What is Inventory Management Software, and why is it important?

It is a technology that helps businesses track, organize, and optimize their inventory levels and ordering and consumption processes. It is important because it enables businesses to have real-time visibility into their inventory, prevents stock outages and overstocking, streamlines procurement, and improves overall operational efficiency.

How does Inventory Management Functionality work within a CMMS?

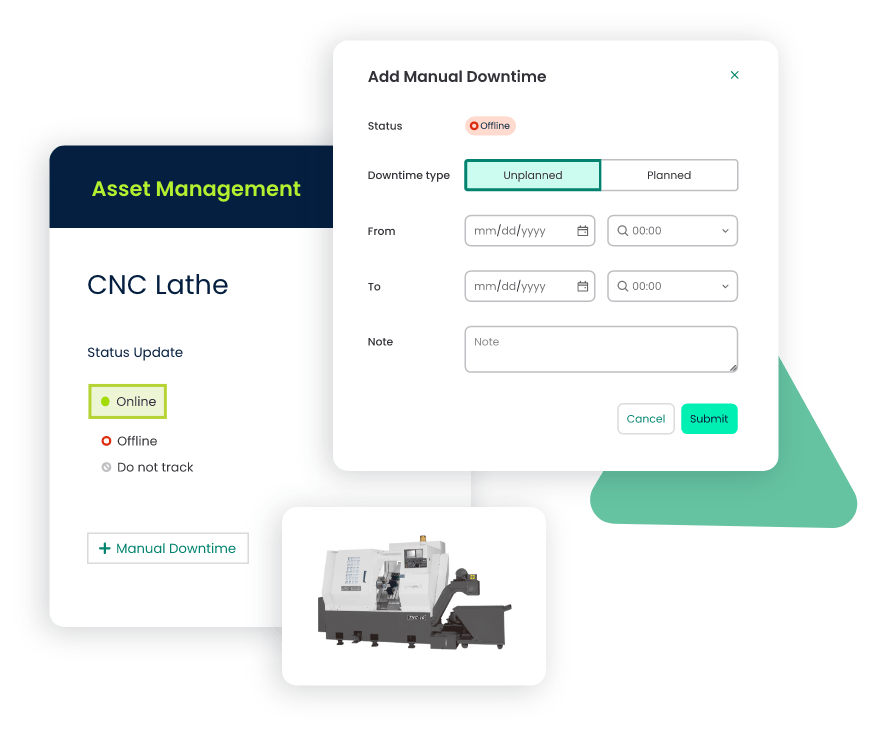

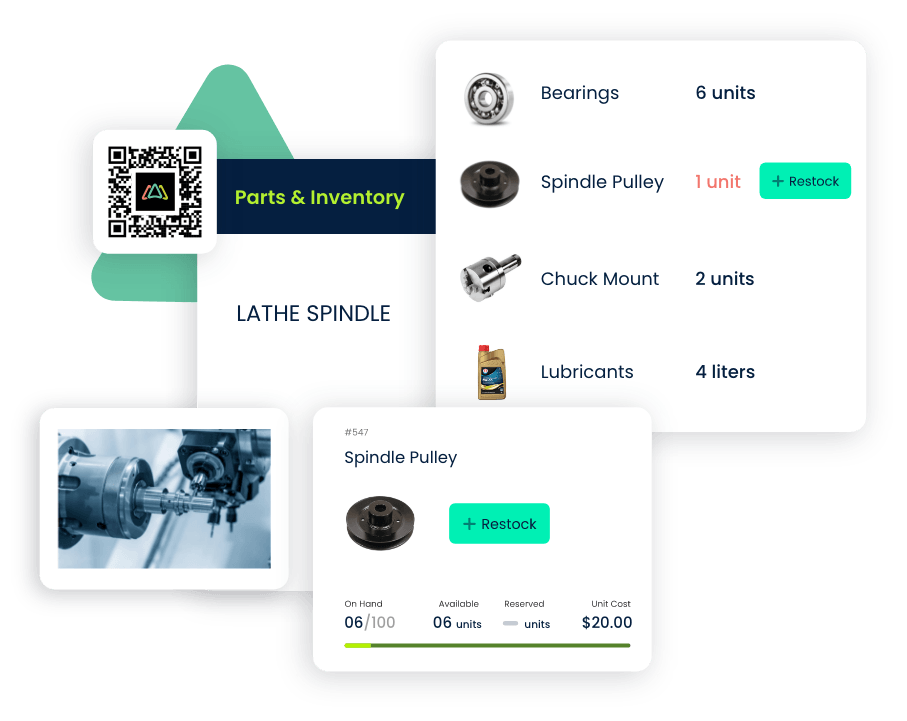

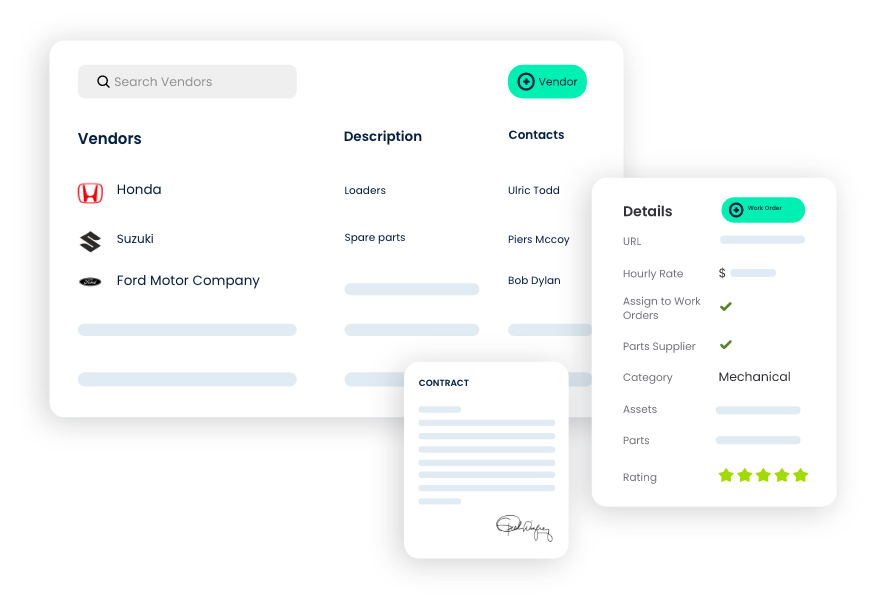

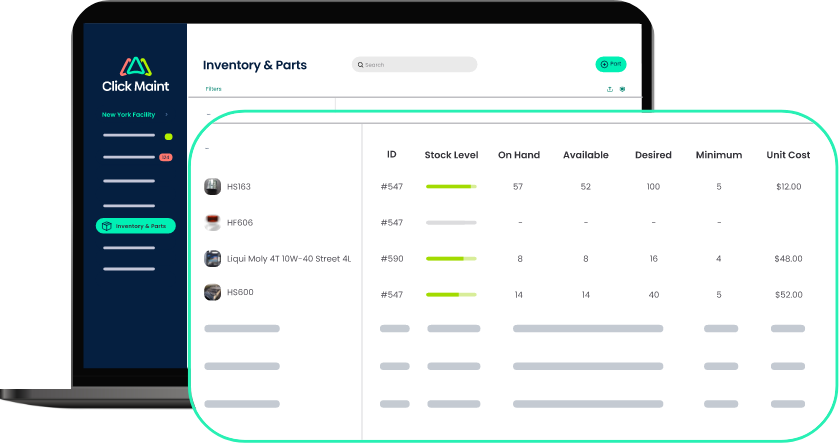

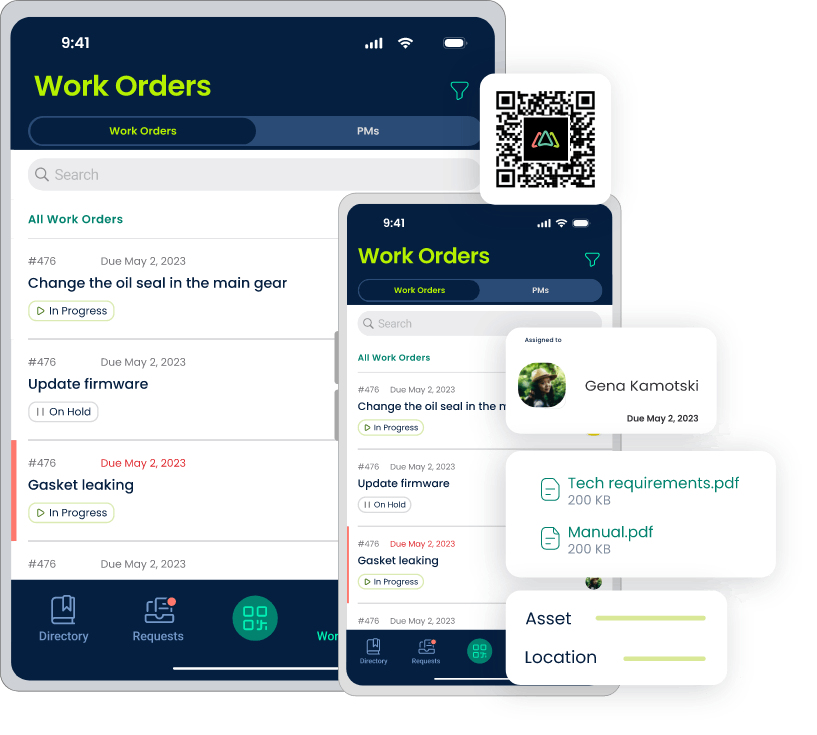

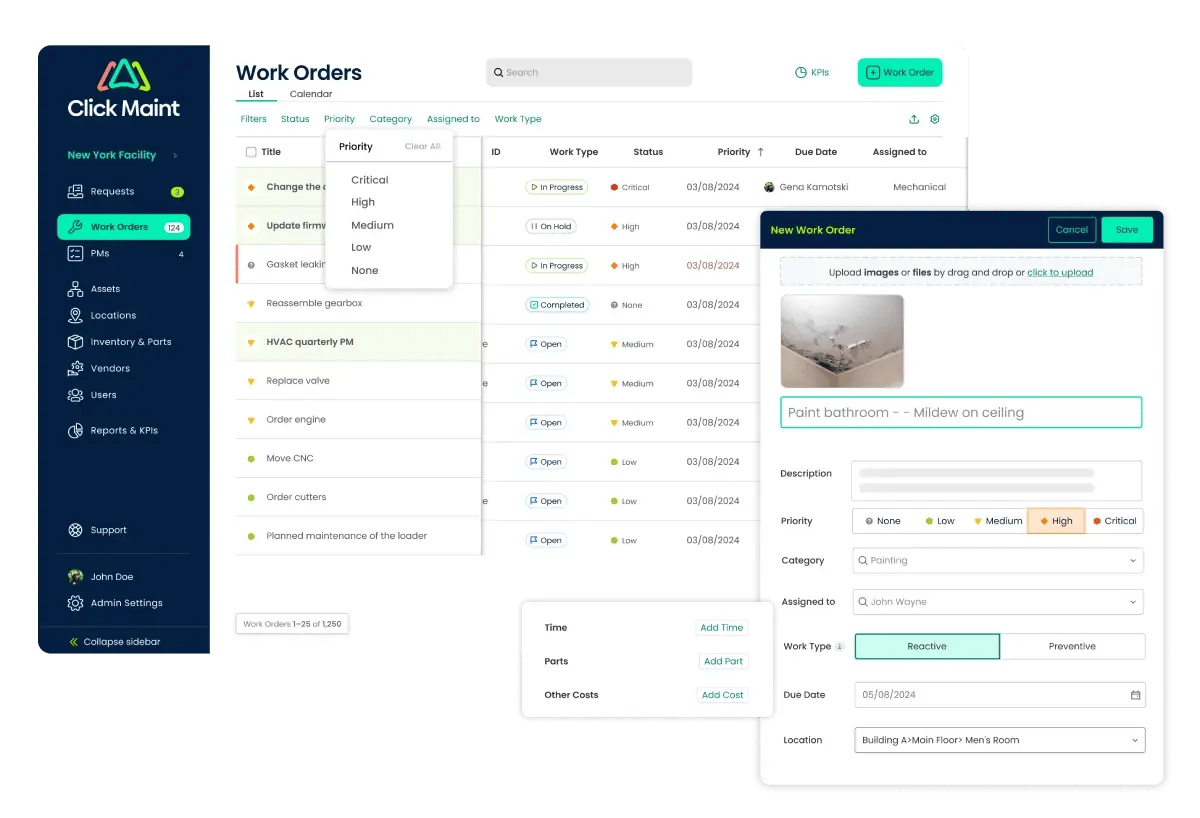

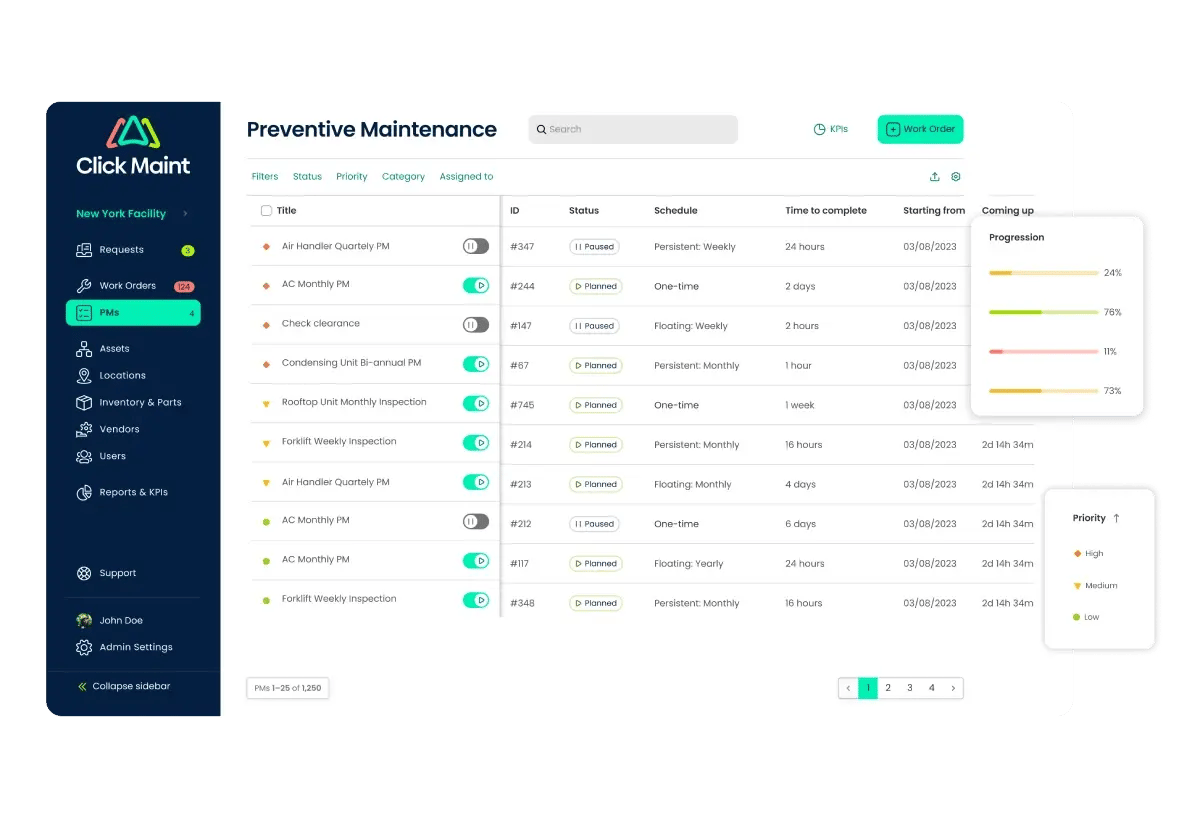

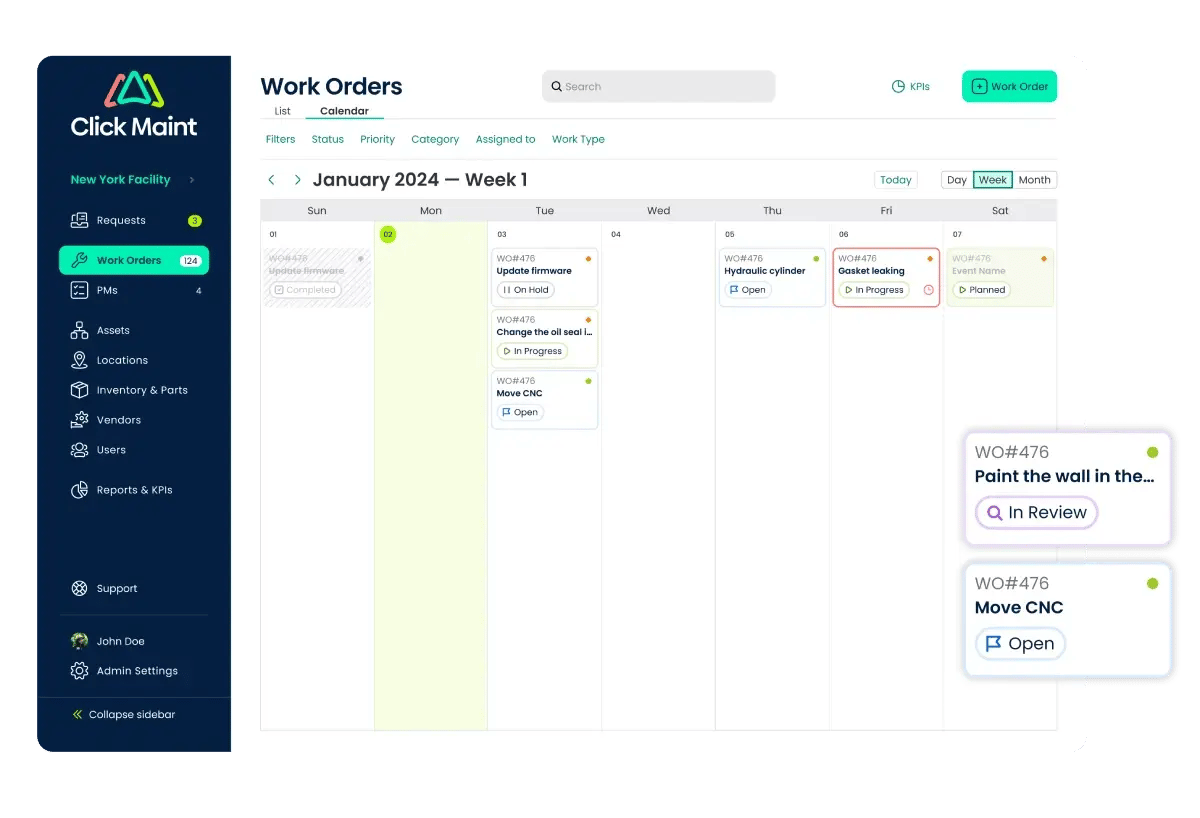

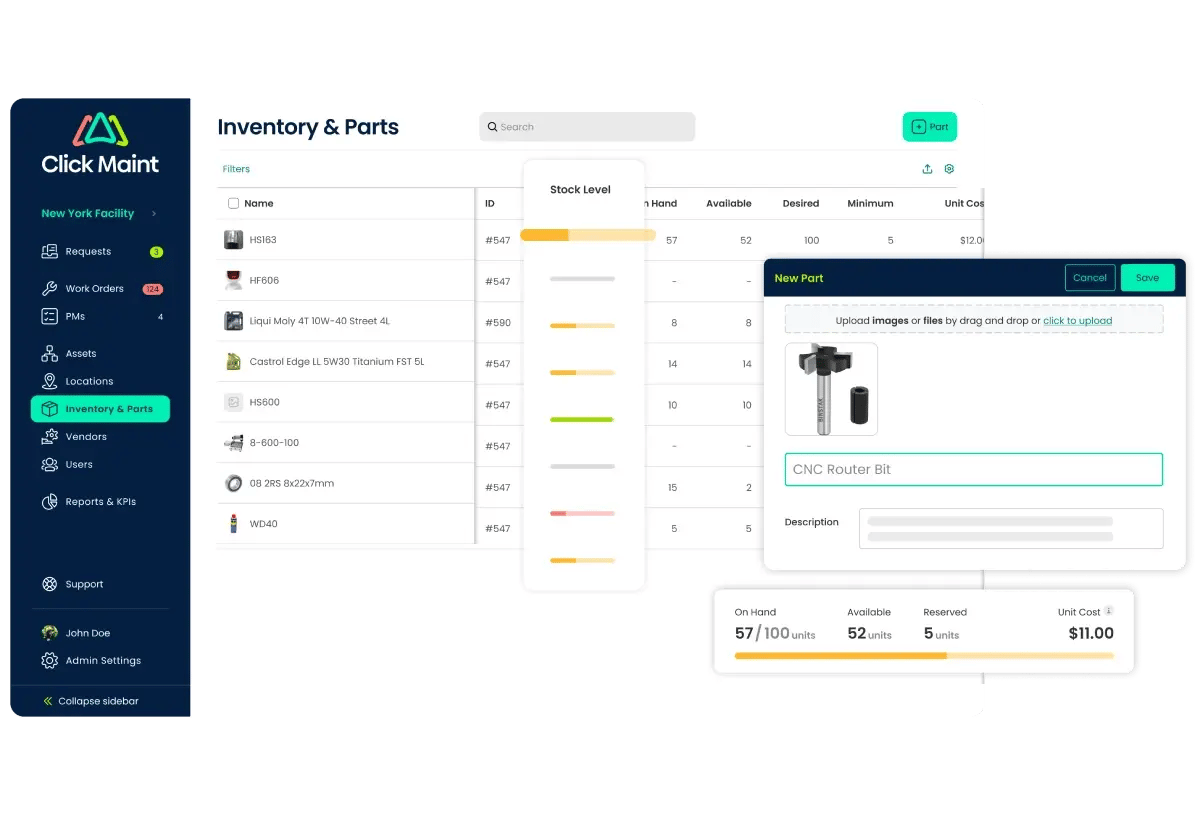

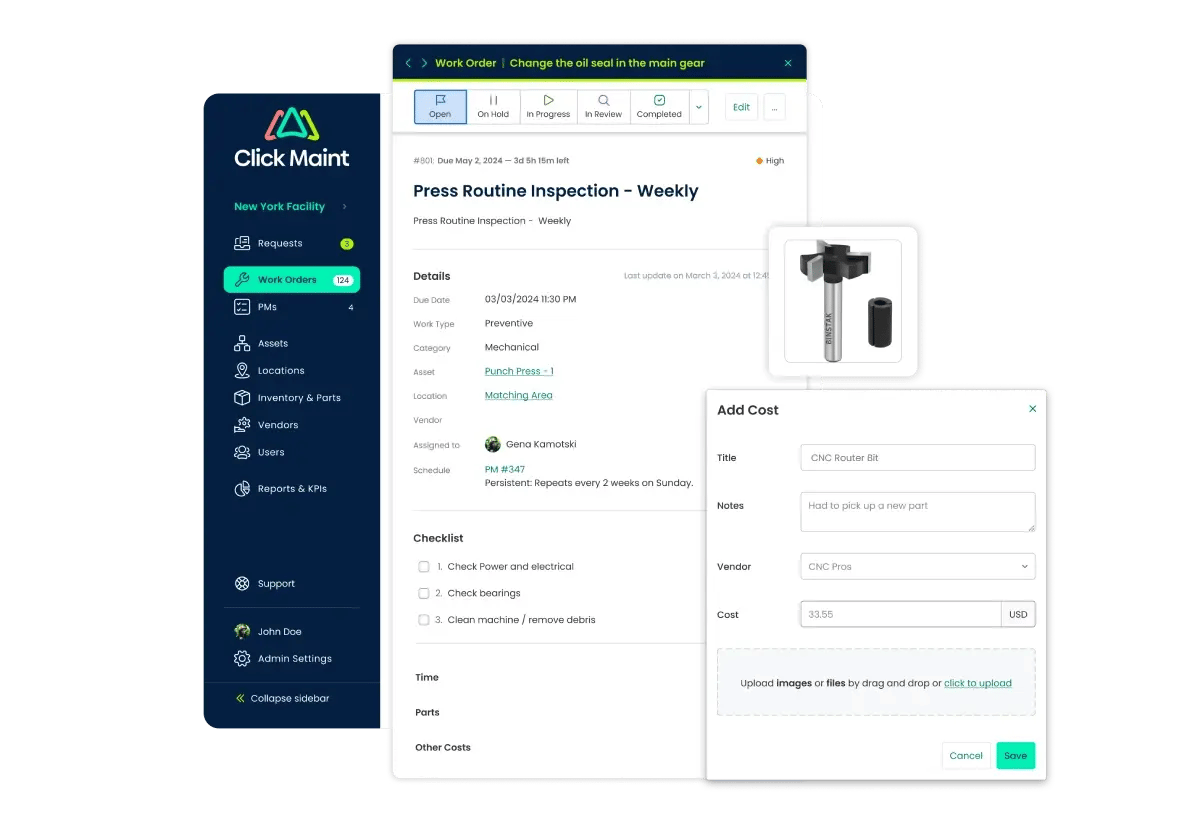

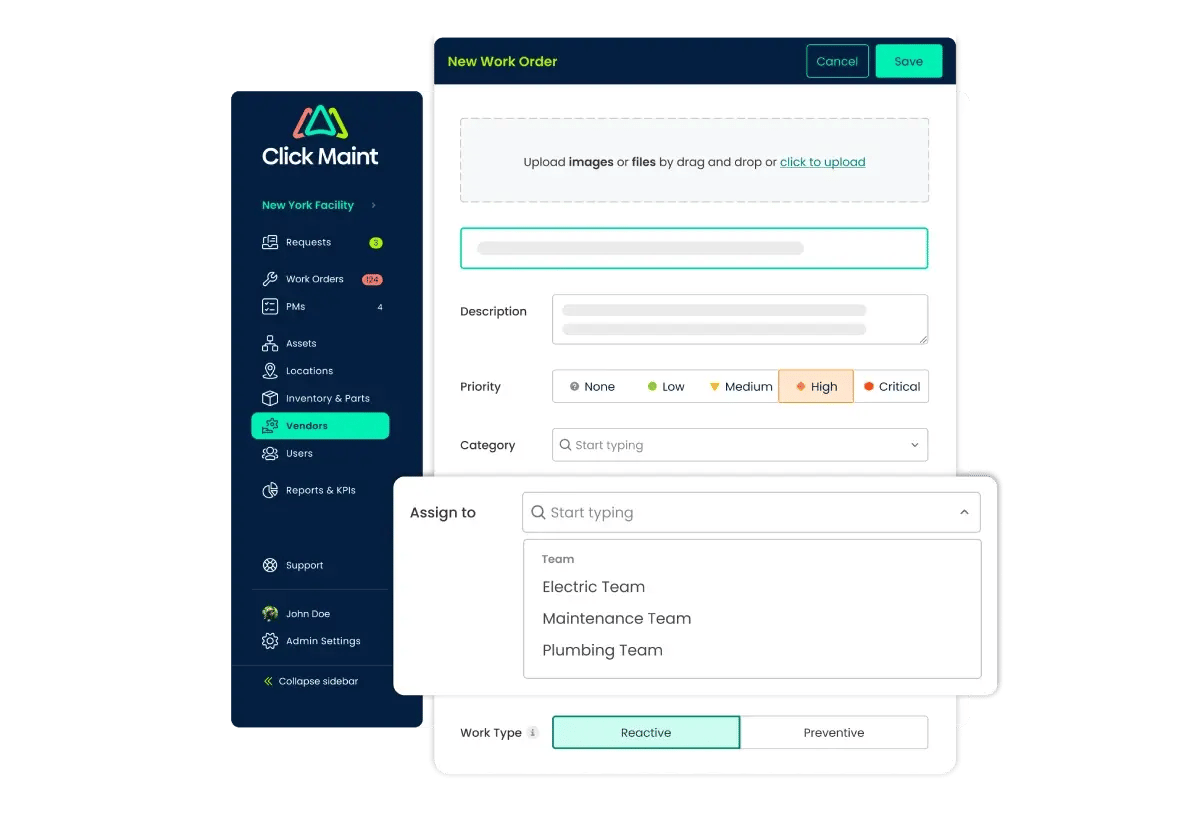

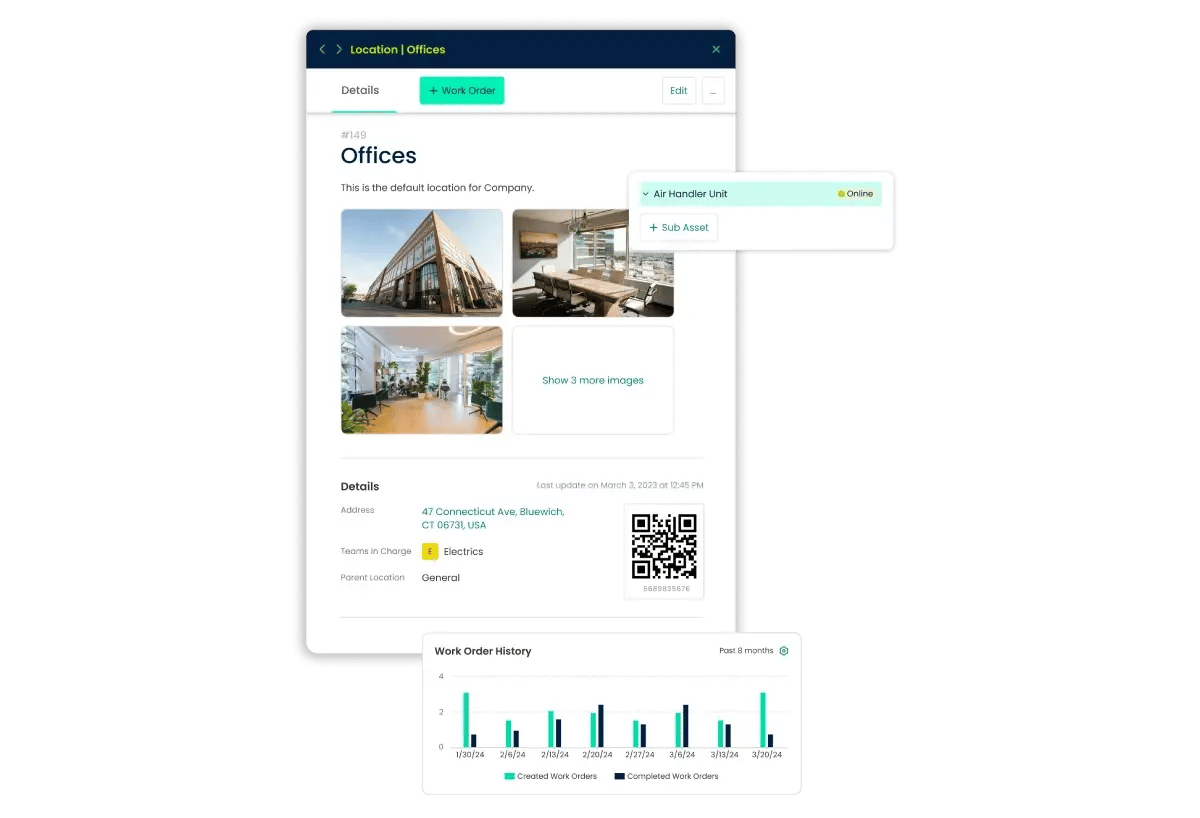

