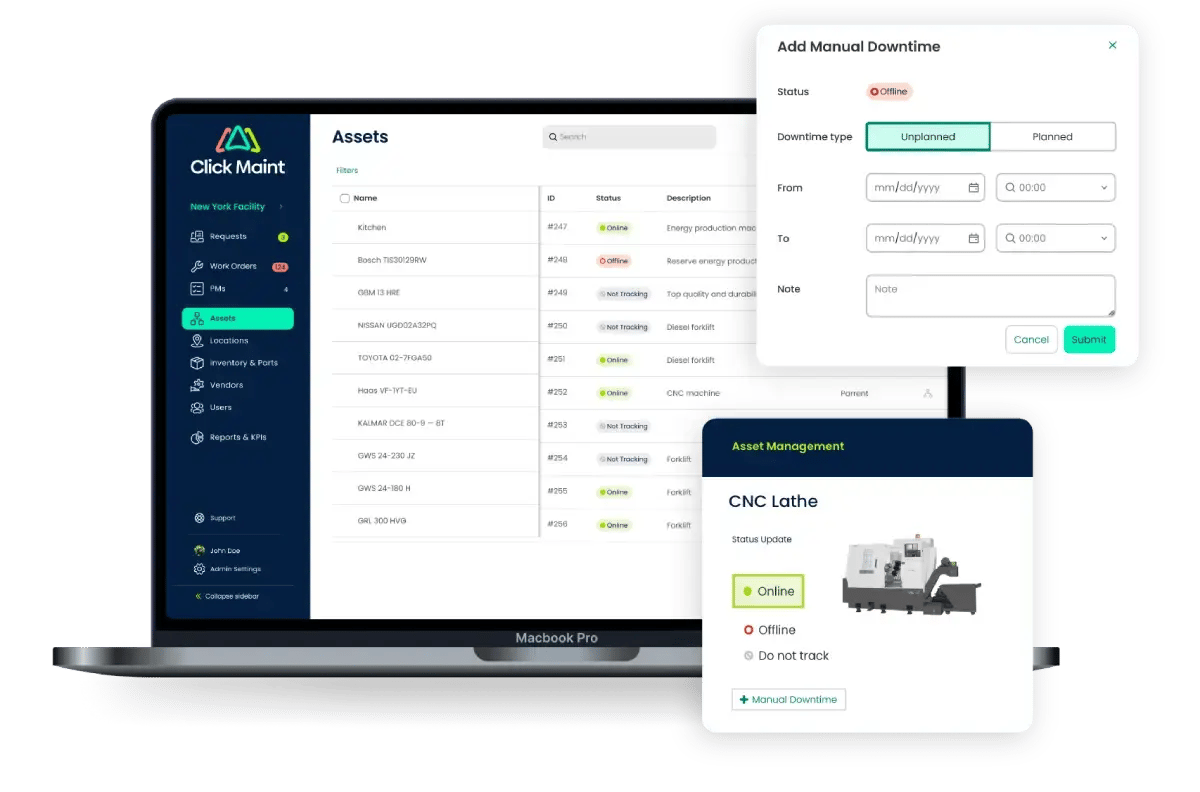

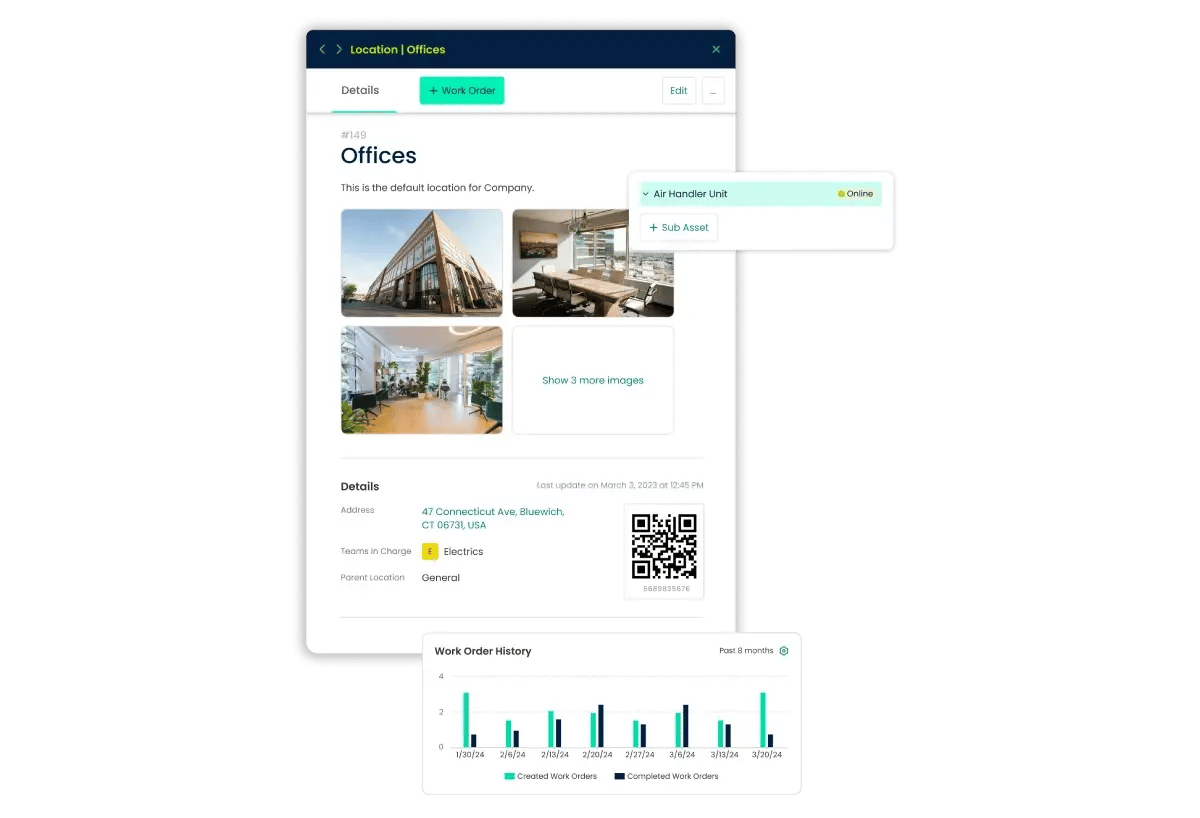

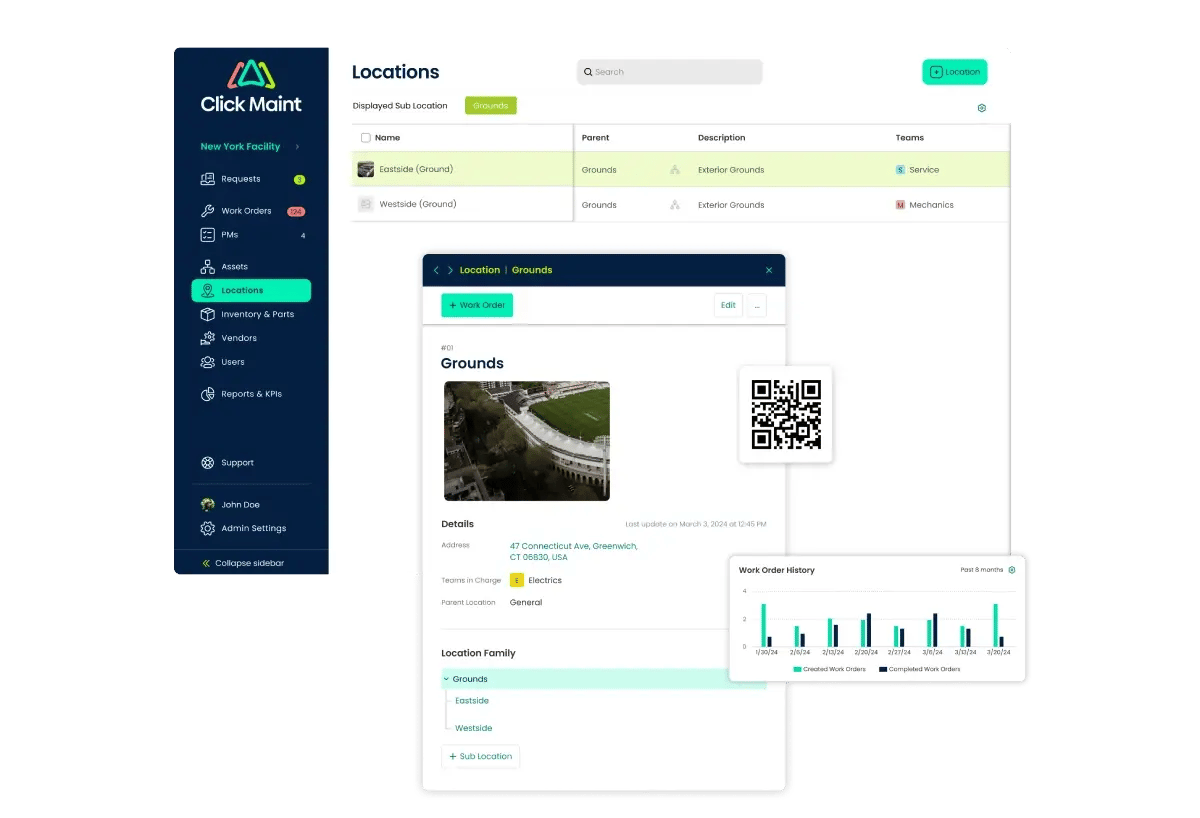

Keep track of assets, including their location, condition, and maintenance history, to streamline maintenance planning and improve asset longevity.

Keep track of assets, including their location, condition, and maintenance history, to streamline maintenance planning and improve asset longevity.

