Develop a preventive maintenance plan

This involves creating a comprehensive list of equipment that requires preventive maintenance, outlining the maintenance tasks, and determining the frequency of maintenance.

Maximize Equipment Uptime, Minimize Costs

MadgeTech

Starsky

NECC

The Pacific Club

Steer Medical

Lake Elsinore Strom

Grupo Herroro

The Oswego Hotel

MPI Label Systems

Strom Chasers

US Sport Planes

CMOA

Classical Academy

Turnstone

KFC

Orchard

Taco Bell

Jersey Mike’s

PROFESSIONAL PLAN

$ 42 USD

PER USER PER MONTH

$ 35 USD

PER USER PER MONTH

By enabling businesses to conduct regular maintenance, the software allows businesses to schedule and track maintenance tasks, reducing wear and tear on parts, preventing breakdowns, and catching small problems before they turn into larger ones.

Equipment downtime can be costly in terms of lost production, revenue, and customer satisfaction. Preventive maintenance software ensures that equipment is properly maintained, reducing the risk of unexpected breakdowns and downtime.

Properly maintained equipment is less likely to cause accidents and injuries in the workplace. Preventive maintenance software can help identify potential safety hazards and schedule maintenance tasks to address them before they become a problem.

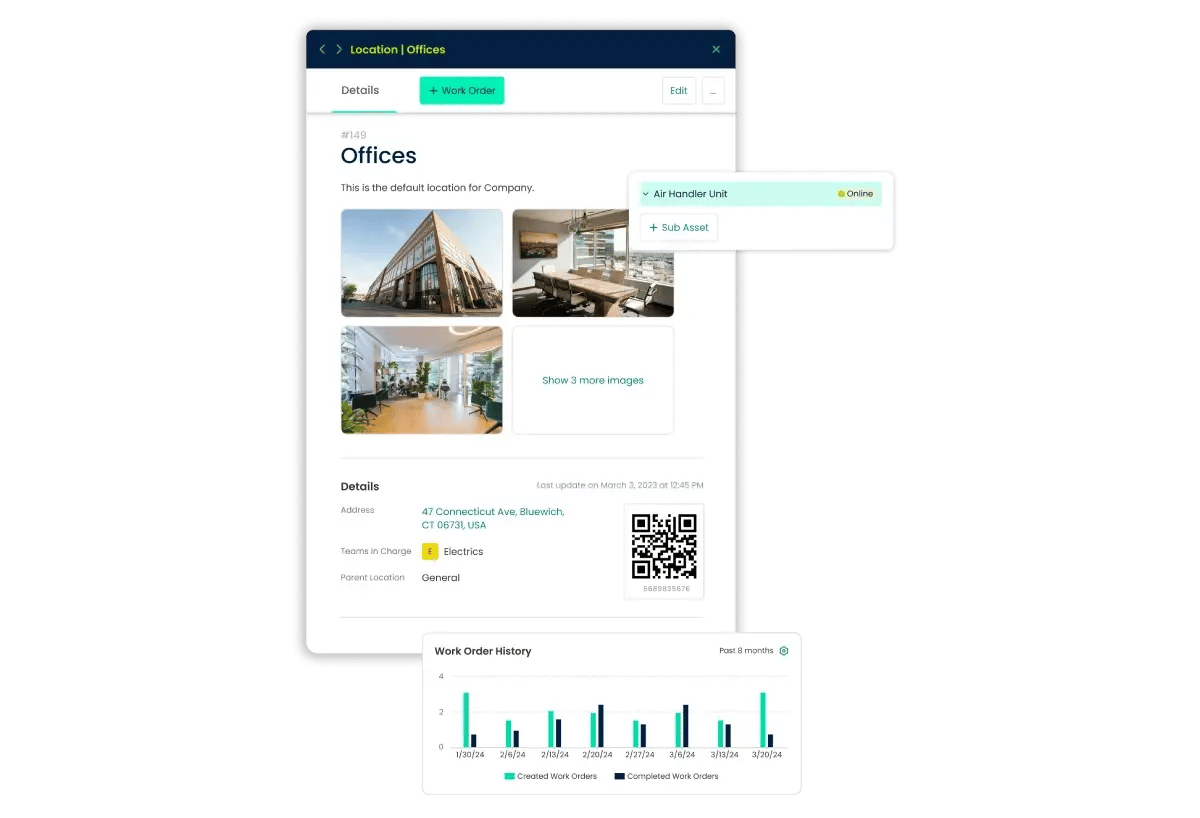

Preventative maintenance software allows businesses to keep track of all their equipment, including location, maintenance history, and current status. This information can be used to make informed decisions about equipment replacement and upgrades.

By having all preventive maintenance data stored in a single cloud-based platform, accessible from anywhere and by anyone, teams can collaborate more efficiently without having to rely on excel or other offline formats. This enables better communication, coordination, and decision-making, leading to improved asset performance and reduced maintenance costs.

Businesses can gather real-time data on their equipment, including performance, usage patterns, and maintenance history. This data can be used to generate analytics that provide insights into the health of the equipment and identify areas for improvement.

No Credit Card needed.

Instant access to all features & modules with an optional live walk-through with a Click Maint expert

In this 30-minute demo, see firsthand how our easy CMMS can streamline your operations, enhance productivity, and reduce downtime.

For Optimal Maintenance Efficiency

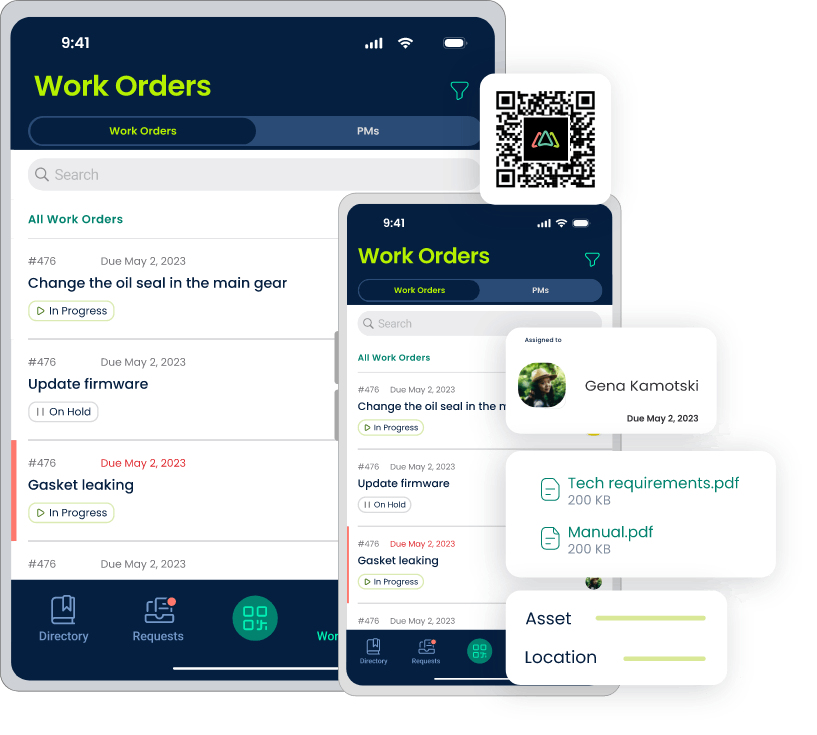

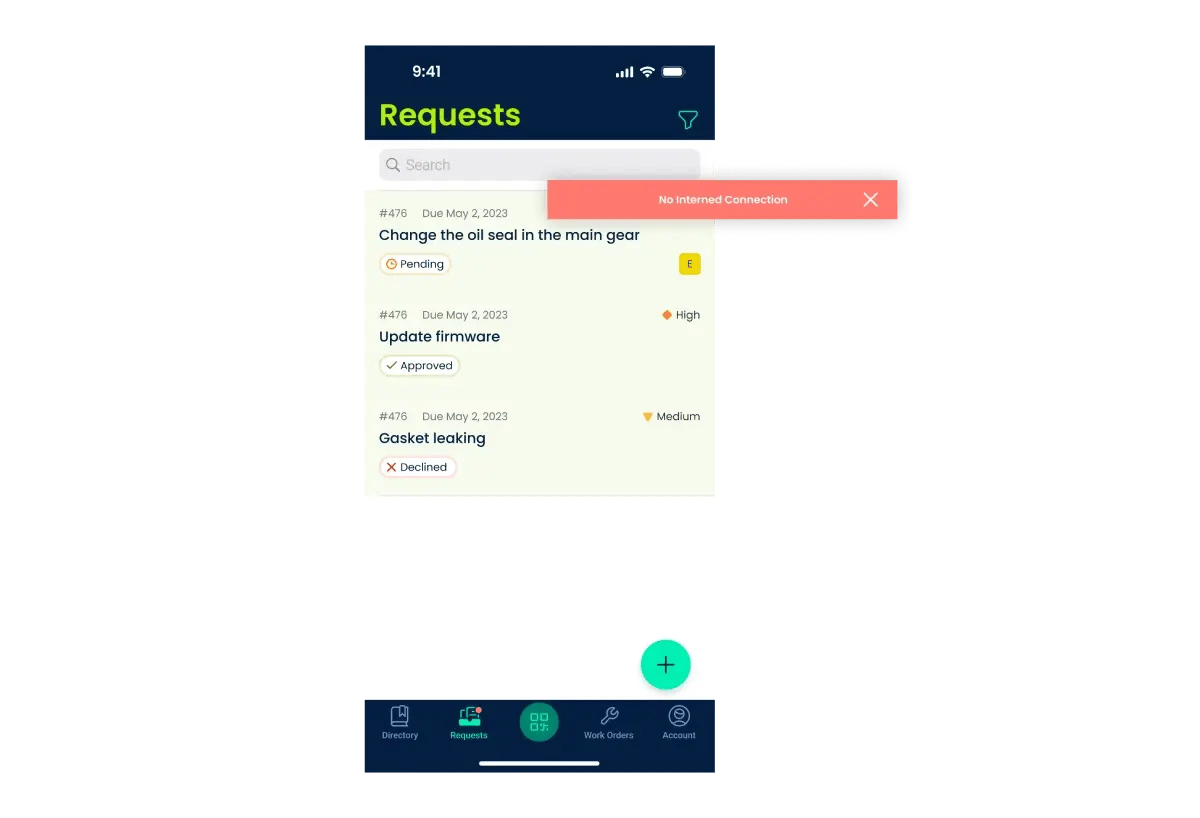

For Preventive Maintenance Management on-the-go

Access the CMMS from anywhere, using mobile devices such as smartphones or tablets.

Scan barcodes on assets, parts, and inventory using a mobile device's camera.

Use voice commands to perform tasks, such as creating work orders or updating asset information.

Receive real-time updates on work order status, asset history, and inventory levels.

Communicate and collaborate with team members and external partners, such as contractors or suppliers.

Receive alerts and notifications for upcoming maintenance tasks, low inventory levels, or other important events.

Attach images and videos to work orders and asset records, providing additional context for technicians and managers.