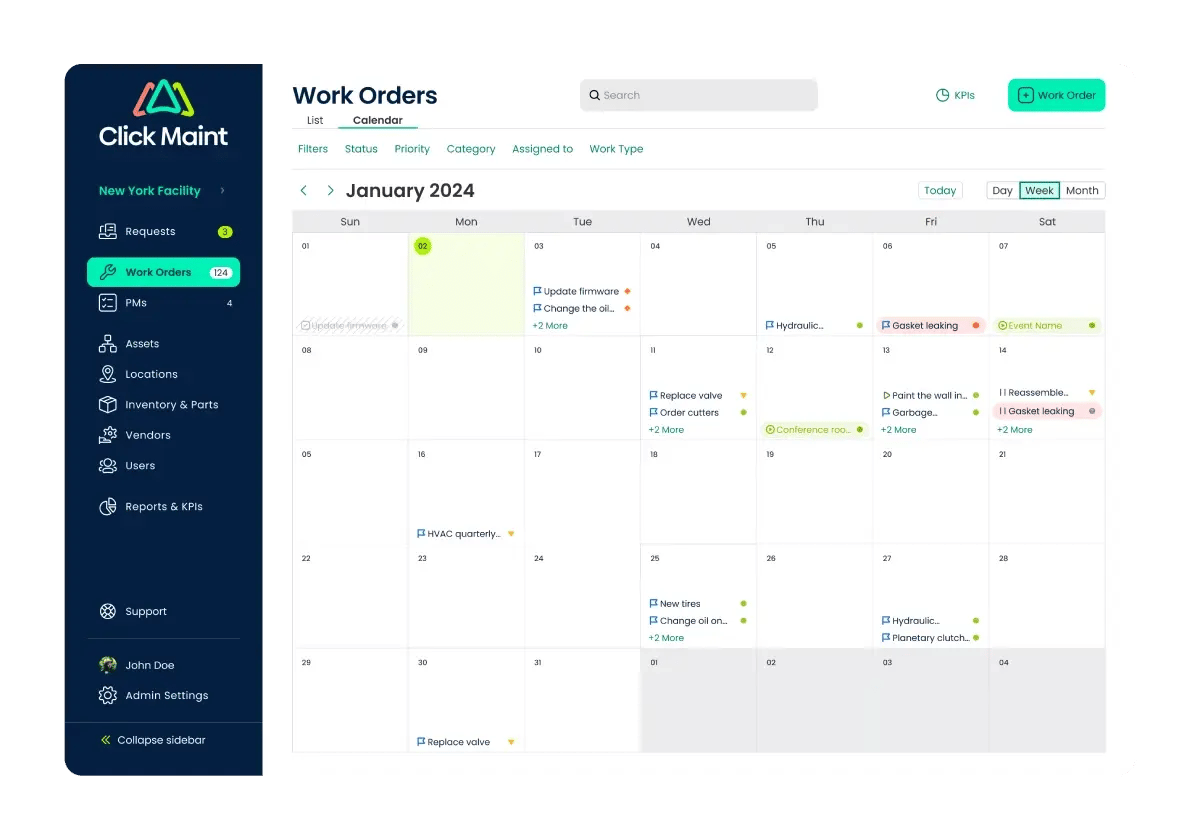

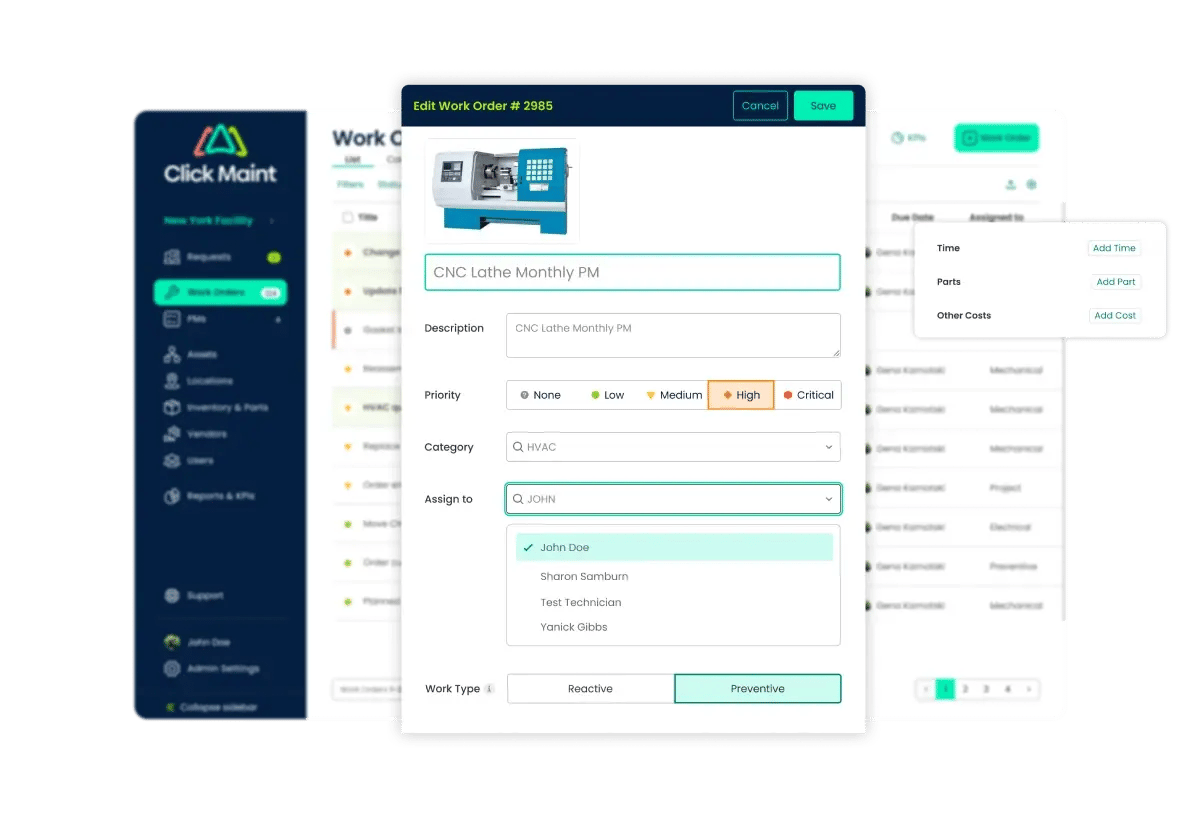

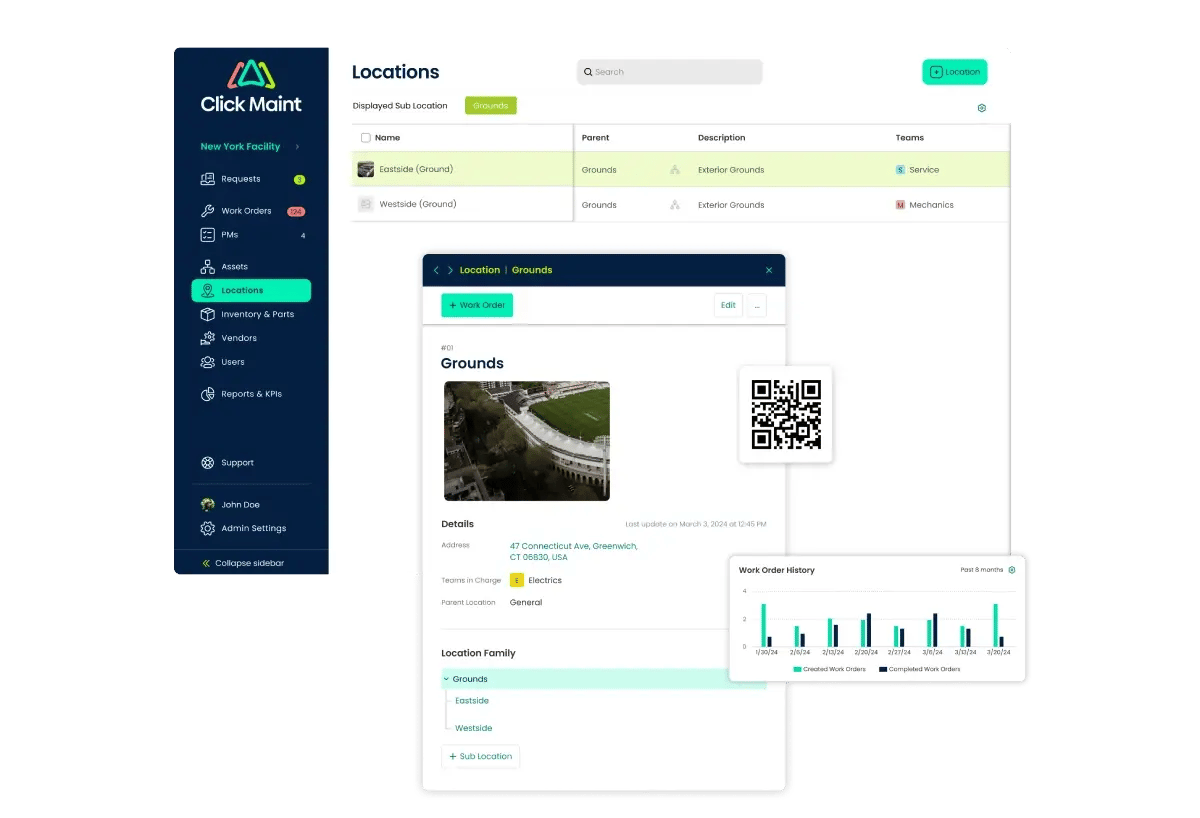

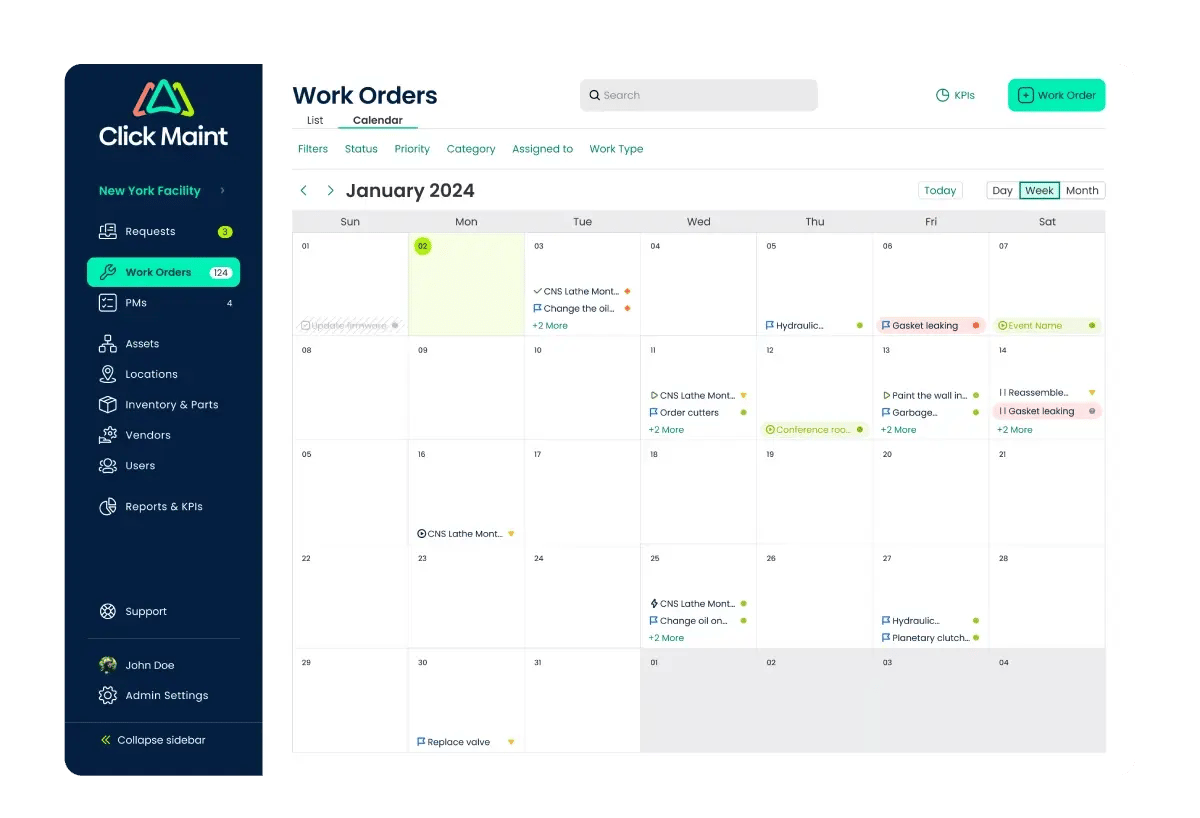

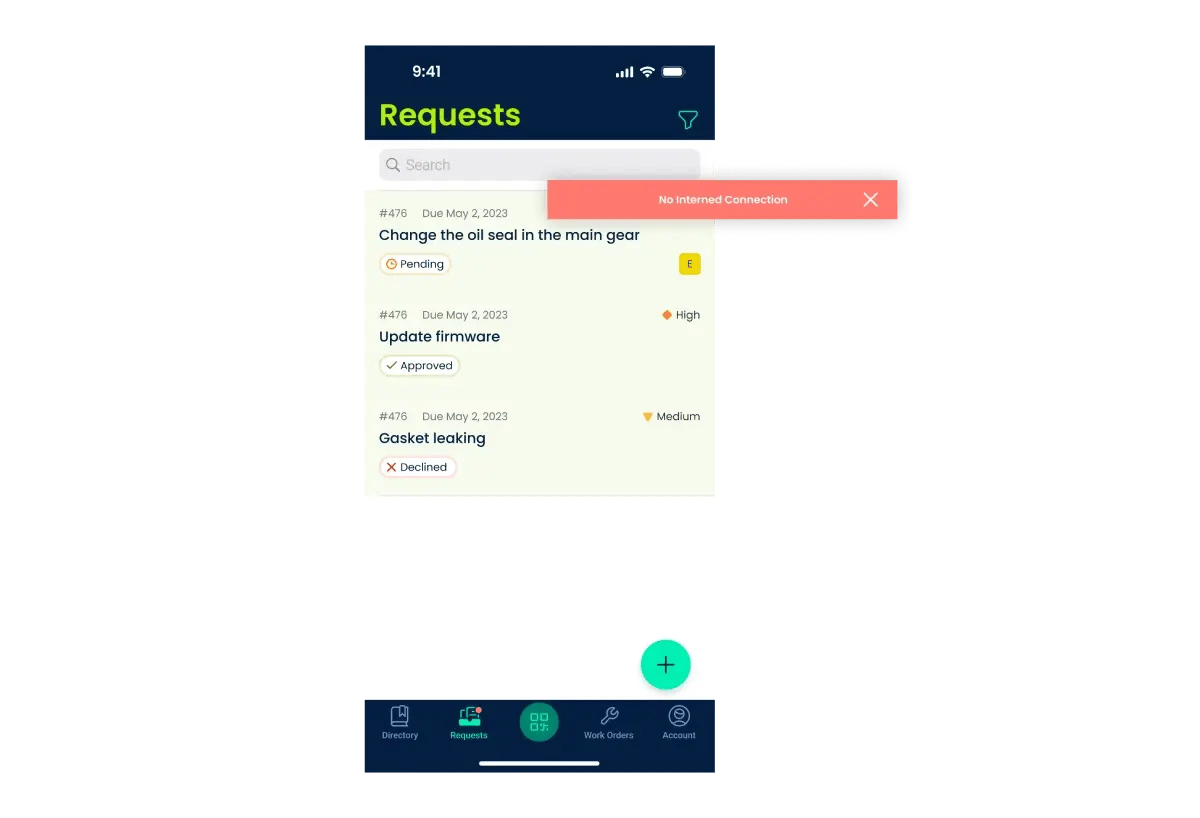

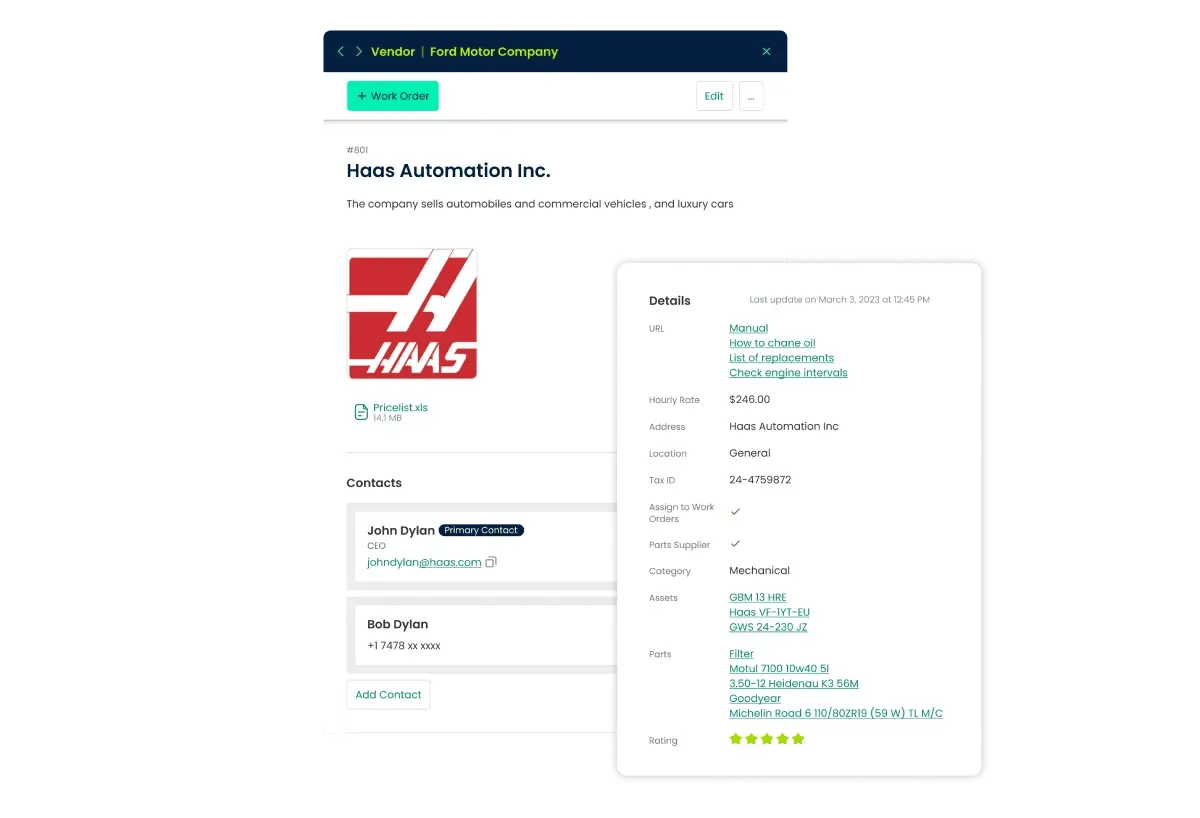

A CMMS provides a dedicated inventory management functionality or module within the system that allows maintenance teams to effectively manage and track inventory for maintenance activities, ensuring the