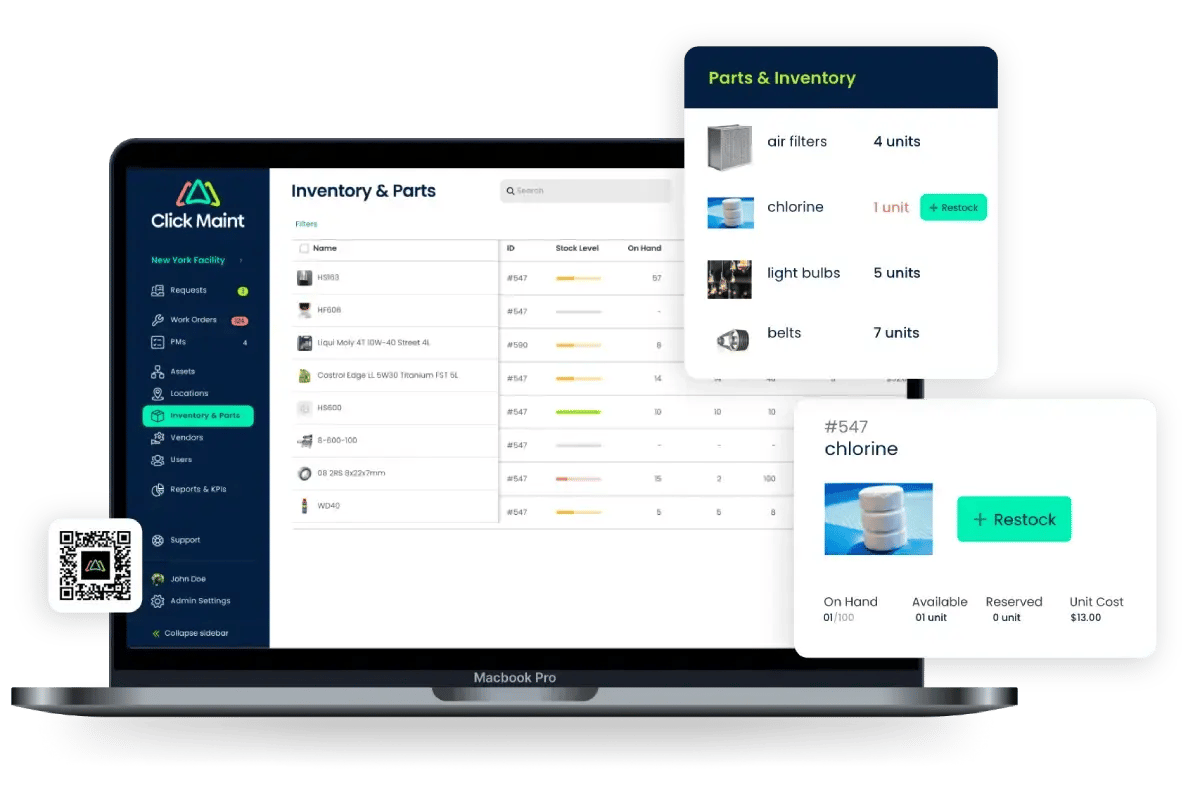

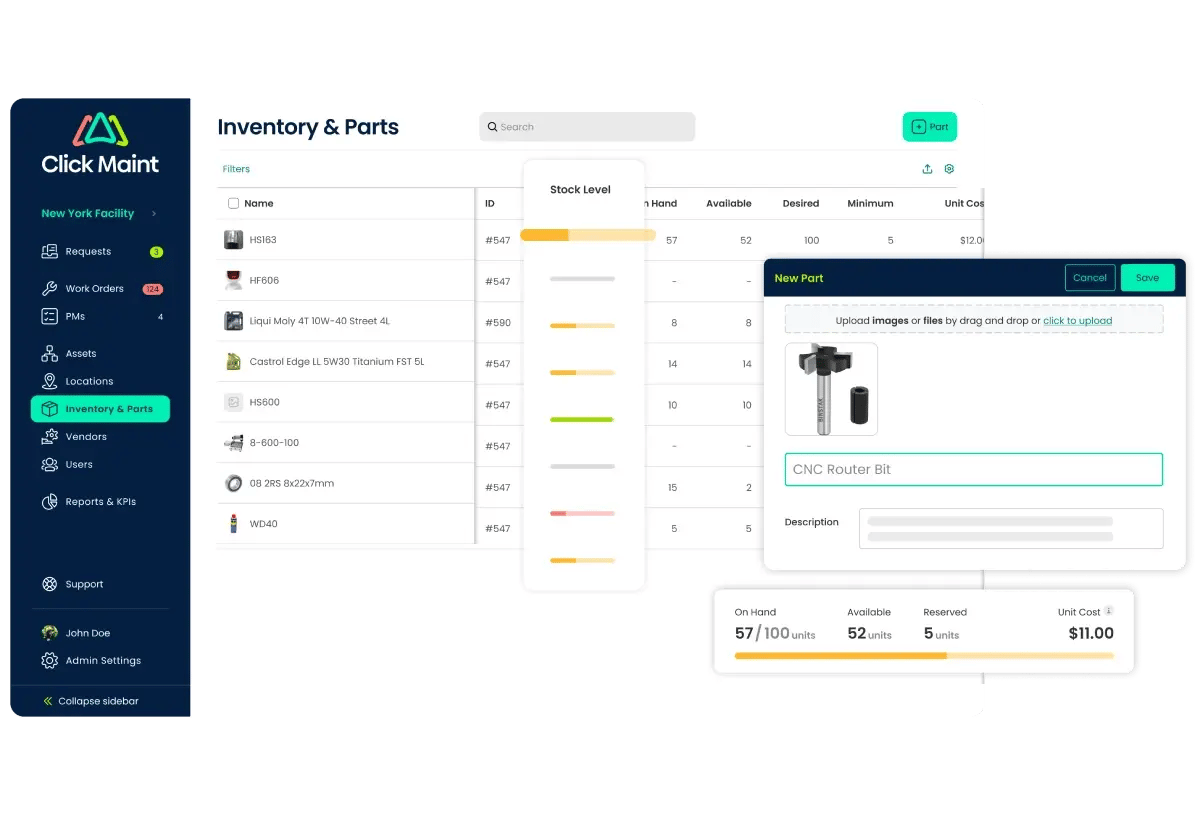

Manage spare parts, materials, and maintenance supplies, ensuring you have the right items in stock when needed to reduce downtime and delays when completing work.

Manage spare parts, materials, and maintenance supplies, ensuring you have the right items in stock when needed to reduce downtime and delays when completing work.