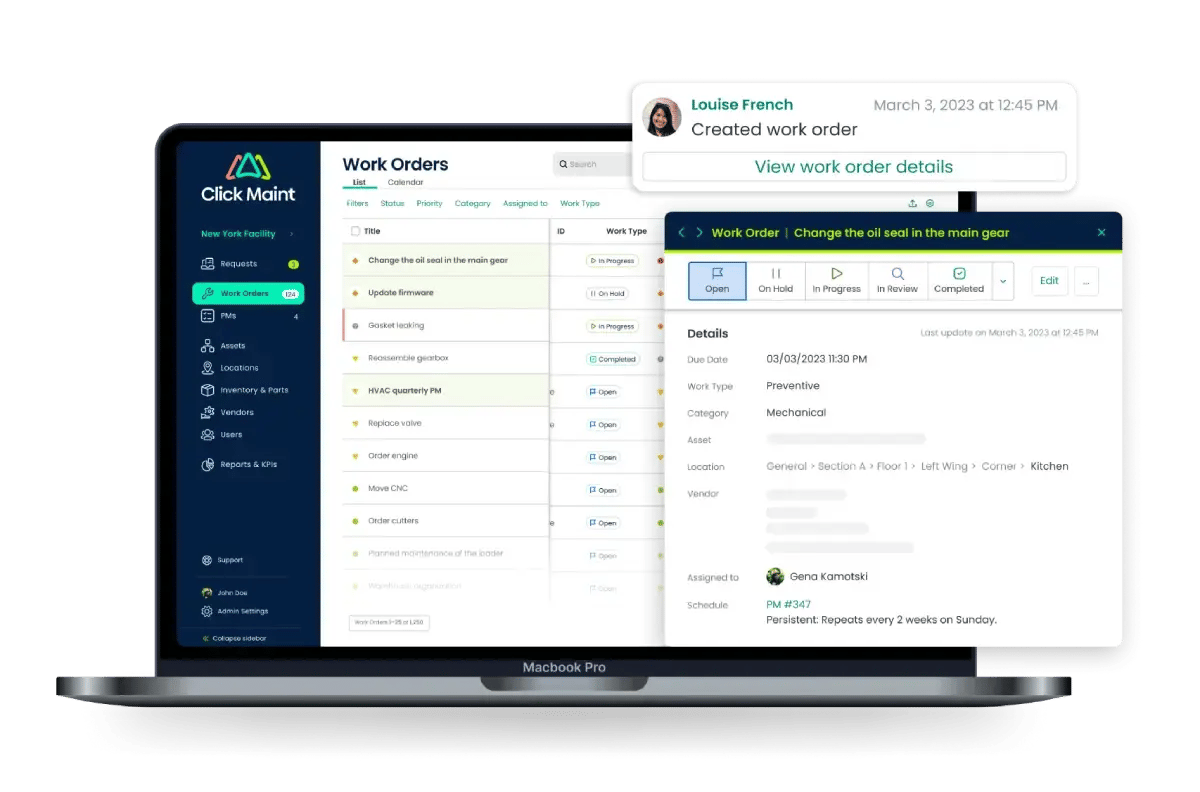

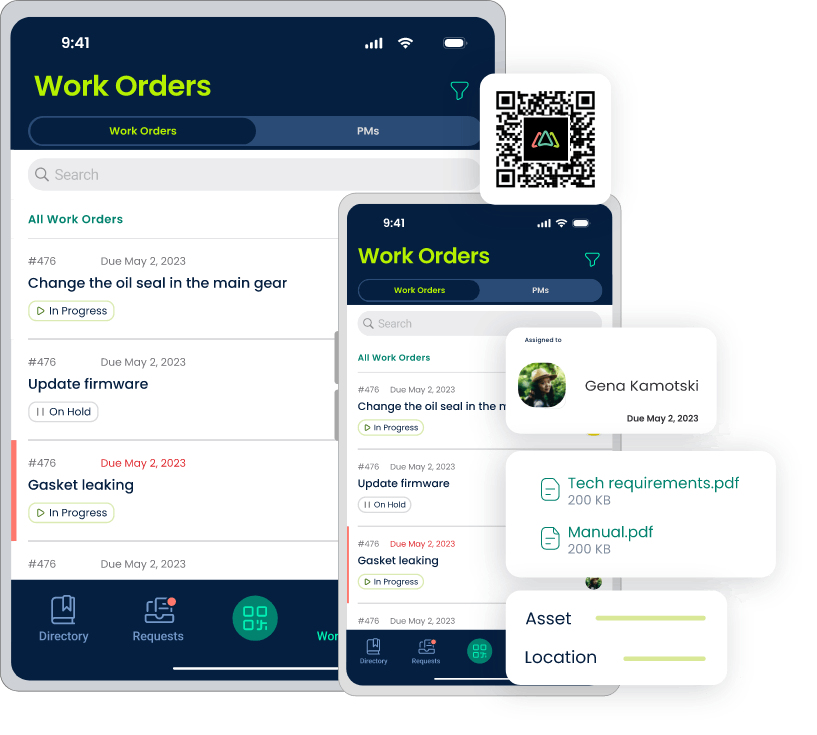

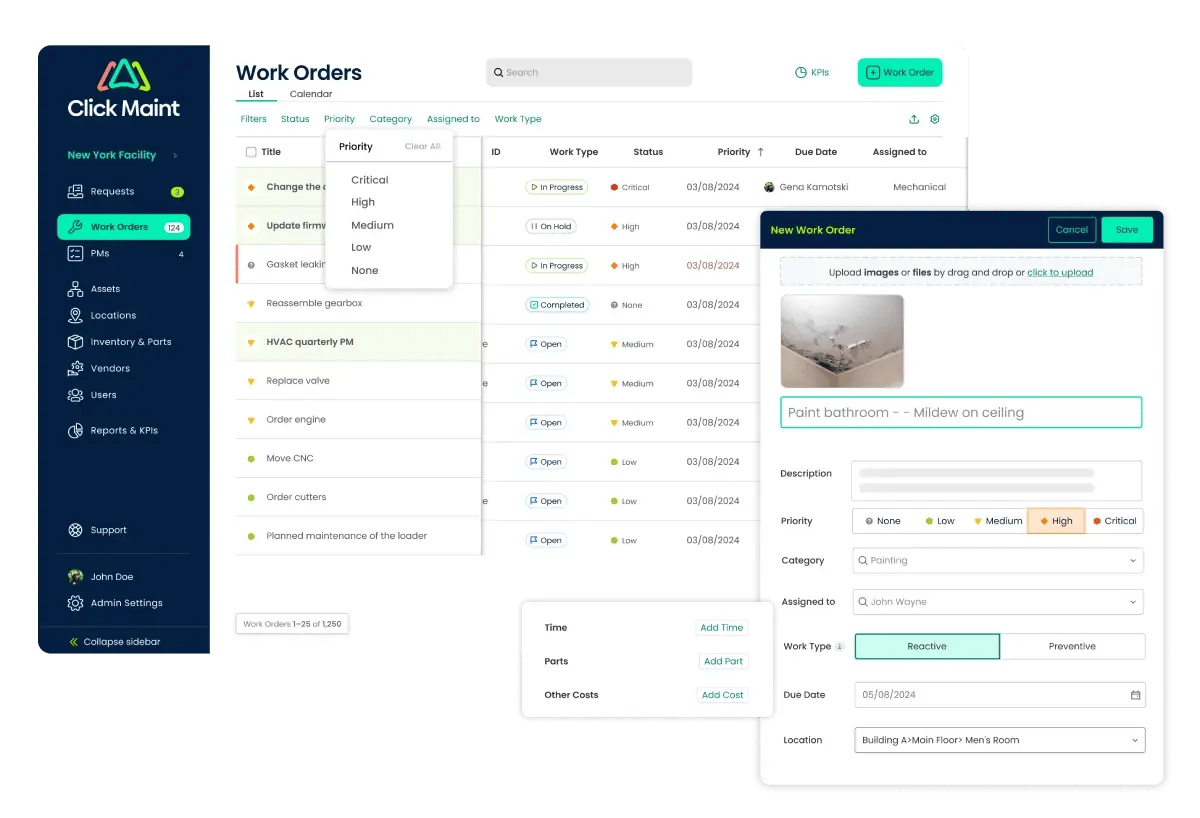

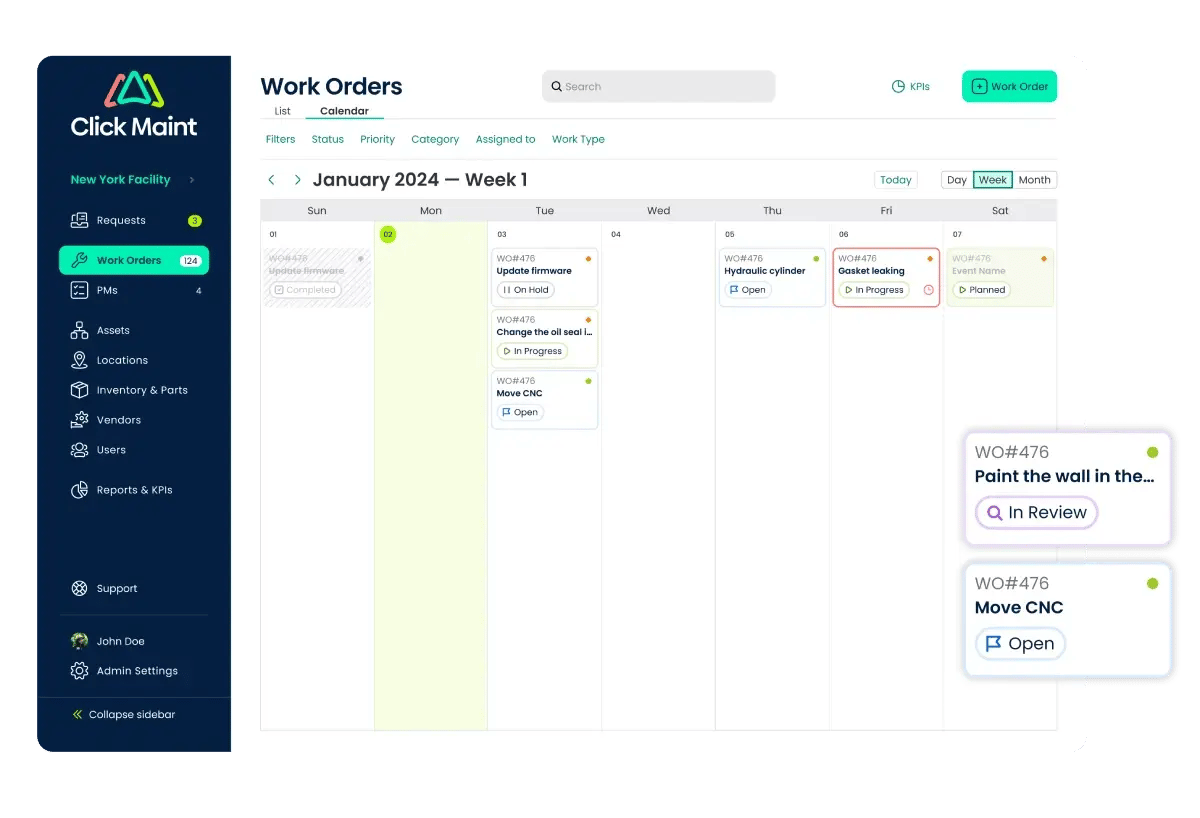

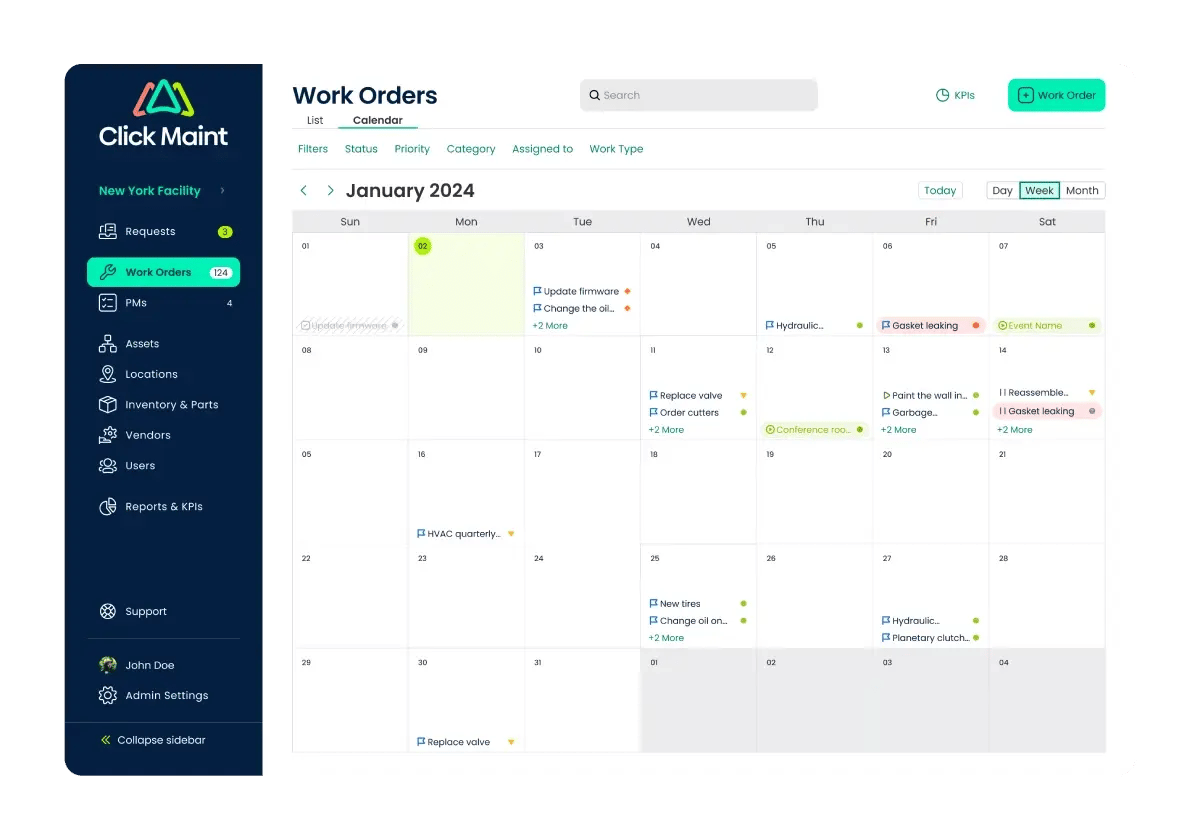

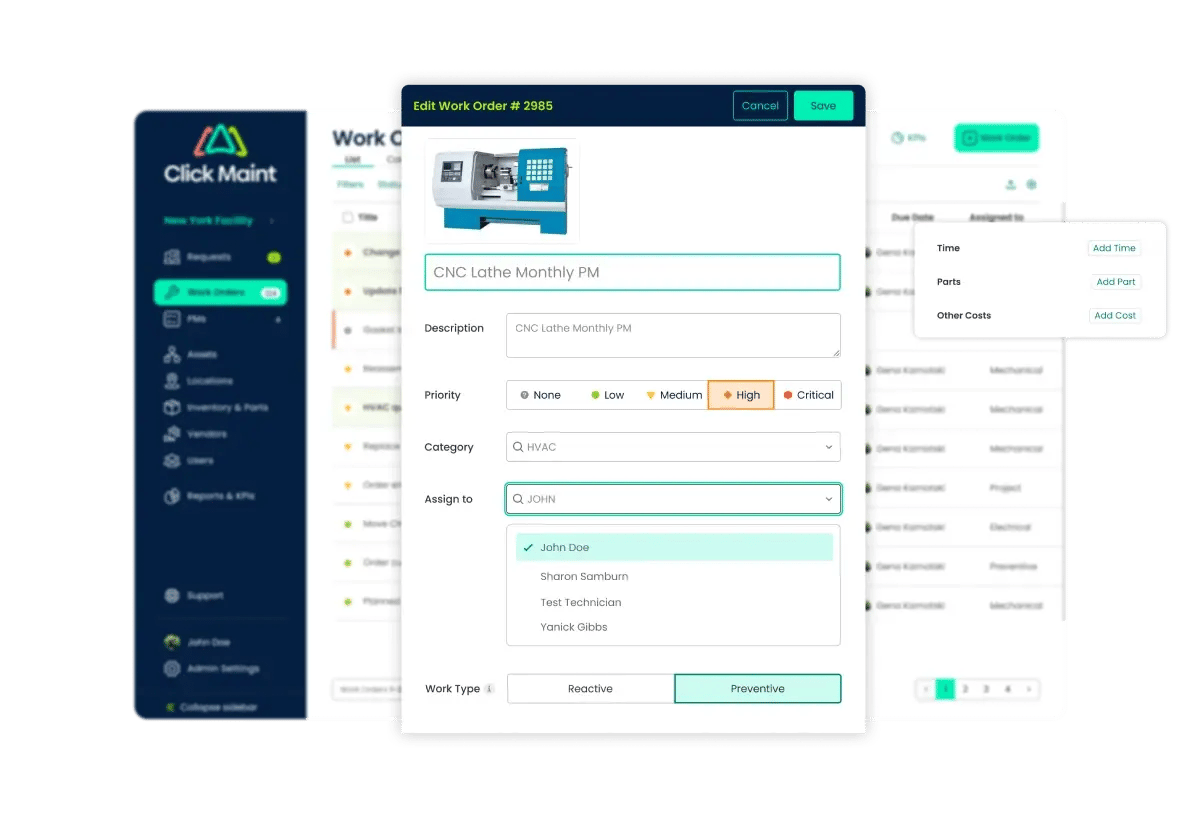

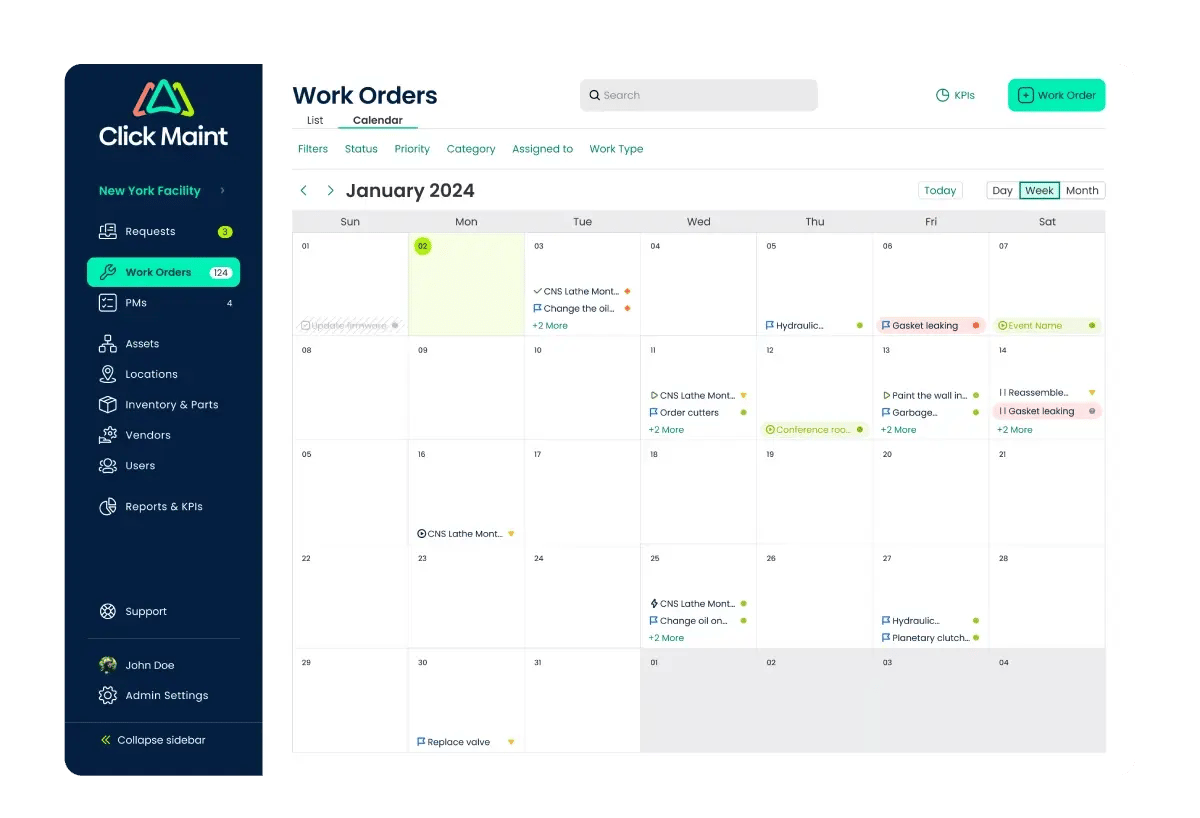

Create, assign, and track work orders, allowing you to monitor progress and ensure fast response and completion times. (Add filters)

Create, assign, and track work orders, allowing you to monitor progress and ensure fast response and completion times. (Add filters)