availability of spare parts, reducing equipment downtime, and optimizing maintenance processes. Parts and other inventory items are used on corrective maintenance and preventive maintenance work orders. The CMMS’s inventory management module makes it easy for users to identify parts used for specific assets and work orders, know how many parts are available, which suppliers to order from, and to process orders.

What are the key features to look for in Inventory Management Software?

Key features to consider include real-time inventory tracking, automated stock replenishment, barcode / QR code generation and reading, supplier management, demand planning, and reporting & analytics capabilities. Additionally, integration capabilities with existing systems, user-friendly interface, mobile accessibility, and security measures are important factors to evaluate.

How does Inventory Management Software help in cost reduction?

The software helps in cost reduction by minimizing stock outages and overstocking, optimizing inventory levels, streamlining procurement processes, and preventing excess or obsolete inventory. By maintaining optimal inventory levels, businesses can reduce carrying costs, minimize waste from degraded inventory, avoid expensive costs of rush orders, and reduce costly equipment downtime.

Can Inventory Management Software help with demand forecasting?

Yes, some more robust inventory management solutions offer demand forecasting capabilities. These tools use historical data, trend analysis, and statistical algorithms to predict future demand, allowing businesses to plan their inventory levels and purchasing activities more accurately, reducing stockouts and improving customer satisfaction.

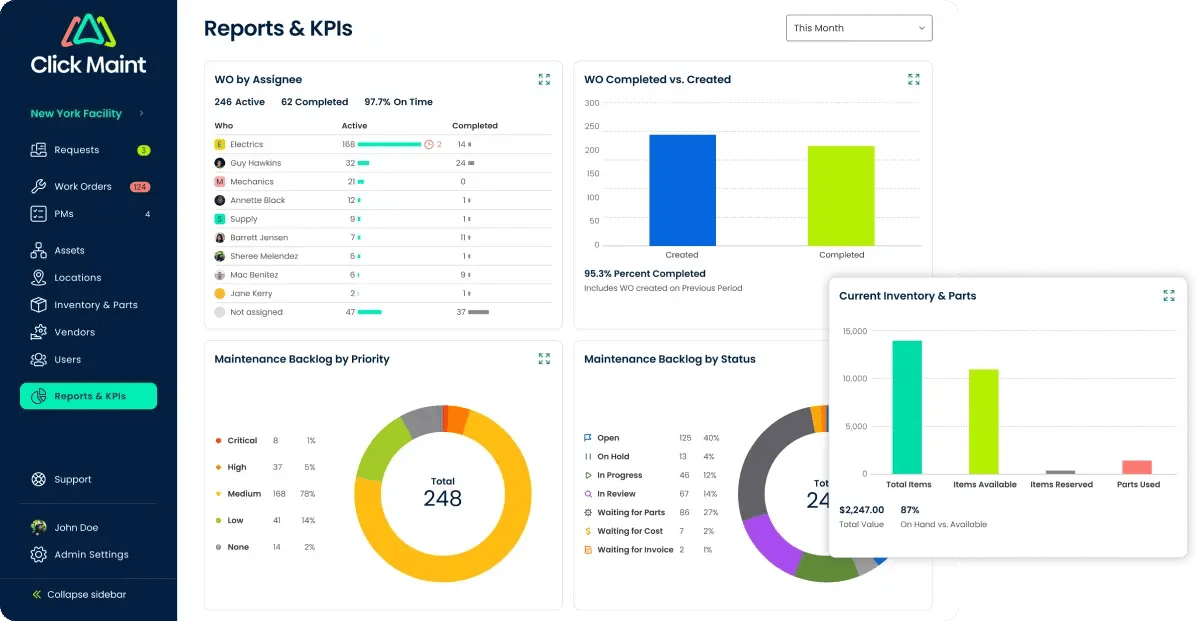

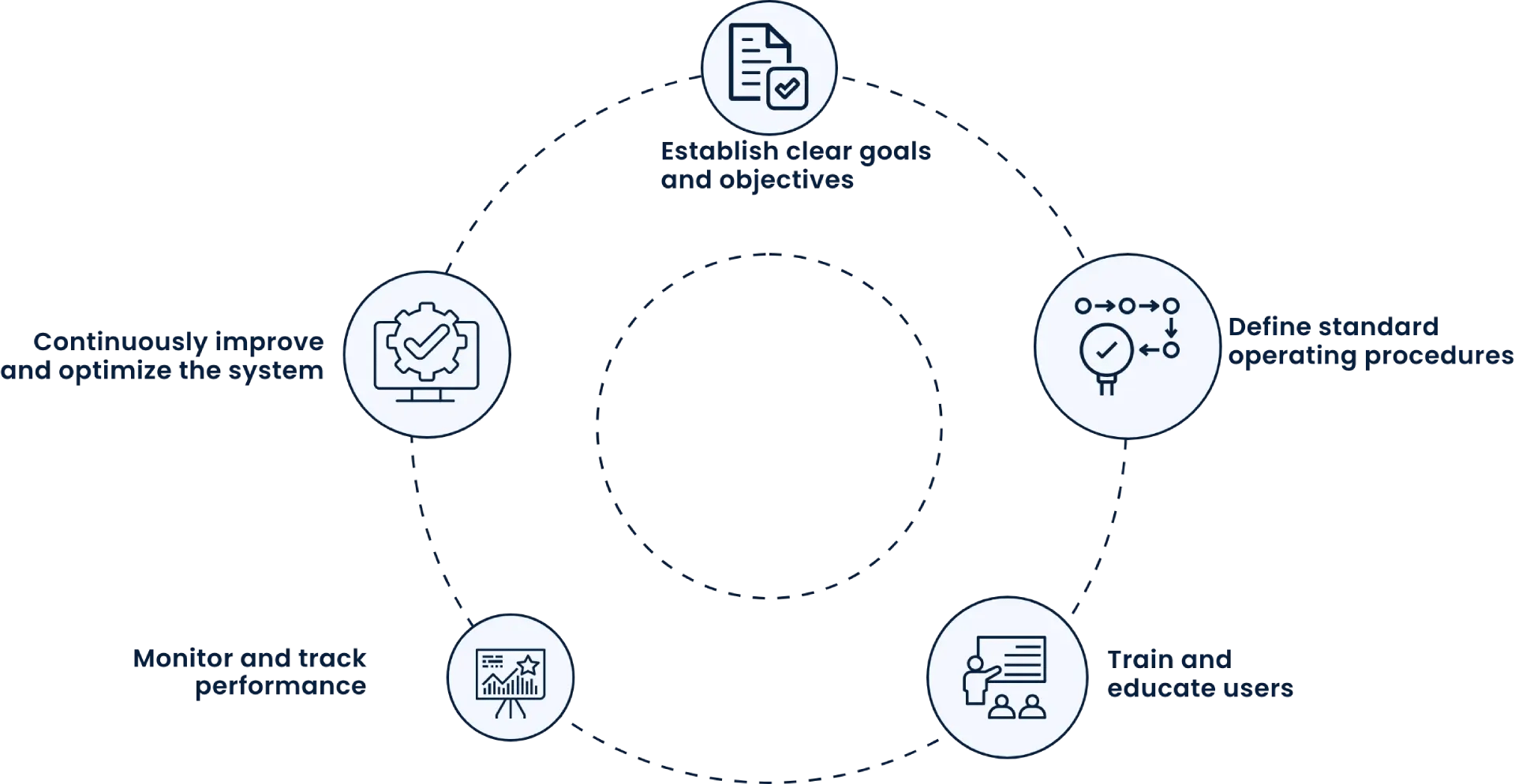

How can I measure the success and effectiveness of Inventory Management Software implementation?