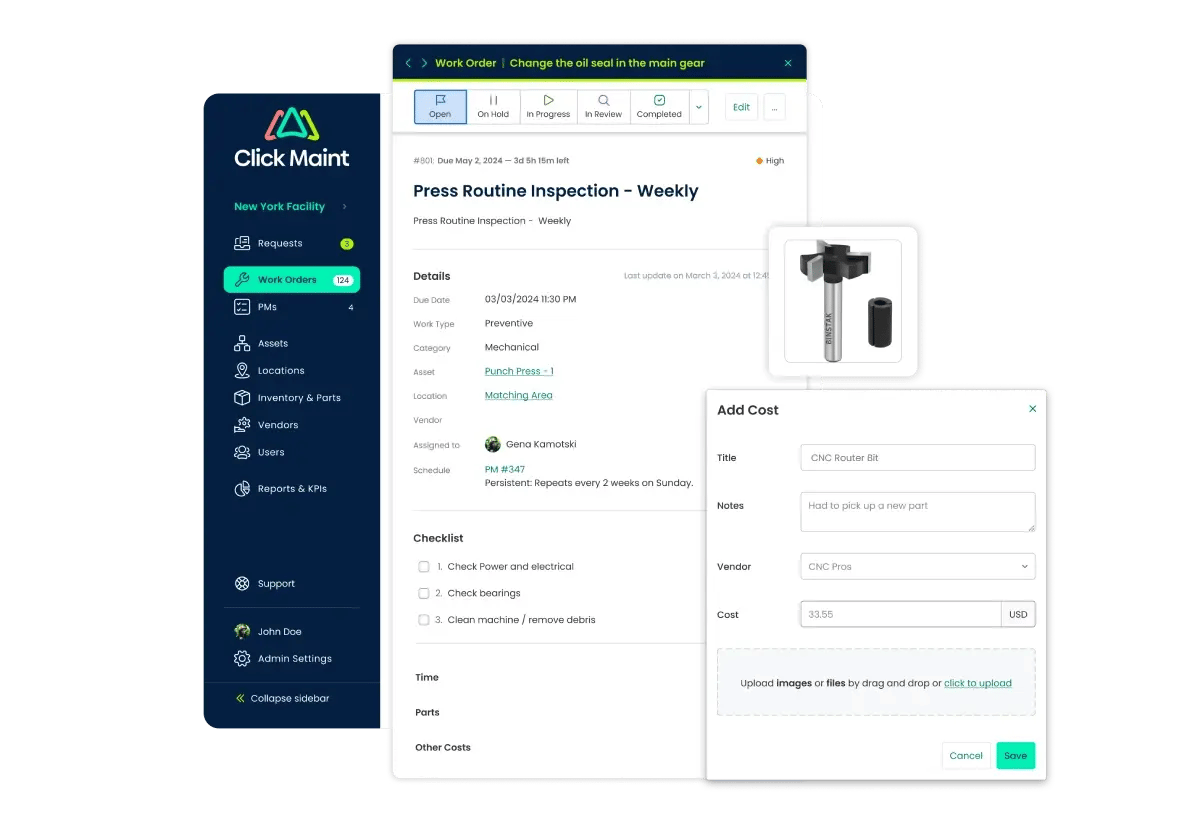

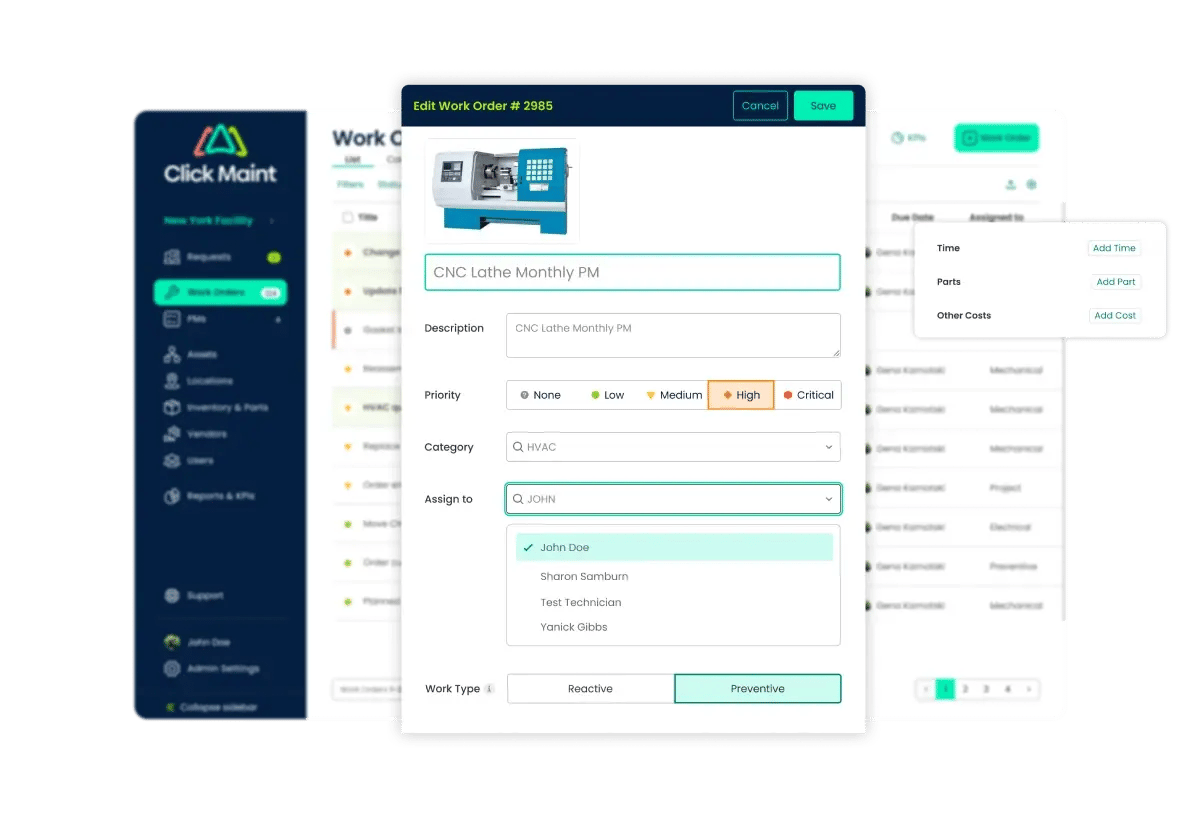

Track and estimate costs for maintenance tasks and work orders, enabling effective budgeting and cost management.

Track and estimate costs for maintenance tasks and work orders, enabling effective budgeting and cost management.