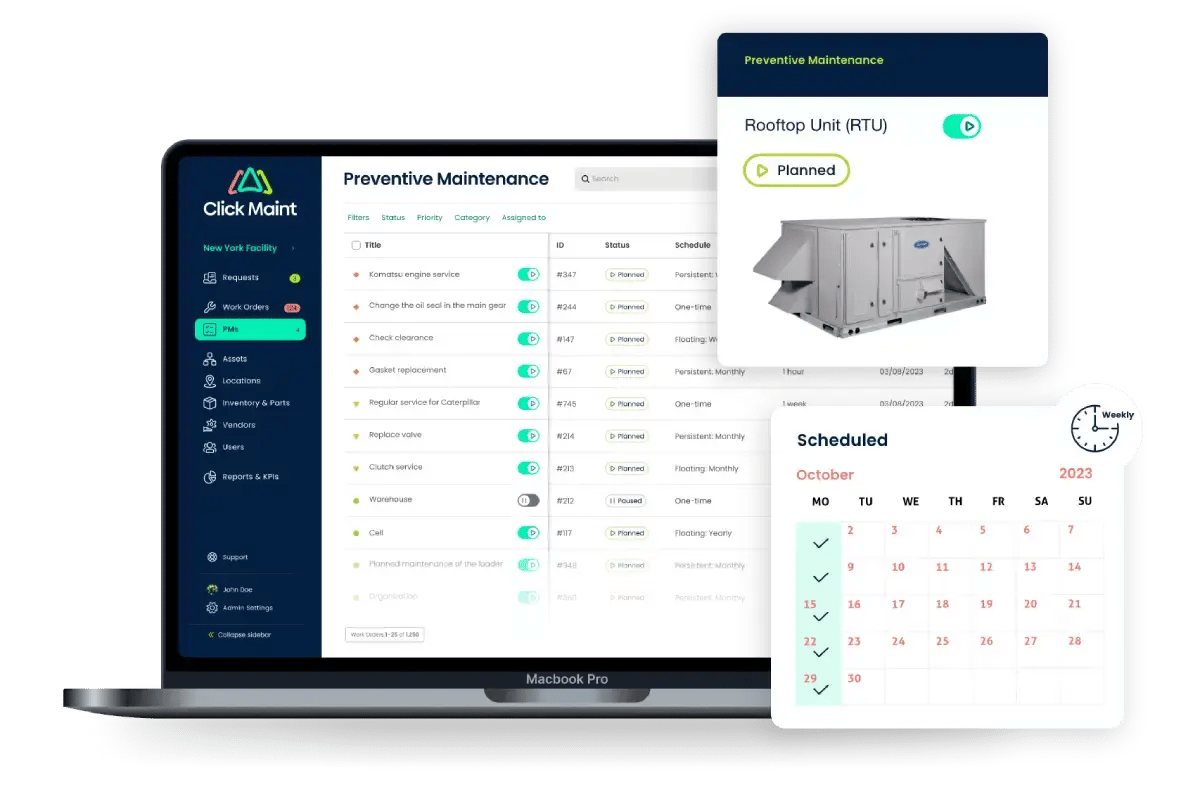

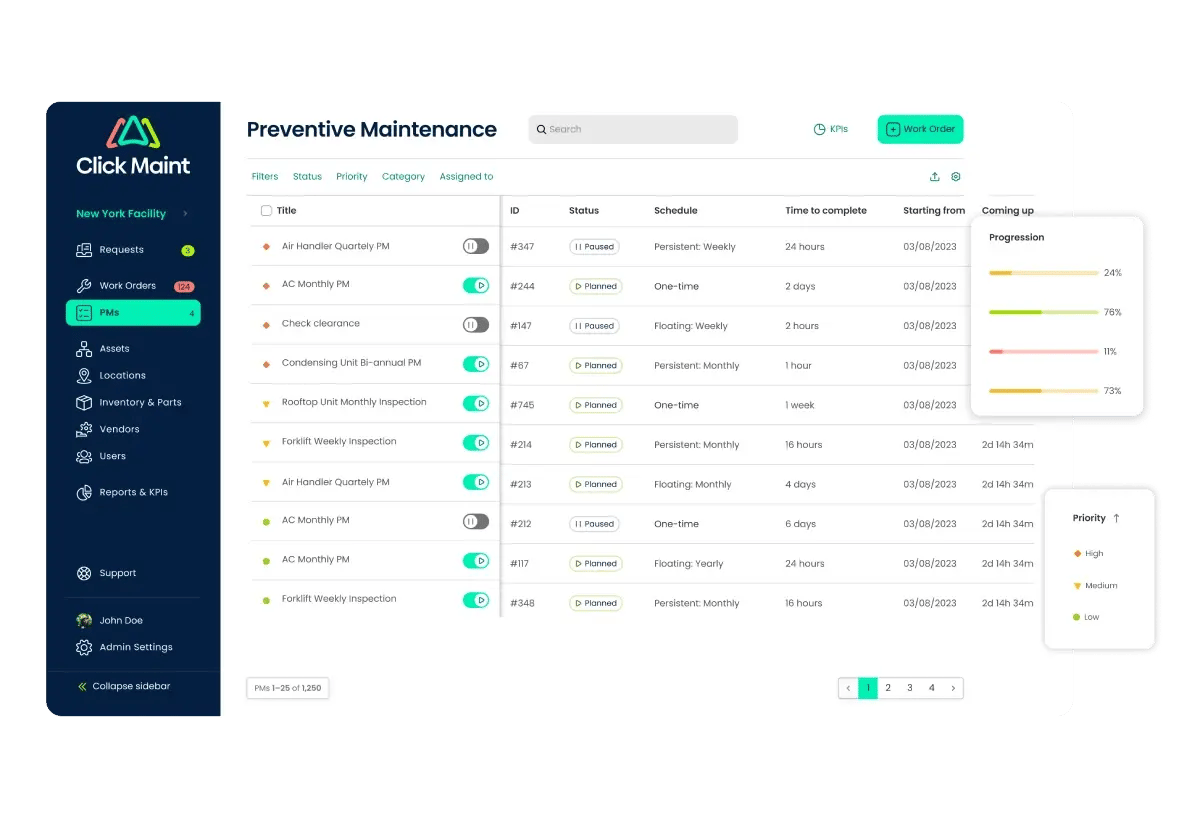

Schedule routine maintenance and inspections to prevent equipment failures and unplanned downtime and extend the lifespan of assets.

Schedule routine maintenance and inspections to prevent equipment failures and unplanned downtime and extend the lifespan of assets.

Plan and organize maintenance tasks, including preventive maintenance and inspections to reduce equipment downtime and improve efficiency, extend equipment life, and reduce repair costs.

Plan and organize maintenance tasks, including preventive maintenance and inspections to reduce equipment downtime and improve efficiency, extend equipment life, and reduce repair costs.

Equip maintenance teams with an easy-to-use mobile app that empowers users to manage work orders and tasks on the go. Users can scan QR codes, upload images, use voice to text, and more.

Equip maintenance teams with an easy-to-use mobile app that empowers users to manage work orders and tasks on the go. Users can scan QR codes, upload images, use voice to text, and more.

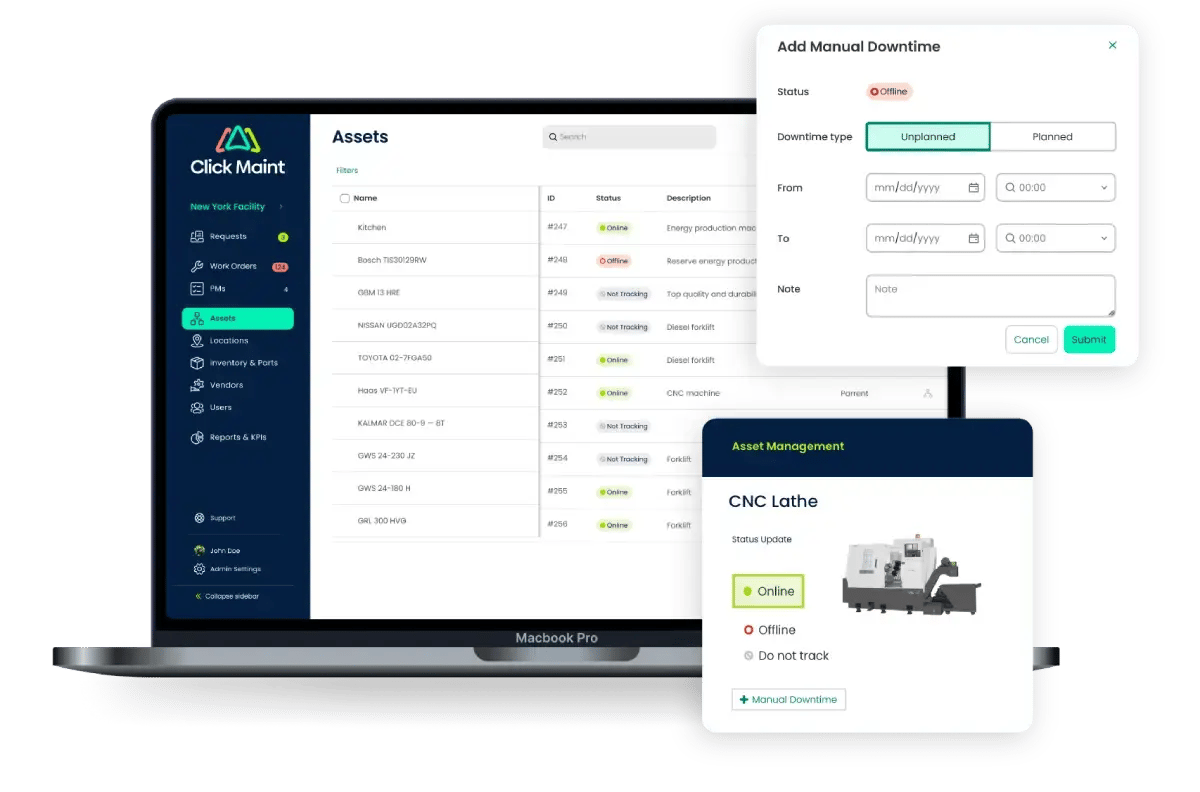

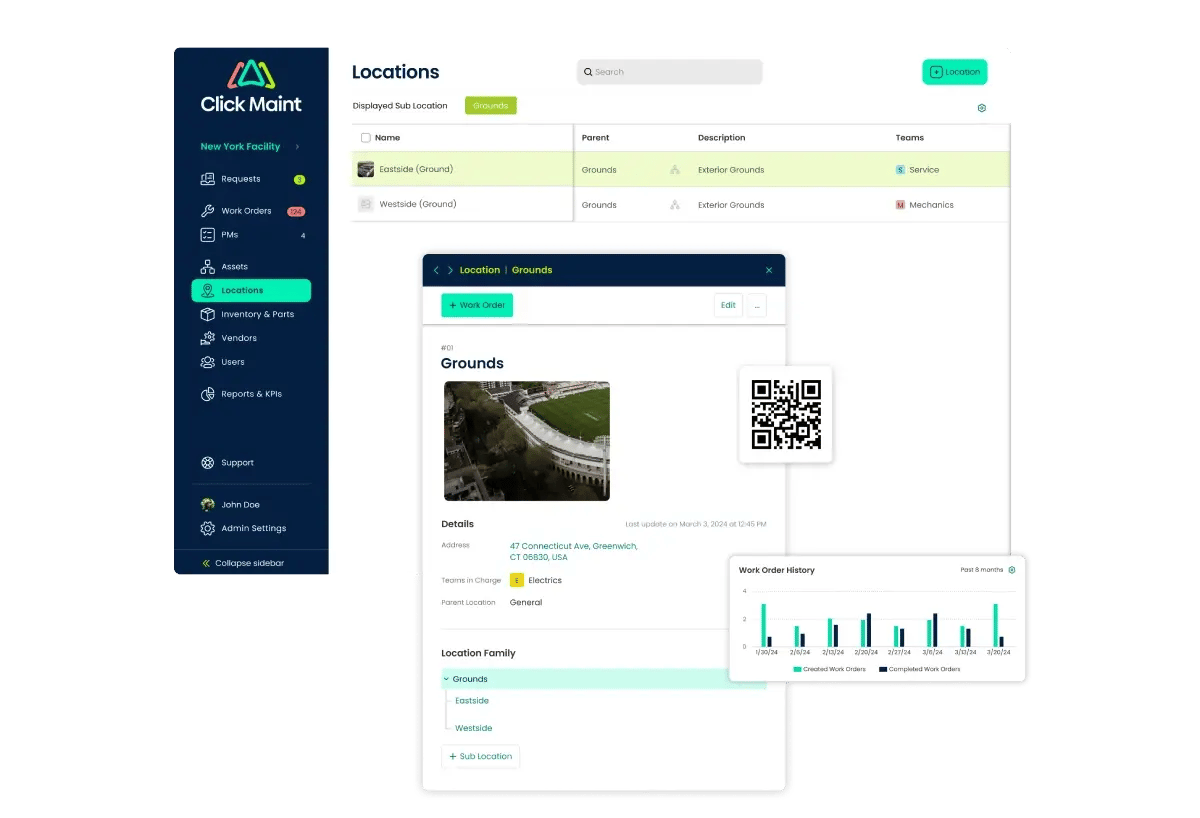

Keep track of assets, including their location, condition, and maintenance history, to streamline maintenance planning and improve asset longevity.