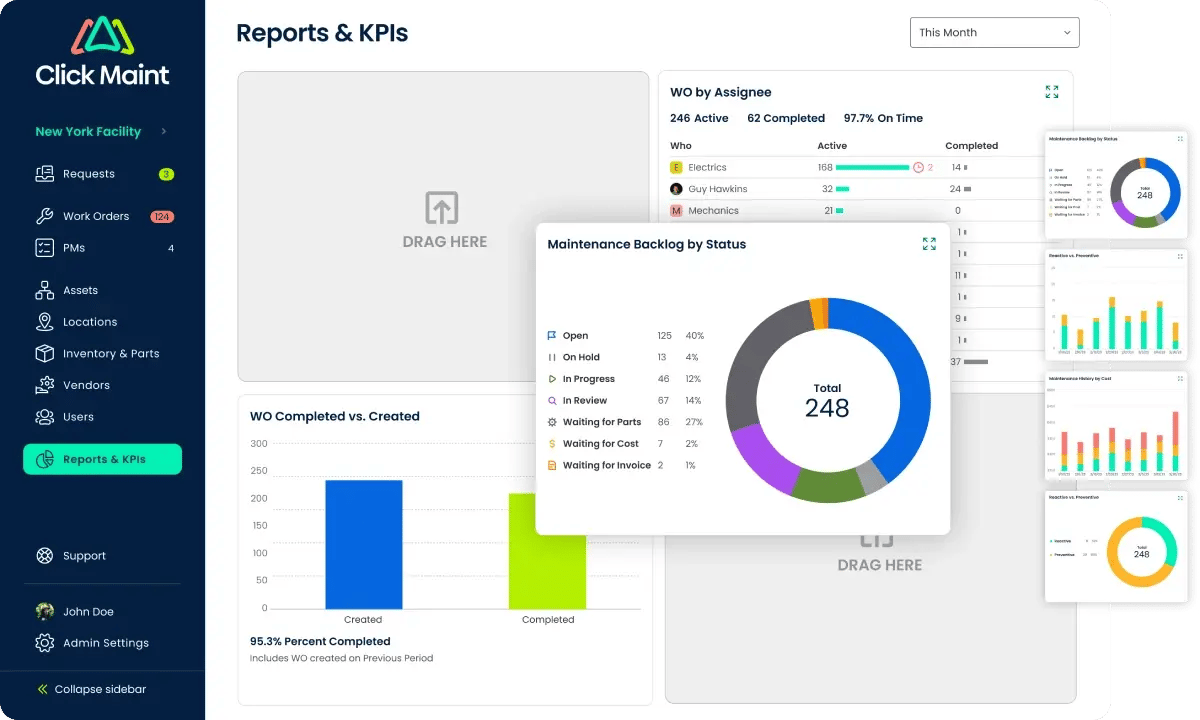

Success can be measured by monitoring key performance indicators (KPIs) such as stock accuracy, turnover rate, order fulfillment rate, and inventory carrying costs. By tracking these metrics before and after implementing the software, businesses can assess the impact, identify areas of improvement, and make data-driven decisions to optimize inventory management processes.

Can Inventory Management Software be customized to suit specific business needs?

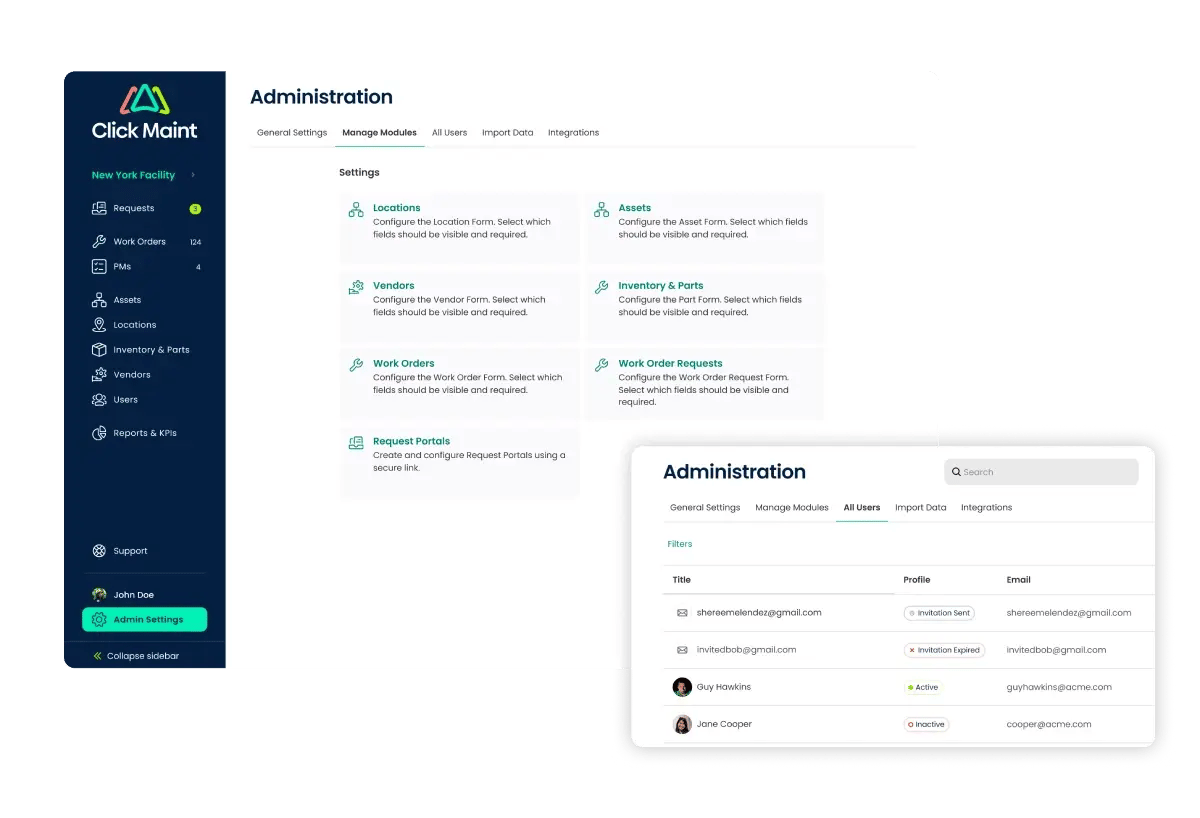

Yes, many inventory management solutions offer customization options to align with specific business requirements. This may include configuring workflows, data fields, reports, and integrations with other systems. It is important to communicate your specific needs with the software vendor and ensure that customization options are available to tailor the software to your unique business processes.

Why investing in Inventory Management Software could be a game-changer for your business?

Investing in advanced inventory management software not only streamlines your operations but also directly impacts your bottom line. Businesses often experience a significant reduction in operational costs due to increased efficiency and accuracy in inventory handling. For instance, automated stock replenishment and demand forecasting features help eliminate the guesswork associated with ordering, ensuring that you maintain optimal stock levels without overspending. Furthermore, a robust software solution can provide analytics and insights into inventory trends, enabling businesses to identify slow-moving items and make informed purchasing decisions. This level of insight not only supports better cash flow management but also fosters stronger supplier relationships through timely orders.

How does an Inventory Management Software enhance customer satisfaction?

The benefits of inventory management software extend beyond internal operations; they significantly enhance customer satisfaction. With accurate inventory tracking and demand forecasting, businesses can ensure that popular products are readily available, reducing lead times for customers. By preventing stockouts, you foster a reputation for reliability, encouraging repeat business and customer loyalty. Additionally, improved order fulfillment processes mean that customers receive their products quickly and accurately, further enhancing their experience with your brand. In a competitive marketplace, where customer expectations are continually evolving, having a dependable inventory management system is vital to maintaining a competitive edge.