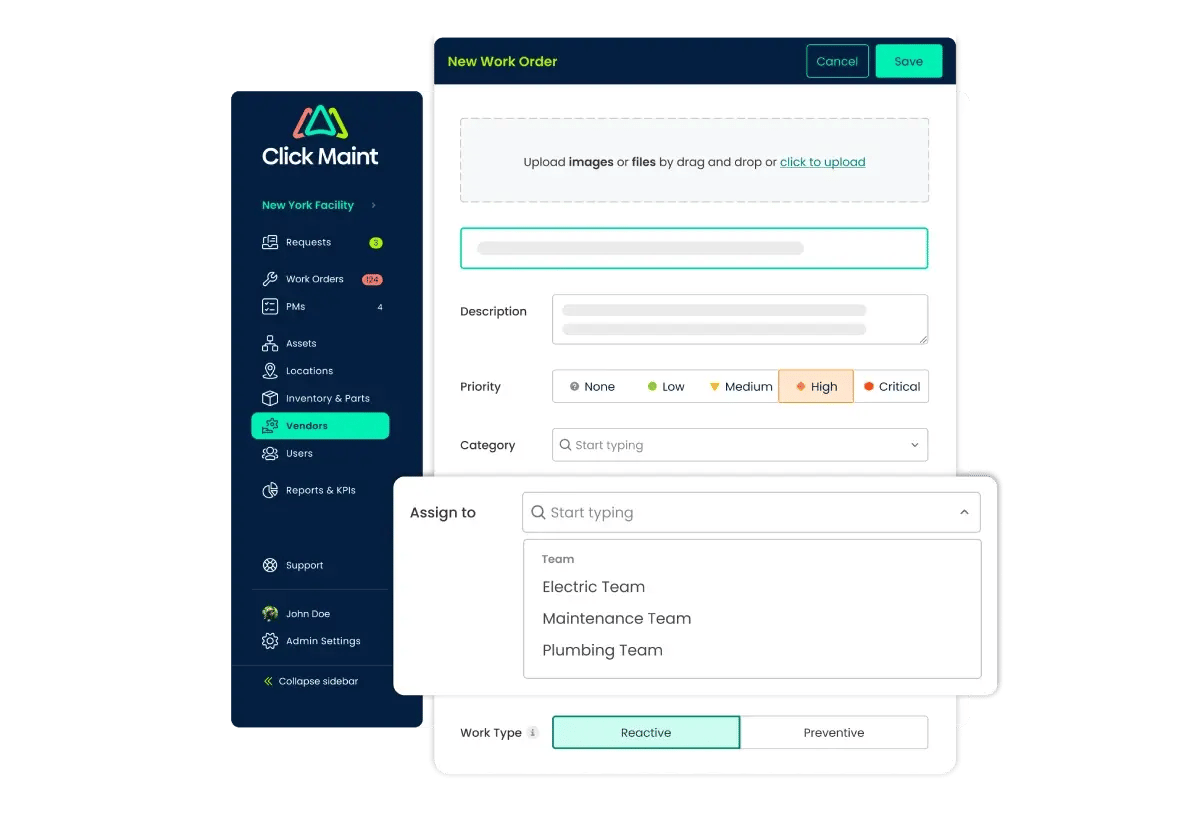

Coordinate the assignment and dispatch of maintenance teams, optimizing maintenance scheduling and planning and response time for service requests.

Coordinate the assignment and dispatch of maintenance teams, optimizing maintenance scheduling and planning and response time for service requests.

Manage maintenance tasks and work orders specific to commercial and residential buildings, ensuring building upkeep and high-quality service.

Manage maintenance tasks and work orders specific to commercial and residential buildings, ensuring building upkeep and high-quality service.

Oversee maintenance jobs from assignment to completion, ensuring tasks are completed on schedule and follow standard procedures.

Oversee maintenance jobs from assignment to completion, ensuring tasks are completed on schedule and follow standard procedures.

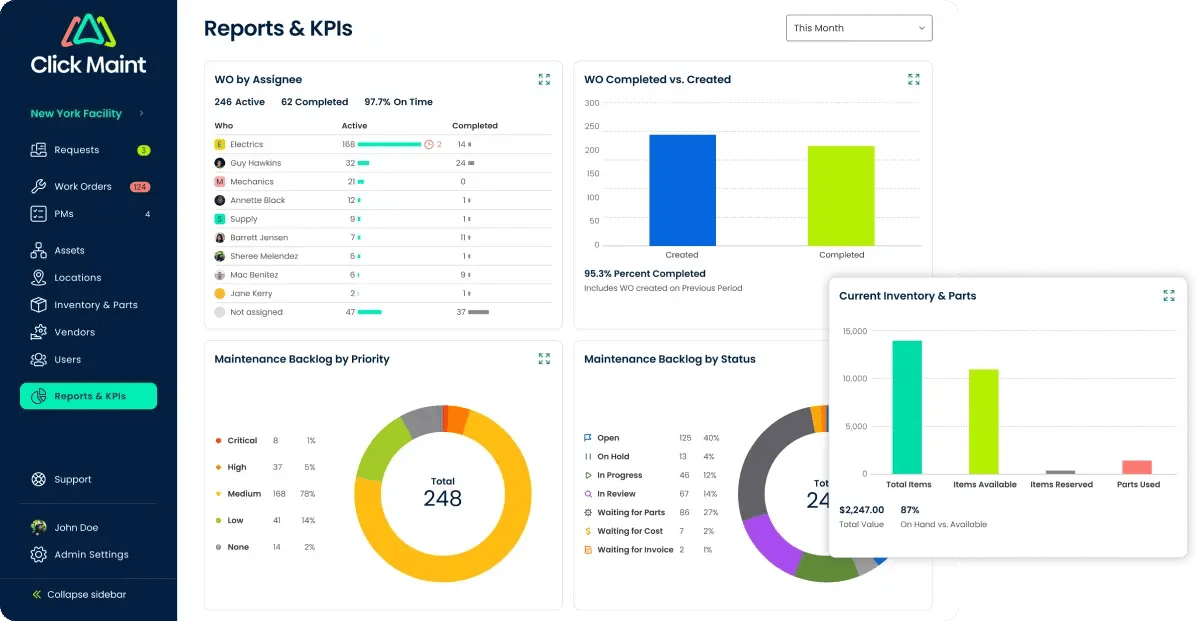

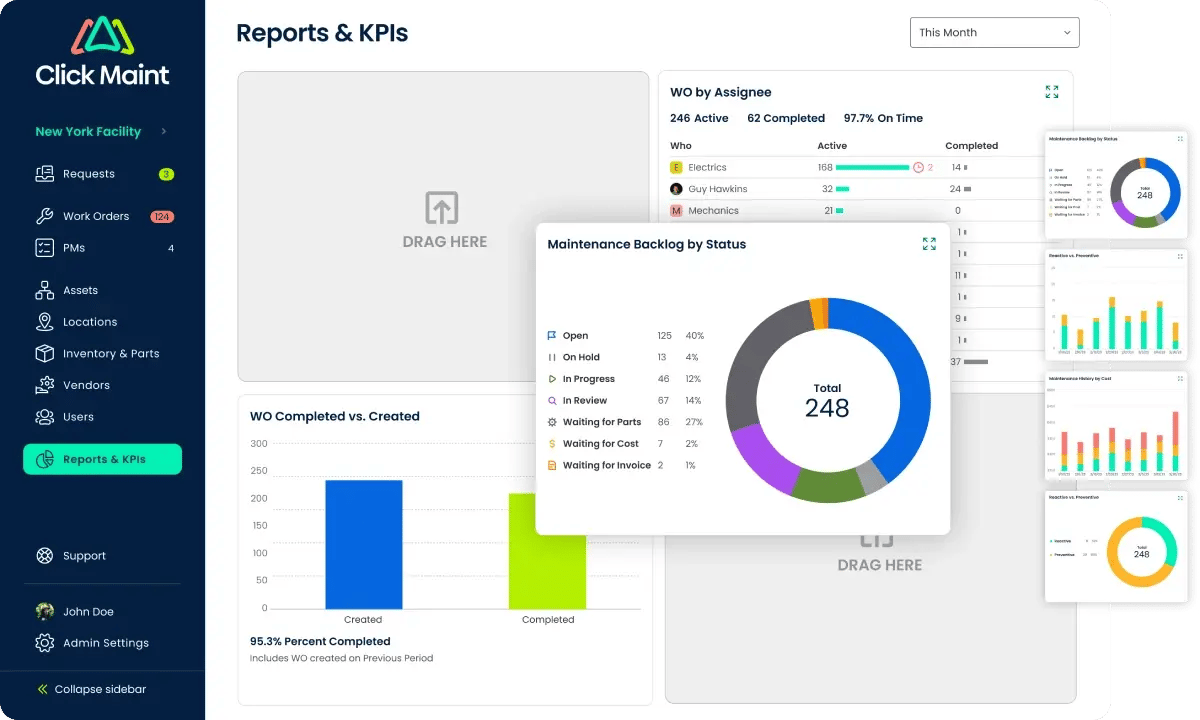

Generate reports and analyze maintenance data to identify trends, improve processes, and support data-driven decision-making.

Generate reports and analyze maintenance data to identify trends, improve processes, and support data-driven decision-making.

Maintain detailed records of past maintenance activities, supporting audits, compliance, and future maintenance planning.

Maintain detailed records of past maintenance activities, supporting audits, compliance, and future maintenance planning.

Manage maintenance personnel, including task assignment, scheduling, skills tracking, performance, and labor cost and utilization.

Manage maintenance personnel, including task assignment, scheduling, skills tracking, performance, and labor cost and utilization.

Oversee all aspects of facility maintenance, including equipment management, incident response, and vendor relationships.

Oversee all aspects of facility maintenance, including equipment management, incident response, and vendor relationships.