Keep track of assets, including their location, condition, and maintenance history, to streamline maintenance planning and improve asset longevity.

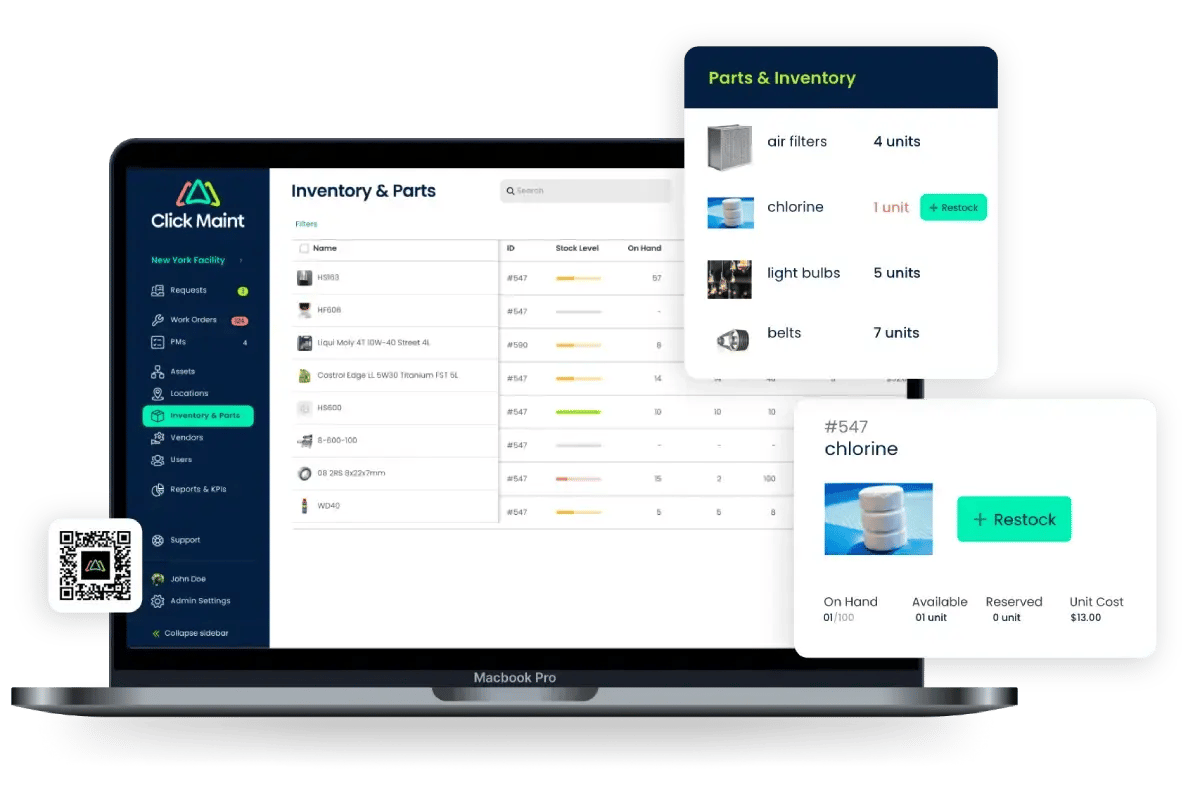

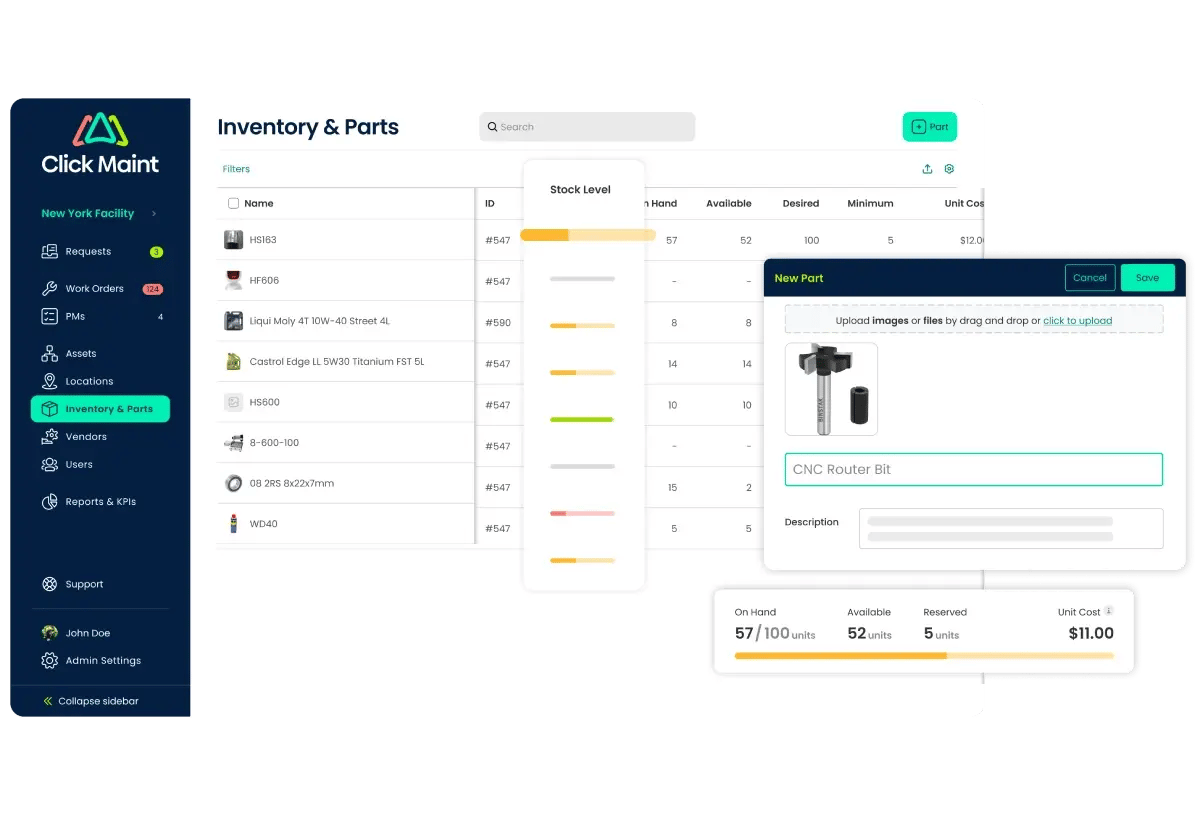

Manage spare parts, materials, and maintenance supplies, ensuring you have the right items in stock when needed to reduce downtime and delays when completing work.

Manage spare parts, materials, and maintenance supplies, ensuring you have the right items in stock when needed to reduce downtime and delays when completing work.

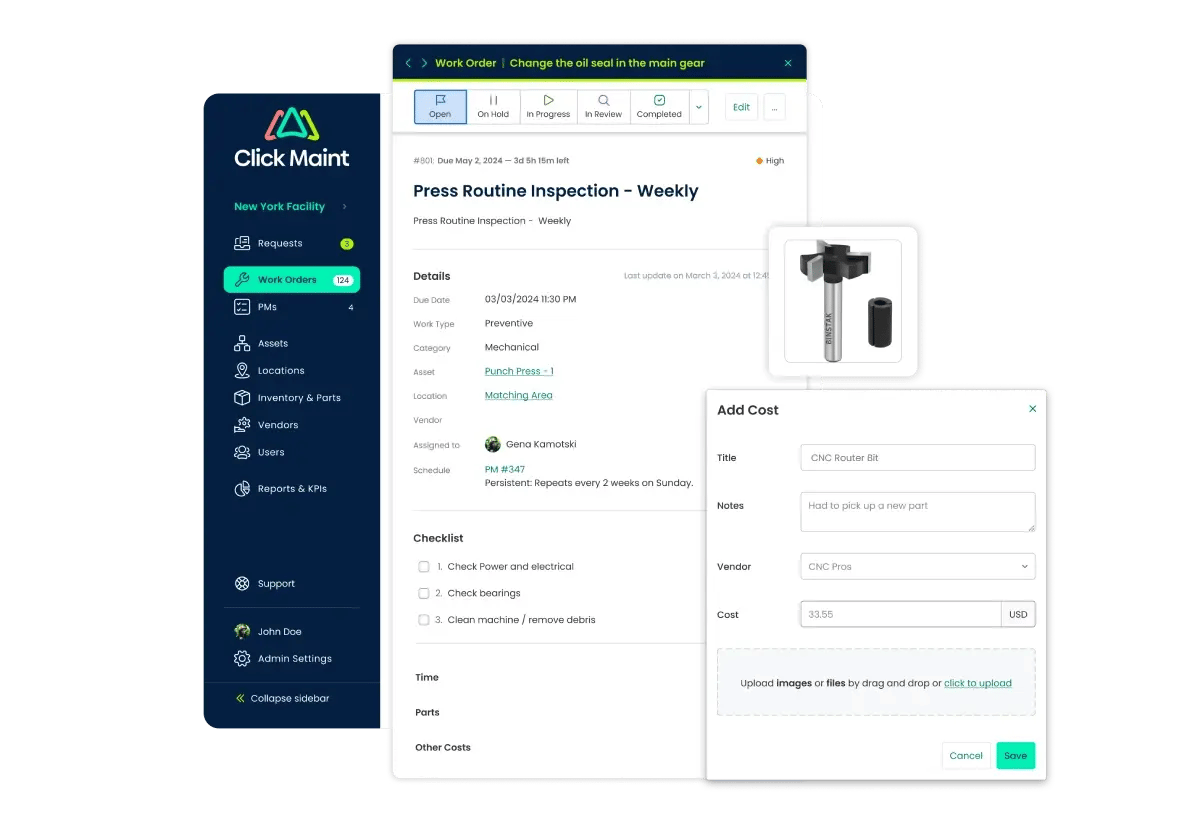

Track and estimate costs for maintenance tasks and work orders, enabling effective budgeting and cost management.

Track and estimate costs for maintenance tasks and work orders, enabling effective budgeting and cost management.

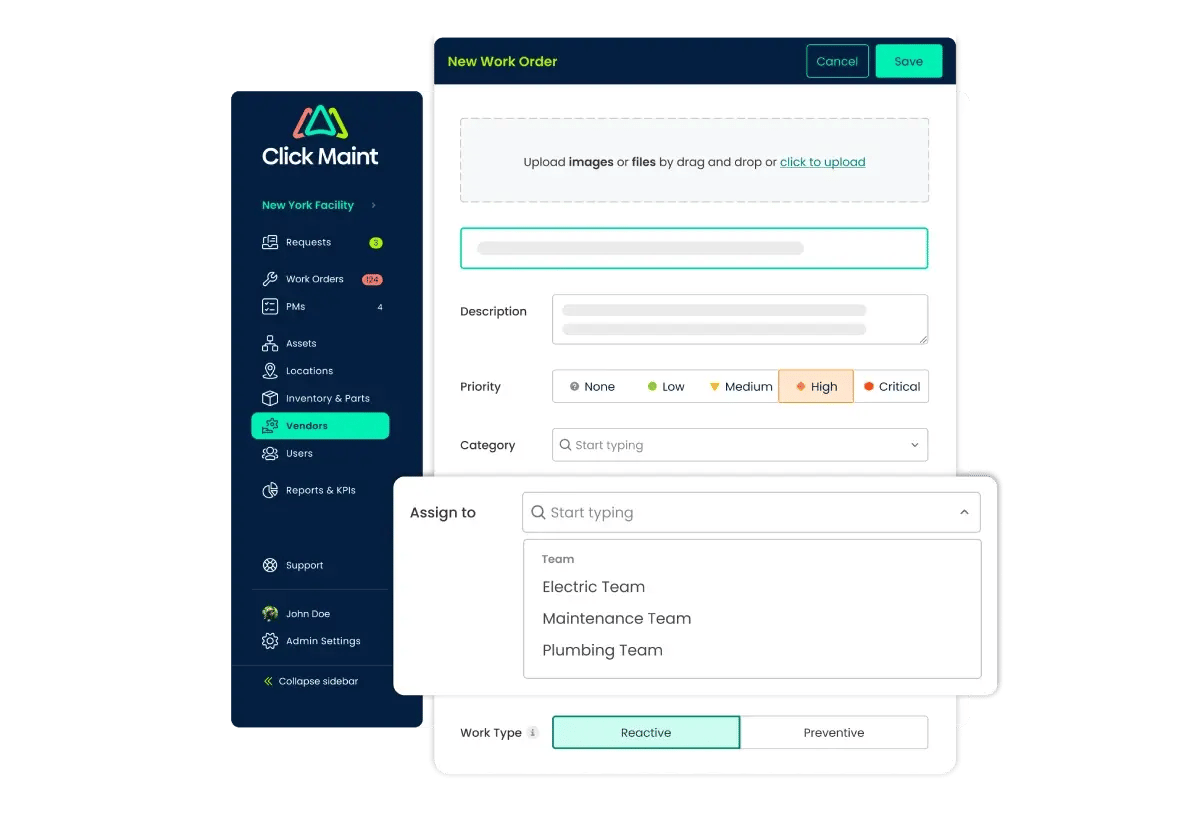

Coordinate the assignment and dispatch of maintenance teams, optimizing maintenance scheduling and planning and response time for service requests.

Coordinate the assignment and dispatch of maintenance teams, optimizing maintenance scheduling and planning and response time for service requests.

Manage maintenance tasks and work orders specific to commercial and residential buildings, ensuring building upkeep and high-quality service.

Manage maintenance tasks and work orders specific to commercial and residential buildings, ensuring building upkeep and high-quality service.

Oversee maintenance jobs from assignment to completion, ensuring tasks are completed on schedule and follow standard procedures.

Oversee maintenance jobs from assignment to completion, ensuring tasks are completed on schedule and follow standard procedures.

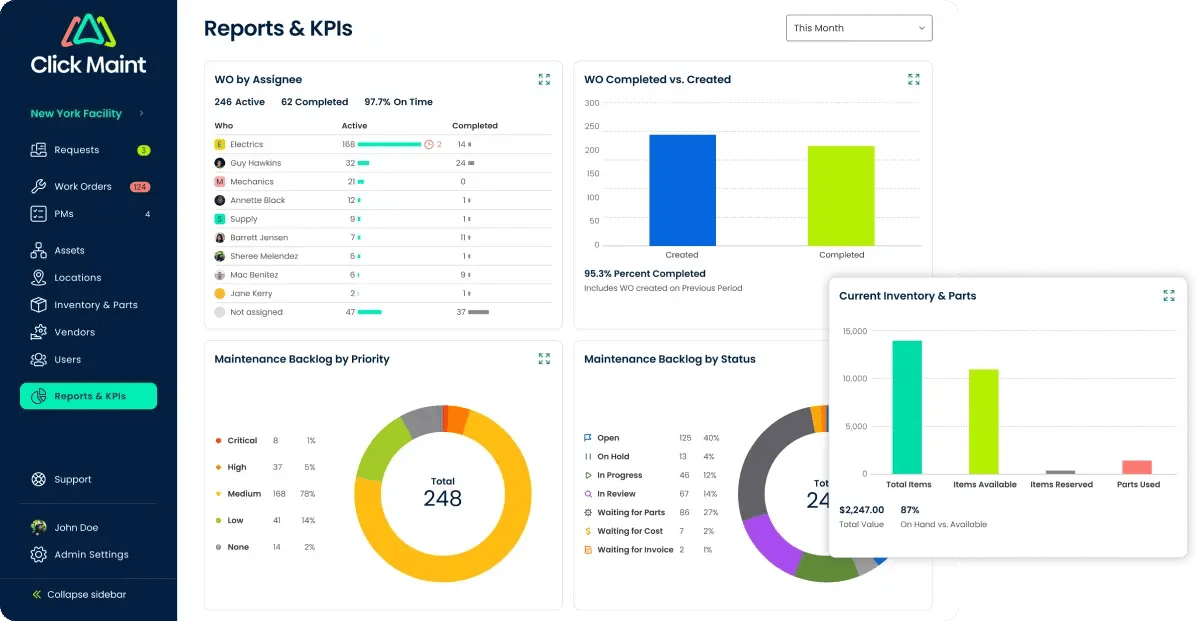

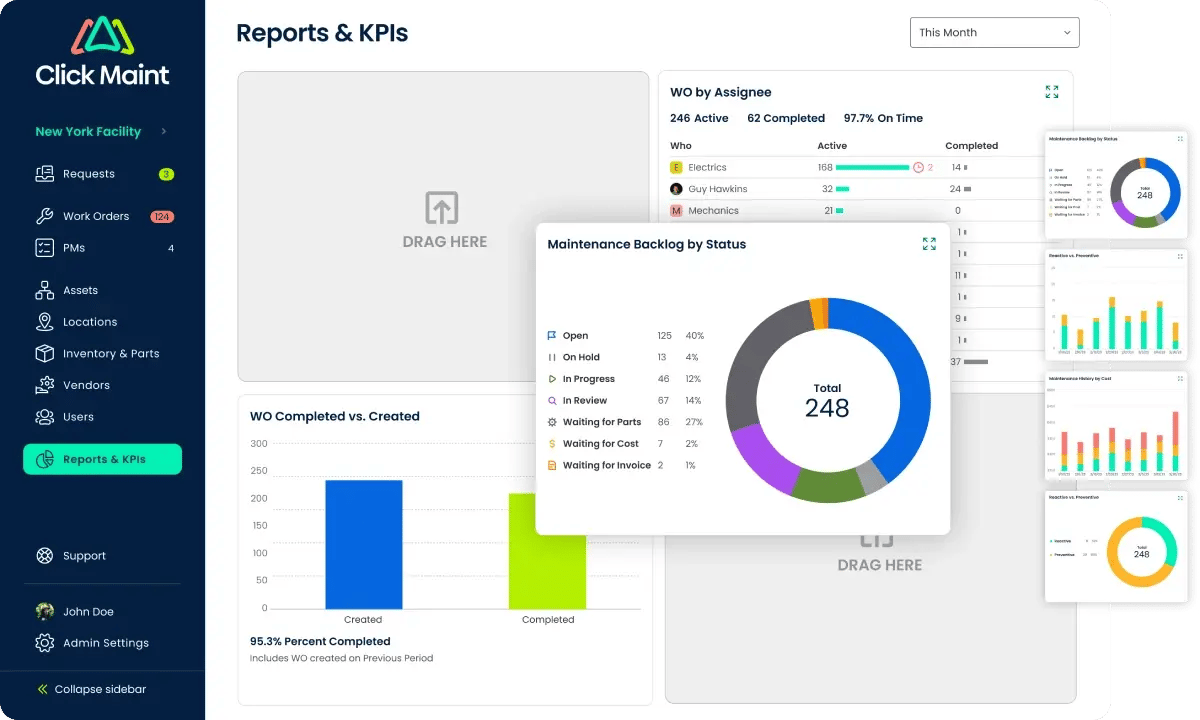

Generate reports and analyze maintenance data to identify trends, improve processes, and support data-driven decision-making.

Generate reports and analyze maintenance data to identify trends, improve processes, and support data-driven decision-making.

Maintain detailed records of past maintenance activities, supporting audits, compliance, and future maintenance planning.

Maintain detailed records of past maintenance activities, supporting audits, compliance, and future maintenance planning.

Manage maintenance personnel, including task assignment, scheduling, skills tracking, performance, and labor cost and utilization.

Manage maintenance personnel, including task assignment, scheduling, skills tracking, performance, and labor cost and utilization.

Oversee all aspects of facility maintenance, including equipment management, incident response, and vendor relationships.

Oversee all aspects of facility maintenance, including equipment management, incident response, and vendor relationships.

Automate the scheduling of recurring maintenance tasks, ensuring consistency and reduced manual effort.

Automate the scheduling of recurring maintenance tasks, ensuring consistency and reduced manual effort.