Automate the scheduling of recurring maintenance tasks, ensuring consistency and reduced manual effort.

Automate the scheduling of recurring maintenance tasks, ensuring consistency and reduced manual effort.

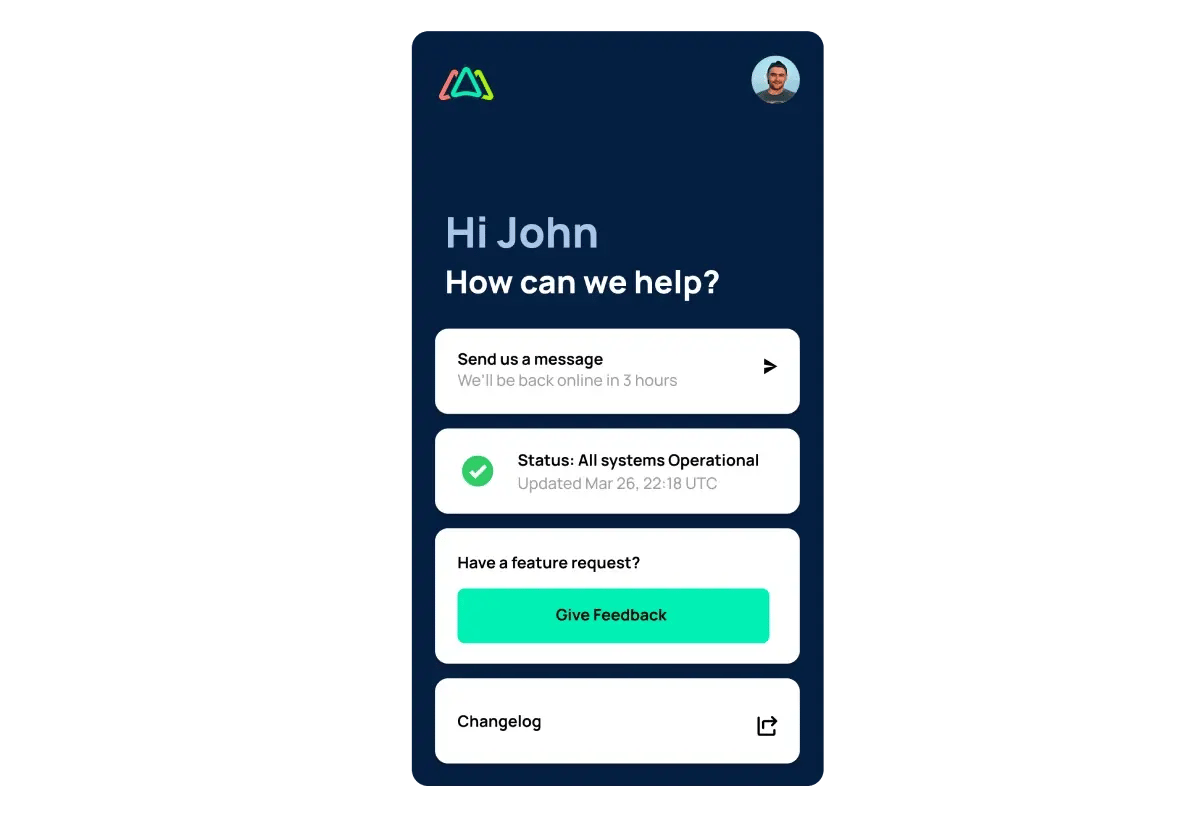

Access support resources and training materials from our knowledge base and Youtube channel to help users get the most out of the CMMS software.

Access support resources and training materials from our knowledge base and Youtube channel to help users get the most out of the CMMS software.

Use automated reminders and to-do lists to ensure maintenance tasks are completed on time and with consistency.

Use automated reminders and to-do lists to ensure maintenance tasks are completed on time and with consistency.

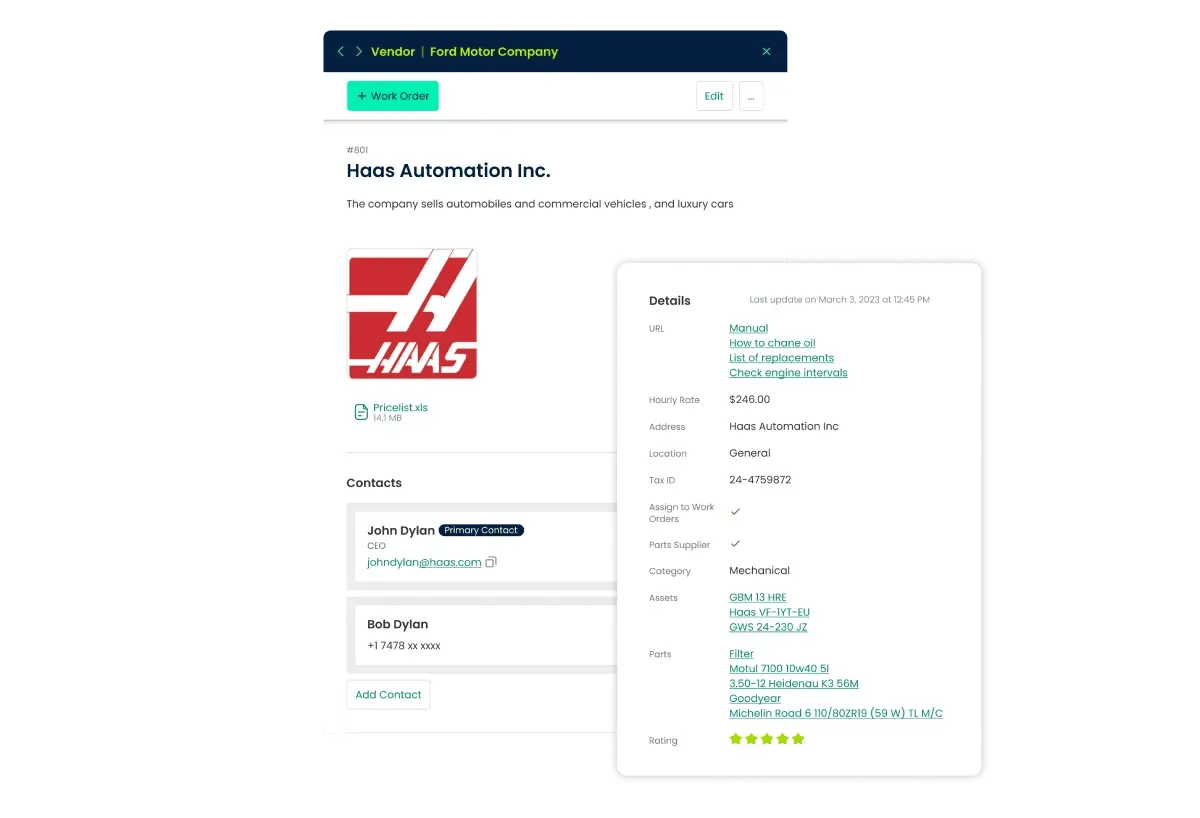

Coordinate with external vendors, managing service contracts and ensuring timely delivery of materials and services.

Coordinate with external vendors, managing service contracts and ensuring timely delivery of materials and services.