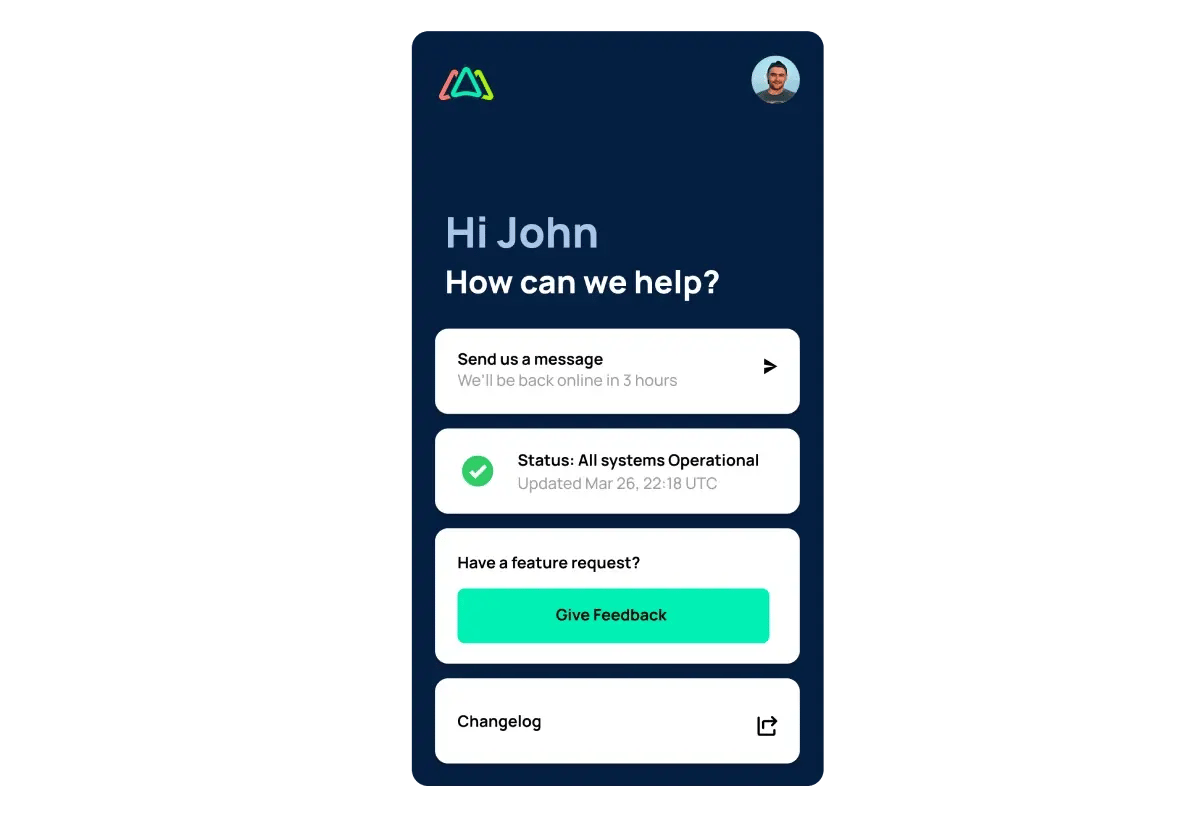

Access support resources and training materials from our knowledge base and Youtube channel to help users get the most out of the CMMS software.

Access support resources and training materials from our knowledge base and Youtube channel to help users get the most out of the CMMS software.

Use automated reminders and to-do lists to ensure maintenance tasks are completed on time and with consistency.

Use automated reminders and to-do lists to ensure maintenance tasks are completed on time and with consistency.

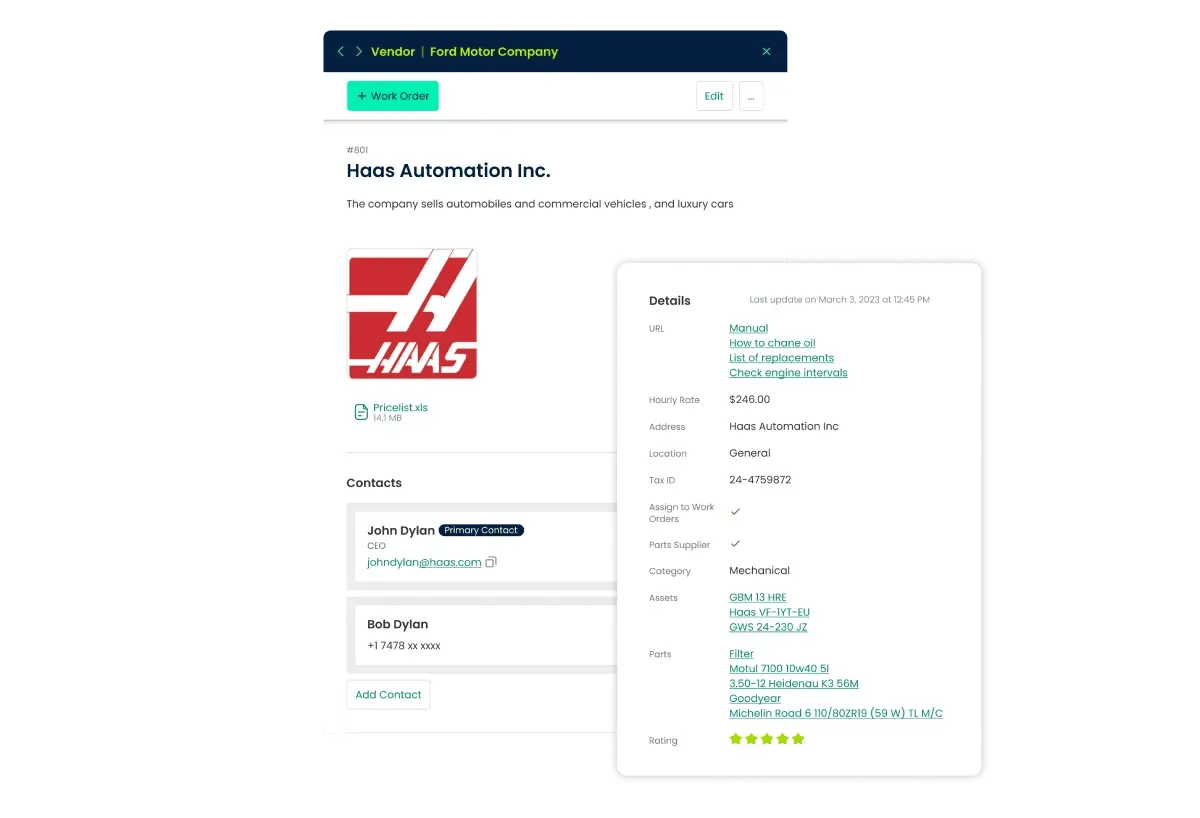

Coordinate with external vendors, managing service contracts and ensuring timely delivery of materials and services.

Coordinate with external vendors, managing service contracts and ensuring timely delivery of materials and services.

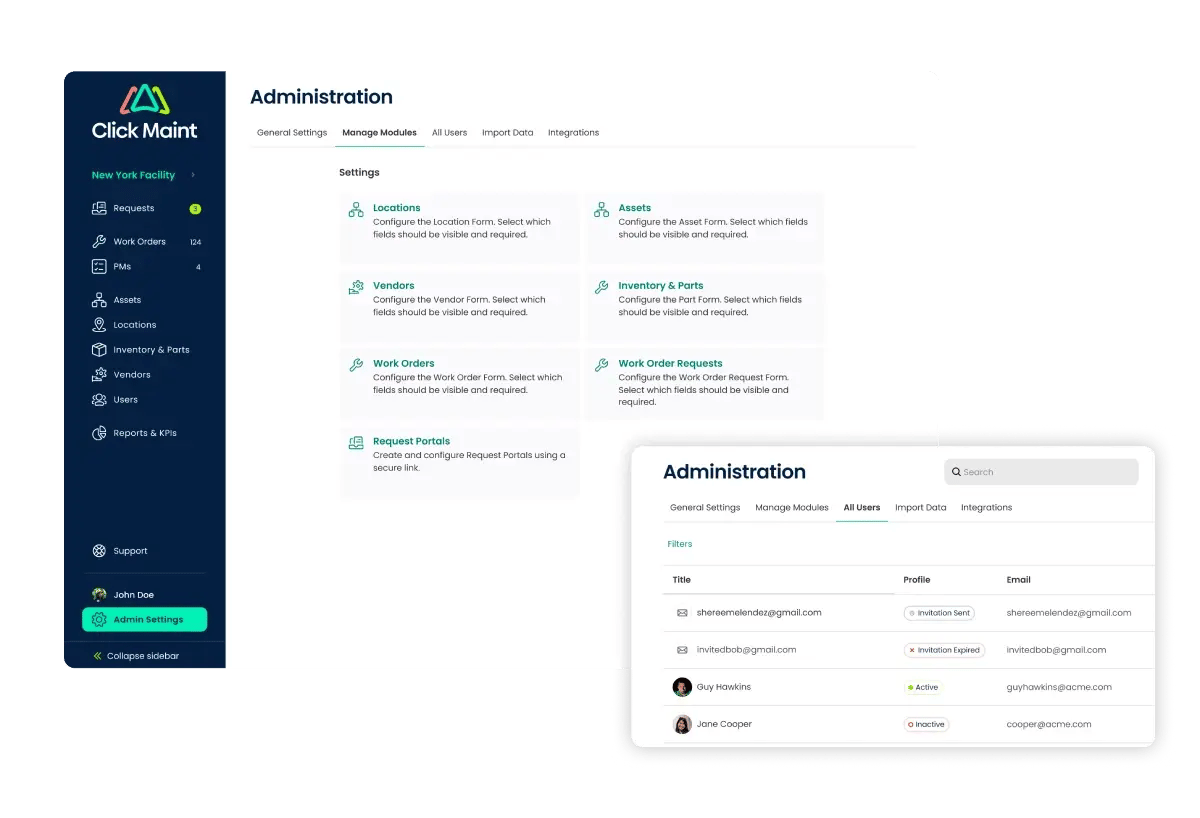

Define user roles and permissions to ensure data security and control access to sensitive information.

Define user roles and permissions to ensure data security and control access to sensitive information.

Configure dashboards to display key performance indicators (KPIs) and other important metrics for quick insights.

Configure dashboards to display key performance indicators (KPIs) and other important metrics for quick insights.

Disclaimer- The information provided in this feature comparison has been sourced from multiple review websites. We do not guarantee the accuracy or completeness of the information and advise the user to exercise discretion and make an informed decision while choosing a solution.