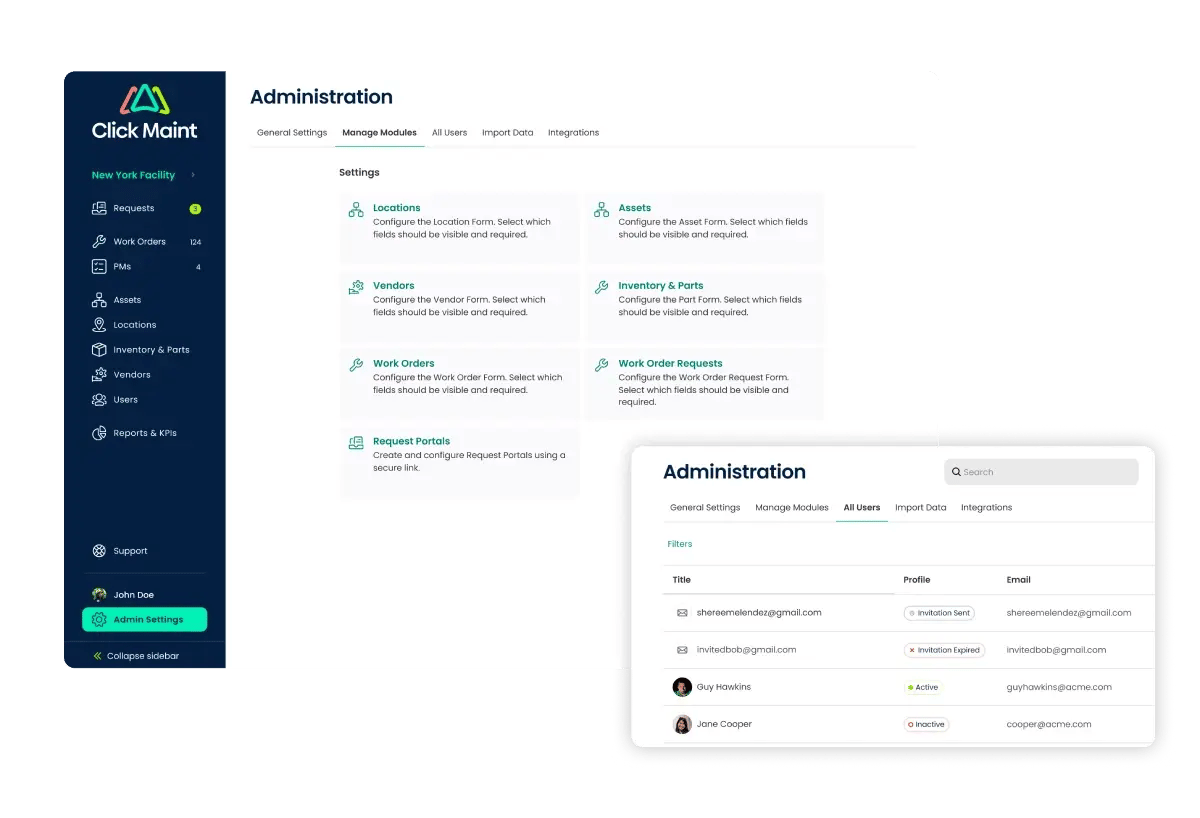

Define user roles and permissions to ensure data security and control access to sensitive information.

Define user roles and permissions to ensure data security and control access to sensitive information.

Configure dashboards to display key performance indicators (KPIs) and other important metrics for quick insights.

Configure dashboards to display key performance indicators (KPIs) and other important metrics for quick insights.

Disclaimer- The information provided in this feature comparison has been sourced from multiple review websites. We do not guarantee the accuracy or completeness of the information and advise the user to exercise discretion and make an informed decision while choosing a solution.

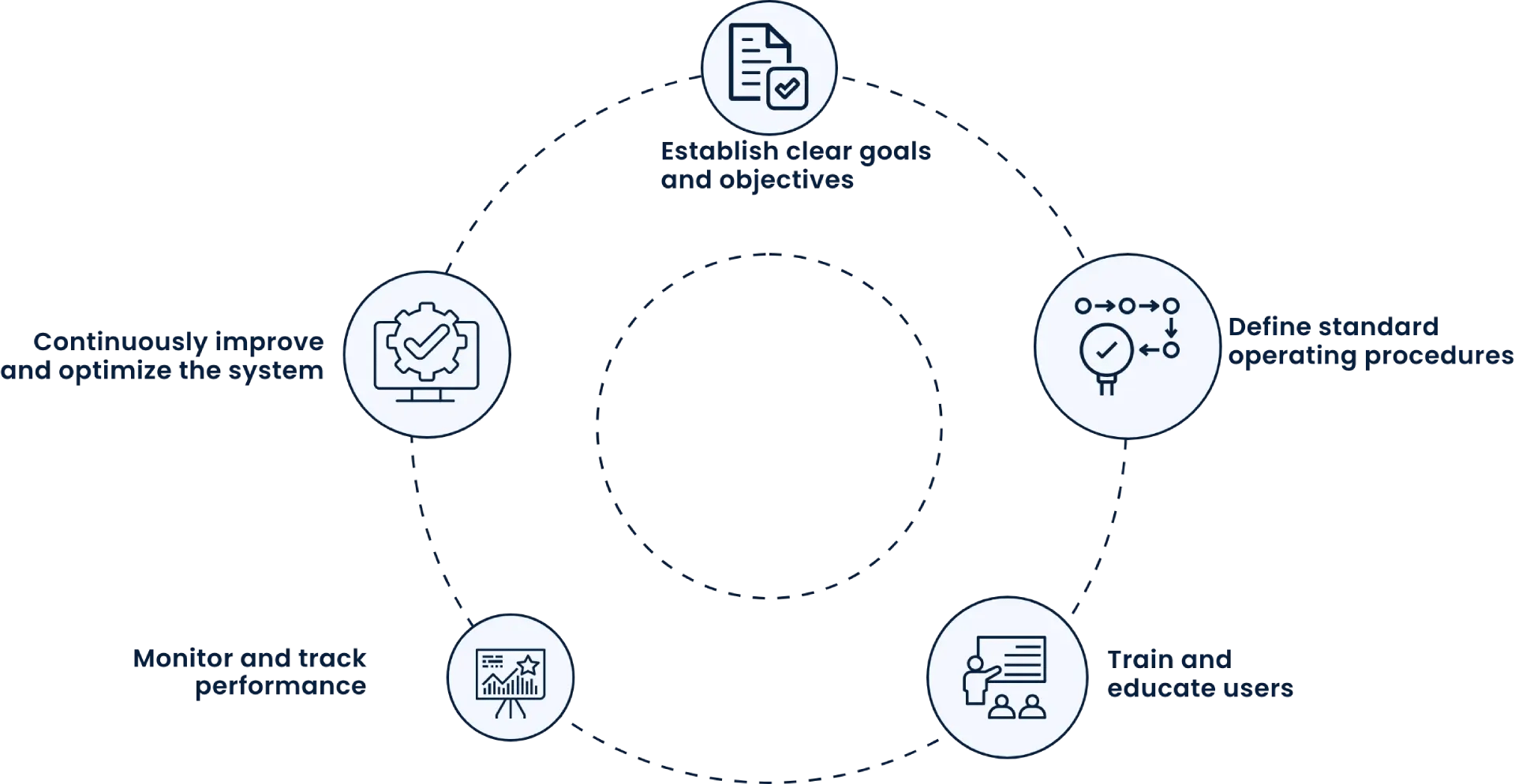

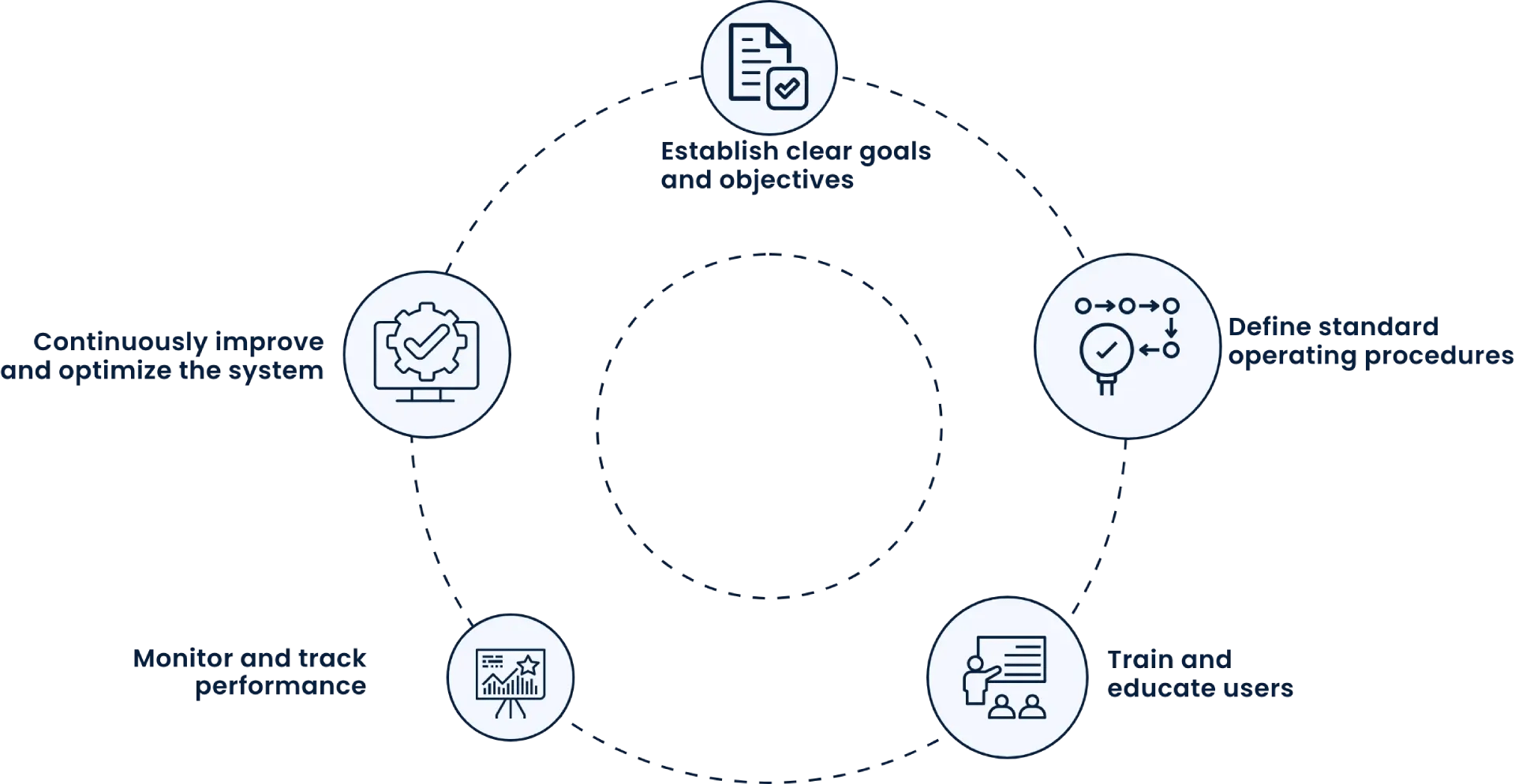

A Walk-through of the CMMS Workflow for Your Business

The first step is to identify all the assets that need to be maintained or repaired. These assets can include equipment, facilities, vehicles, or any other physical assets.

Once the assets are identified, their data is entered into the CMMS Software. This data can include details such as the asset's location, manufacturer, model number, purchase date, warranty information, maintenance history, and any other relevant information.

When a maintenance or repair task is needed, a work order is created in the CMMS. This work order contains information about the asset to be serviced, the type of maintenance required, the priority level, and any other details.

The work order is then assigned to a technician or a group of technicians based on their skills, availability, and workload.

The technician receives the work order and begins performing the necessary maintenance or repairs. They can use the CMMS to access information about the asset, view any previous maintenance or repair work that was done, and record any new information.

Once the maintenance or repair work is completed, the technician updates the work order status in the CMMS, indicating that the work is done and any parts used are accounted for.

The CMMS software generates reports and analysis on maintenance activities, asset performance, and costs. These reports can be used to identify trends, optimize maintenance schedules, and make data-driven decisions.

Based on the insights gained from the reports and analysis, the maintenance team continuously improves their processes and optimizes their maintenance strategies to reduce downtime and increase asset reliability.

Use Cases

PM software helps manufacturers optimize equipment uptime, reduce maintenance costs, and ensure compliance with safety regulations.

Healthcare facilities maintain critical medical equipment, ensuring patient safety and regulatory compliance while also reducing downtime and repair costs.

Transportation companies keep their vehicles and equipment in optimal condition, reducing downtime and repair costs while also ensuring compliance with safety regulations.

Facilities managers maintain critical building systems, reducing downtime, and minimizing repair costs, while also ensuring compliance with safety regulations and extending the lifespan of assets.

Farmers maintain their equipment, increasing efficiency, reducing downtime, and ensuring compliance with safety regulations, ultimately leading to improved crop yields and profitability.

Industrial CMMS software helps energy companies manage their complex infrastructure and equipment, ensuring high levels of uptime, safety, and regulatory compliance.

Colleges and universities maintain their campus buildings and equipment, ensuring student safety, reducing downtime and minimizing repair costs.

CMMS software helps hotels and resorts maintain their properties, ensuring guest satisfaction and minimizing disruptions to operations.

Stadiums and arenas maintain their facilities and equipment, ensuring a positive guest experience, reducing downtime, and minimizing repair costs.

Cities and towns maintain their public infrastructure, ensuring safety, reducing downtime, and minimizing repair costs, ultimately leading to improved quality of life for residents.

CMMS software helps retailers and restaurant owners maintain their buildings and equipment, ensuring customer satisfaction, reducing downtime, and minimizing repair costs.

Learn more about CMMS software for retail maintenance.

CMMS software helps religious institutions and non-profits maintain their facilities and equipment, ensuring facilities are safe, running efficiently and minimizing repair costs.

More on church maintenance software.

Fueling Maintenance Expertise

Efficiently plan and schedule maintenance tasks, track work orders, and allocate resources effectively with a CMMS. Get real-time visibility into maintenance activities to make data-driven decisions, optimize maintenance processes, and improve overall equipment reliability.

Receive clear work instructions, access to historical maintenance data, and real-time notifications for assigned tasks with a CMMS. Easily record your work progress, update maintenance records, and collaborate with other team members to achieve improved efficiency and effective troubleshooting.

Access comprehensive asset information, including maintenance history, criticality, and lifecycle data within a CMMS. Make informed decisions regarding asset performance, maintenance strategies, and replacement planning to optimize asset utilization.

Automate inventory tracking, generate purchase orders, and optimize stock levels through a CMMS. Ensure that the right parts are available when needed, reduce stockouts and excess inventory. Streamline procurement processes, lower costs, and enhance inventory management efficiency.

Maintain accurate records of maintenance activities, regulatory inspections, and certifications with a CMMS software. Access documentation, track compliance status, and ensure compliance with industry standards, safety regulations, and audit requirements.

Get real-time insights into equipment performance, maintenance costs, and downtime metrics through a CMMS software. Identify bottlenecks, optimize maintenance schedules, and make informed decisions to improve operational efficiency, and enhance overall equipment effectiveness.

Get cost data related to maintenance activities, equipment repairs, and spare parts usage within a CMMS. Facilitate accurate cost tracking, budgeting, and forecasting for maintenance operations. Optimize spending, identify cost-saving opportunities, and demonstrate the financial value of maintenance investments.

Maintain a safe and compliant work environment, track safety inspections, record incidents, and manage corrective actions. Enhance visibility into safety-related maintenance tasks and ensure timely completion of safety requirements. Effectively monitor safety performance, mitigate risks, and improve overall workplace safety.

Everything you need to know

A Computerized Maintenance Management System (CMMS) is a software application that helps organizations manage their maintenance operations by keeping track of all the assets, equipment, and facilities that need maintenance. CMMS software is designed to be a centralized database that stores all the maintenance-related information, including work orders, maintenance history, spare parts inventory, and preventive maintenance schedules.

A CMMS (Computerized Maintenance Management System) is software that helps organizations manage maintenance activities, track assets, and improve operational efficiency, ultimately aiming to reduce downtime and costs.

CMMS Software growth has been rapid in the last few years across industries especially manufacturing. Do no miss reading the CMMS Software trends.

Work Order Management: Facilitates the creation, tracking, and completion of maintenance work orders.

Asset Tracking: Manages and organizes information about assets, including their location, maintenance history, and specifications.

Inventory Management: Tracks spare parts and other materials used in maintenance activities.

Scheduling and Planning: Helps plan and schedule maintenance tasks, ensuring optimal resource allocation and minimizing downtime.

Reporting and Analytics: Provides data and reports to track maintenance performance and identify areas for improvement.

The main purpose of a CMMS is to improve the efficiency and effectiveness of maintenance operations by providing real-time visibility into the status of assets and work orders. This helps maintenance teams prioritize their tasks, reduce downtime, and increase the lifespan of their assets. A CMMS also enables organizations to move from a reactive maintenance approach to a proactive one, where maintenance is planned and scheduled based on data-driven insights.