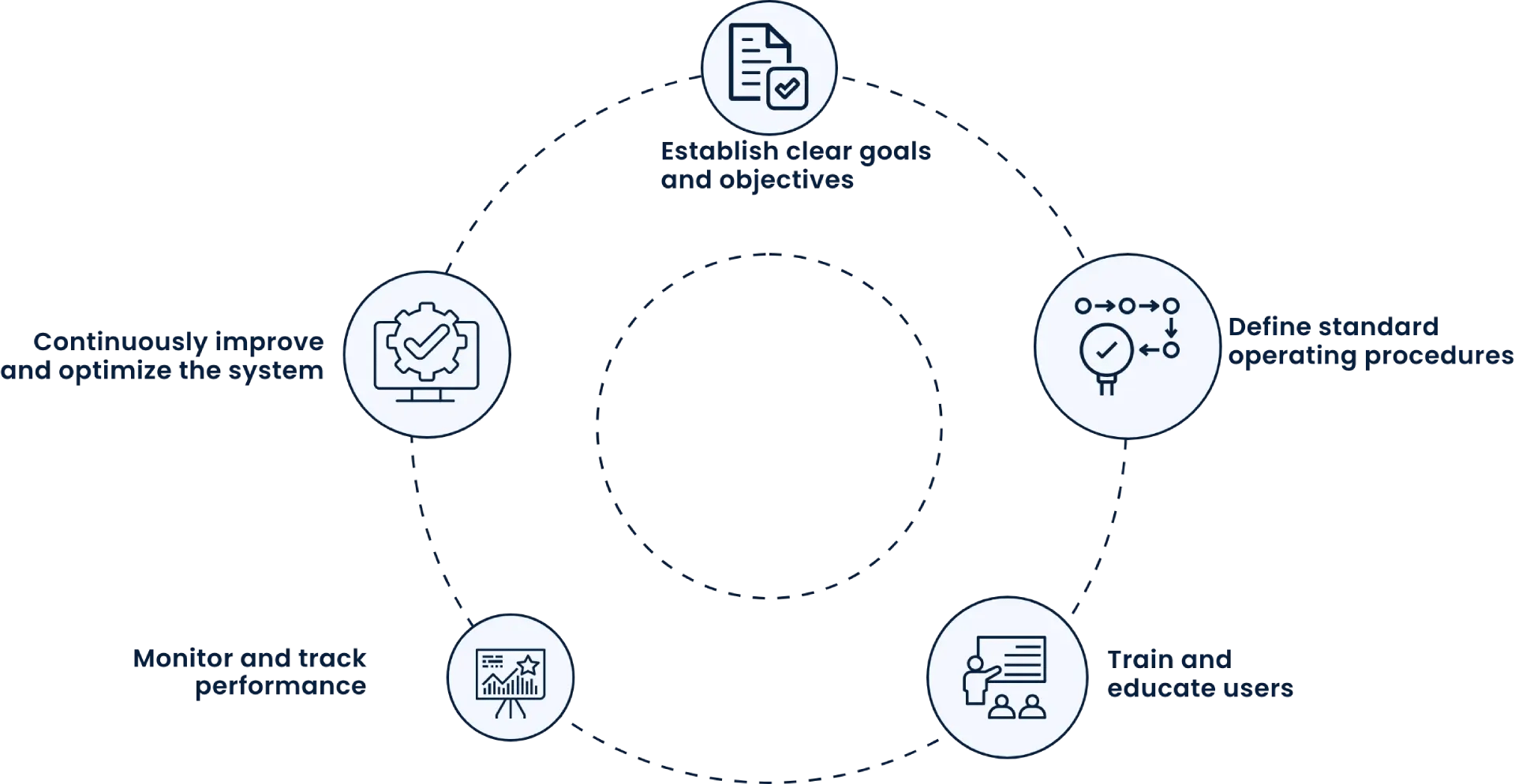

This involves creating a comprehensive list of equipment that requires preventive maintenance, outlining the maintenance tasks, and determining the frequency of maintenance.

This involves scheduling the maintenance tasks and assign them to relevant technicians based on their importance and urgency. This is done via a maintenance software.

Repairs, replacements, and inspections, are then recorded in a centralized database. This data can be used to analyze equipment performance, detect trends, and forecast future maintenance needs.

Regular inspections are critical to identify potential issues and prevent equipment failure. Inspections involve checking for wear and tear, lubrication, and cleaning equipment.

Ongoing monitoring of equipment performance can detect anomalies and potential issues, allowing for proactive maintenance. This step involves tracking various equipment performance indicators.

Identifying trends and patterns in equipment performance, allows for more informed decision-making regarding maintenance scheduling and resource allocation.

Once potential issues are identified, corrective actions must be implemented immediately to prevent equipment failure.

PM software helps manufacturers optimize equipment uptime, reduce maintenance costs, and ensure compliance with safety regulations.

Healthcare facilities maintain critical medical equipment, ensuring patient safety and regulatory compliance while also reducing downtime and repair costs.

Transportation companies keep their vehicles and equipment in optimal condition, reducing downtime and repair costs while also ensuring compliance with safety regulations.

Facilities managers maintain critical building systems, reducing downtime, and minimizing repair costs, while also ensuring compliance with safety regulations and extending the lifespan of assets.

Farmers maintain their equipment, increasing efficiency, reducing downtime, and ensuring compliance with safety regulations, ultimately leading to improved crop yields and profitability.

Industrial preventive maintenance software helps energy companies manage their complex infrastructure and equipment, ensuring high levels of uptime, safety, and regulatory compliance.

Colleges and universities maintain their campus buildings and equipment, ensuring student safety, reducing downtime and minimizing repair costs.

Preventative maintenance software helps hotels and resorts maintain their properties, ensuring guest satisfaction and minimizing disruptions to operations.

Stadiums and arenas maintain their facilities and equipment, ensuring a positive guest experience, reducing downtime, and minimizing repair costs.

Cities and towns maintain their public infrastructure, ensuring safety, reducing downtime, and minimizing repair costs, ultimately leading to improved quality of life for residents.

PM software helps retailers and restaurant owners maintain their buildings and equipment, ensuring customer satisfaction, reducing downtime, and minimizing repair costs.

PM maintenance software helps religious institutions and non-profits maintain their facilities and equipment, ensuring facilities are safe, running efficiently and minimizing repair costs.

Plant managers maintain critical manufacturing equipment, ensuring compliance with safety regulations, reducing downtime, and minimizing repair costs, ultimately leading to increased productivity and profitability.

Maintenance managers optimize their maintenance schedules, reducing downtime, and repair costs, while also ensuring compliance with safety regulations and extending the lifespan of equipment.

Fleet managers keep their vehicles in optimal condition, reducing downtime, minimizing repair costs, and ensuring compliance with safety regulations, ultimately leading to increased fleet efficiency and profitability.

Preventative maintenance software helps facility managers maintain critical building systems, ensuring safety and compliance with regulations while also reducing downtime, and minimizing repair costs.

Property managers maintain critical building systems, ensuring safety and compliance with regulations, reducing downtime, and minimizing repair costs, ultimately leading to increased tenant satisfaction and profitability.

Preventative maintenance software helps operations managers optimize their maintenance activities, reducing costs, improving efficiency, and maximizing uptime, ultimately leading to increased profitability and success.

Preventative maintenance software helps equipment operators keep their equipment in optimal condition, ensuring safety and extending the lifespan of assets while also reducing downtime and repair costs.

Preventative maintenance software helps compliance officers keep up with preventive maintenance compliance and ensure safety regulations and best practices are followed, reducing the risk of accidents or fines.

Finance managers optimize maintenance budgets, reducing costs while also ensuring that equipment is maintained in optimal condition, ultimately leading to increased profitability.

Health and safety managers ensure that businesses are complying with safety regulations, reducing the risk of accidents or fines, and promoting a culture of safety.

PM maintenance software is a computer program designed to help businesses schedule, track, and manage maintenance activities proactively. It automates preventive maintenance, creates schedules, and facilitates inspections, helping prevent equipment breakdowns, downtime, and costly repairs.

The PM maintenance software also manages asset information, work orders, spare parts inventory, and compliance with regulations. By using preventive maintenance software, organizations can extend asset lifespan, enhance reliability, and increase operational efficiency.

The history of preventive or preventative maintenance software dates back to the early days of computerized maintenance management systems (CMMS) in the 1960s. These systems were primarily used to manage work orders, inventory, and equipment records.

In the 1980s and 1990s, the focus shifted towards predictive maintenance, which used sensors and other technologies to monitor equipment performance and predict failures. However, this approach was expensive and required a high level of technical expertise. As computing power increased and software became more sophisticated, the focus returned to preventive maintenance in the 2000s.

The development of web-based software and mobile apps made it easier to manage maintenance tasks and track equipment performance.

Today, preventative maintenance software has evolved to include features such as asset tracking, work order management, scheduling, reporting, and analytics. With the integration of the Internet of Things (IoT) and artificial intelligence (AI), the future of preventive maintenance software looks promising, with even more advanced capabilities to improve equipment performance and efficiency.

Yes, one of the big preventative maintenance software benefits is that it can be integrated with other business systems such as ERP, CRM, and other business applications. Integration enables seamless data flow and provides a comprehensive view of maintenance operations, enhancing decision-making and improving efficiency. It also eliminates data silos and reduces the need for manual data entry, saving time and resources.

The cost of preventative maintenance software varies depending on the features, customization options, and vendor. Most vendors offer subscription-based pricing models that range from a few hundred to several thousand dollars per month. Additionally, some vendors charge implementation and training fees. It's essential to consider the total cost of ownership, including software costs, training, and support, before making a decision.

The training required to use preventative maintenance software depends on the complexity of the system and the organization's needs. Most vendors offer training programs that range from online courses to on-site training. The training typically covers system navigation, asset and work order management, preventive maintenance scheduling, and reporting. It's essential to ensure that all users receive proper training to maximize the benefits of the software.

The training required to use preventative maintenance software depends on the complexity of the system and the organization's needs. Most vendors offer training programs that range from online courses to on-site training. The training typically covers system navigation, asset and work order management, preventive maintenance scheduling, and reporting. It's essential to ensure that all users receive proper training to maximize the benefits of the software.

When selecting preventive maintenance software, the key features to look for include work order management, asset tracking, scheduling and notifications, inventory management, and reporting/analytics. Work order management allows maintenance teams to track tasks, assign resources, and prioritize jobs. Asset tracking provides detailed histories of equipment maintenance, which helps optimize performance and extend asset lifespans. Scheduling and notifications automate the planning of maintenance activities, ensuring that critical tasks are never missed. Inventory management ensures parts and tools are always available when needed, reducing downtime. Finally, reporting and analytics give insight into maintenance performance, cost control, and equipment efficiency. Depending on your industry, mobile accessibility and IoT integration may also be essential for real-time monitoring and flexibility.

Yes, preventative maintenance software is suitable for businesses of all sizes. Preventive maintenance software for small companies is a good step towards digitalization. Small businesses with a few assets can benefit from basic preventive maintenance features, while larger organizations can leverage advanced features such as predictive maintenance and analytics. Many vendors offer customizable solutions to accommodate the specific needs of different-sized organizations.

The ROI of preventative maintenance software can be measured by calculating the reduction in downtime and repair costs, increased asset reliability, and improved productivity. Additionally, factors such as increased asset lifespan, improved safety, and compliance can be considered. The total cost of ownership, including software costs, implementation, and training, should also be factored in. Some teams also take the free preventive maintenance software approach to pursue ROI.

Preventive software maintenance helps reduce downtime by proactively scheduling maintenance activities before equipment failure occurs. By monitoring asset performance data and automatically triggering maintenance tasks based on usage, time, or condition, preventive maintenance software ensures that equipment stays in optimal working condition. This predictive approach minimizes unplanned breakdowns that can disrupt operations and lead to costly downtime. The software also helps teams track spare parts and manage inventory levels, so parts are always available when needed, reducing delays in repairs.

Moreover, detailed reporting features allow businesses to analyze trends, such as the frequency of equipment failures or underperforming assets, enabling data-driven decisions for future maintenance planning. Ultimately, preventive maintenance software extends asset lifecycles and boosts operational efficiency, which directly translates into reduced downtime and lower maintenance costs.