Top questions to ask when choosing maintenance software

1) What problems are we hoping to solve with a CMMS?

2) Does it have all the features we need?

3) Is it mobile compatible?

4) Can the software scale with your business?

5) What types of reports can be generated using the system?

Click Maint CMMS. 4.7 / 5. Pricing. $35 per user per month. Free Trial. (best cmms software click maint)

UpKeep CMMS. 4.6 / 5. Pricing. Starts at $45 per user per month. Free Trial. Free demo. (Try UpKeep alternatives)

eMaint. 4.5 / 5. Pricing. $69 per user per month. Free Trial. Free demo. (Try eMaint alternatives)

Wrike. 4.15 / 5. Pricing. $10 per user per month. Free Trial.

Redlist. 4.8 / 5. Pricing. Starts at $60 per user per month. Free demo. (Try Redlist alternatives)

Brightly. 4.4 / 5. Pricing available on request. Free Trial. Free demo. (Try Brightly alternatives)

MicroMain. 4.5 / 5. Pricing. Starts at $89 per user per month. Free Trial. Free demo. (Try MicroMain alternatives)

LLumin. 4.5 / 5. Pricing. Starts at $45 per user per month. Free Trial. Free demo. (Try LLumin alternatives)

Coast. 5.0 / 5. Pricing. Starts at $60 per user per month. Free Trial. Free demo. (Try Coast alternatives)

Maintenance Connection. 4.4 / 5. Pricing. Starts at $110 per user per month. Free Trial. Free demo. (Try Maintenance Connection alternatives)

Maintenance Care. 4.8 / 5. Pricing. $100 per month (unlimited users). Free Trial. Free demo. (Try Maintenance Care alternatives)

FMX. 4.75 / 5. Pricing available on request. Free Trial. Free demo. (Try FMX alternatives)

CMMS software is typically not free, as it involves significant development, maintenance, and support costs. However, some companies offer free or freemium versions of CMMS with limited features or user capacity. These free versions can be a good starting point for small businesses or those with basic needs, but they usually require an upgrade to a paid version for more advanced features, additional users, or dedicated support. Learn more about them in our free cmms software blog.

If you're looking for a CMMS solution, consider your budget, the complexity of your maintenance operations, and the features you need. Free or freemium CMMS software might work for small-scale operations, but for more comprehensive maintenance management, investing in a paid version is often necessary.

Start your free trial today and discover everything Click Maint CMMS has to offer -

Maintenance management software is an essential component of any effective asset management strategy. This software, which includes CMMS solutions, goes beyond just tracking repairs and maintenance schedules. It helps organizations with asset lifecycle management by enabling proactive and predictive maintenance, ensuring that equipment operates at peak efficiency. By organizing maintenance tasks, keeping detailed records, and offering real-time reporting, maintenance management software allows businesses to maintain a high level of operational continuity and minimize costly downtime.

One of the core benefits of maintenance management software is the ability to centralize all maintenance-related data into one easily accessible platform. This centralization facilitates better decision-making by providing insights into asset health, performance trends, and resource allocation. Maintenance managers can quickly identify which equipment is most likely to fail, where maintenance spending is most concentrated, and how to improve overall efficiency. Whether it’s through automated work orders, predictive maintenance alerts, or enhanced inventory management, maintenance management software provides a comprehensive view of operations that empowers organizations to operate more efficiently.

CMMS software supports predictive maintenance through:

Key performance indicators (KPIs) for evaluating CMMS platform effectiveness include:

The implementation time for a CMMS software depends on the size of the organization and the complexity of the maintenance operations. It can take a few weeks to several months.

Need a timeline? Here are the important cmms software implementation steps.

Organizations may encounter several challenges during CMMS implementation:

Consider engaging cmms implementation services for complex workflows.

The return on investment (ROI) for CMMS can vary widely but generally includes:

Organizations often report ROI ranging from 10% to over 30% within the first year of implementation, depending on their specific circumstances.

The two main types of CMMS are On-premise CMMS and Cloud-based CMMS.

On-Premise CMMS is installed and hosted on a company's own servers or data centers. It offers more control over data security and customization but requires internal IT infrastructure and maintenance. Organizations with strict data compliance requirements or unique customization needs often prefer on-premise CMMS.

Cloud-Based CMMS, also known as Software as a Service (SaaS), is hosted on remote servers and accessed via the internet. It typically offers greater flexibility, scalability, and easier updates, with lower upfront costs. Cloud-based CMMS is popular among businesses looking for quick deployment and reduced IT overhead. It also allows remote access, making it ideal for distributed teams or field-based operations.

Yes, training is necessary for successful adoption and use of a CMMS software. Training can be provided by the software vendor or by an in-house team.

Training resources typically include:

Customization varies by industry based on unique requirements:

CMMS (Computerized Maintenance Management System) in healthcare is a powerful tool that revolutionizes maintenance and facility management processes. Designed specifically for the unique needs of the healthcare industry, CMMS healthcare solutions ensure efficient operations, regulatory compliance, and optimal patient care.

With CMMS healthcare software, facilities can effectively manage preventive maintenance schedules, track and prioritize work orders, and streamline asset management. It enables healthcare organizations to proactively address maintenance needs, reducing downtime and enhancing the reliability of critical equipment.

In addition, CMMS healthcare systems provide comprehensive inventory management, enabling efficient tracking and procurement of medical supplies, reducing waste, and controlling costs. They also help in regulatory compliance by maintaining detailed records of maintenance activities, ensuring adherence to industry standards and guidelines.

CMMS healthcare solutions also offer real-time data and reporting capabilities, providing valuable insights into maintenance trends, resource allocation, and performance metrics. This data-driven approach allows for informed decision-making, optimizing resource utilization and driving continuous improvement in healthcare facility management.

From hospitals and clinics to long-term care facilities, CMMS healthcare solutions are transforming maintenance operations, improving efficiency, and ultimately enhancing patient safety and satisfaction. With streamlined processes and increased operational visibility, healthcare organizations can focus on what truly matters - delivering exceptional care to patients while maintaining the highest standards of facility management.

CMMS software helps organizations maintain compliance through:

By implementing CMMS software, small businesses can efficiently manage their maintenance operations, optimize resource allocation, and enhance productivity.

CMMS software for small businesses offers a range of features tailored to their specific needs. It enables the organization to schedule and track maintenance tasks, ensuring equipment and assets are properly maintained to avoid unexpected breakdowns and costly repairs.

With CMMS software, small businesses can create a centralized database of their equipment and inventory, including important details such as warranty information, service history, and documentation. This facilitates better inventory management, allowing businesses to track and reorder supplies when needed, reducing the risk of stockouts or excessive inventory.

By implementing CMMS software, small businesses can achieve significant cost savings by preventing equipment failures, minimizing downtime, and optimizing maintenance schedules. It also enables them to streamline their operations, enhance productivity, and focus on core business activities.

They can generate work orders, assign tasks to technicians or employees, and track their progress in real-time. This streamlines communication and collaboration within the organization, ensuring that maintenance activities are completed promptly and efficiently.

CMMS software for small businesses often includes reporting and analytics features. This allows businesses to gain insights into their maintenance operations, identify trends, and make data-driven decisions to optimize their maintenance strategies and allocate resources effectively.

Small businesses can effectively leverage CMMS by:

As your business grows, so will your maintenance needs. A scalable CMMS solution is crucial for companies that anticipate expansion, whether through adding more facilities, equipment, or users. Cloud-based CMMS software, in particular, offers unparalleled scalability, allowing businesses to easily expand their system’s capabilities without the need for costly hardware upgrades or complex installations.

With a scalable CMMS, businesses can start with basic functionality and gradually adopt more advanced features as their operations evolve. This flexibility makes CMMS ideal for companies of all sizes, from small businesses with a single location to large enterprises managing multiple sites worldwide. Whether you’re adding new assets or expanding your maintenance team, a scalable CMMS grows with you, ensuring that your maintenance processes remain efficient and effective at every stage of growth.

Want to explore open-source and free options? Check out our blog on the best free CMMS software to compare.

Mobile access enhances functionality by:

Here are some articles we recommend you also go through:

What is CMMS Software? | Meaning, Benefits, Features (link)

Which CMMS Software do you use? (Reddit link)