CMMS Implementation Services Are Not a Feature — They’re a Strategic Choice

By 2026, CMMS platforms will no longer be the limiting factor in maintenance performance. Most CMMS systems can schedule work, track assets, manage spares, and run on mobile devices. Yet many organizations still fail to realize meaningful improvements in uptime, labor productivity, or cost control.

The reason is not technology. It concerns how the CMMS is implemented and who bears responsibility for its implementation.

The maintenance industry continues to treat CMMS implementation services as a checklist or a procurement transaction. In practice, most CMMS implementations are delivered by the software vendors themselves, using standardized playbooks refined across hundreds of deployments. This approach prioritizes speed, repeatability, and platform consistency, making it well-suited to the rapid deployment of systems. However, standardization also means that implementation is optimized for the software’s out-of-the-box, rather than for the organization’s operational realities or long-term change requirements.

In reality, implementation is a strategic delivery decision that determines whether a CMMS becomes an adaptive living system of record or a digital filing cabinet. The CMMS delivery model plays a critical role in generating CMMS ROI, a factor that often gets overlooked.

Preventive Maintenance Paradox to CMMS Paradox

The article on the Preventive Maintenance Paradox describes a long-standing contradiction in maintenance management. Although preventive maintenance (PM) is widely promoted as a best practice, many organizations fail to achieve meaningful results. Decades of studies and practitioner experience show that a large percentage of companies report their PM programs as ineffective, despite widespread adoption.

The paradox arises because the success of preventive maintenance depends more on organizational behavior and discipline than on the technical concept of task scheduling. As maintenance expert Terry Wireman has emphasized for years, preventive maintenance only works when it is properly designed, executed consistently, and supported by management. Otherwise, it becomes “busy work” that consumes resources without reducing failures.

The article further highlights three primary causes.

- First, reactive maintenance gets attention; preventive maintenance doesn’t. After all, breakdowns are visible, but preventive maintenance isn’t.

- Second, a mechanical approach to preventive maintenance. Because of skill gaps resulting from insufficient training, PM tasks aren’t undertaken on a diagnostic basis. This leads to missed early signs of failure.

- Third, lack of discipline erodes results. PM schedules may exist on paper or in a CMMS, but are skipped, deferred, or poorly executed under production pressure.

The article reinforces Terry Wireman’s long-held position that preventive maintenance must be treated as a managed process rather than a checklist. Simply increasing PM volume does not guarantee reliability; in fact, poorly targeted PM can increase costs and downtime. True preventive maintenance requires clear standards, competent technicians, intense supervision, and consistent execution.

The key takeaway is that the preventive maintenance paradox is not a failure of PM theory, but a failure of implementation. When organizations commit to discipline, skills development, and leadership support, PM consistently delivers lower breakdown rates, improved uptime, and reduced total maintenance cost.

It is no different in the case of “The CMMS Paradox.” CMMS software has gotten better, but outcomes haven’t. CMMS vendors have dramatically improved usability, cloud architecture, and feature depth. Adoption should be easier than ever.

Yet performance outcomes remain inconsistent. Preventive maintenance compliance improves, then plateaus. Reactive work reemerges because it's familiar and comfortable. Technicians bypass the system under pressure.

This paradox exists because organizations focus on what the CMMS does rather than how change is delivered. Click Maint CMMS has written extensively about how CMMS implementations are suboptimal, with over 61% of maintenance managers finding them challenging.

CMMS Implementation is No Longer an IT Activity

Software implementation is routinely treated as an IT activity because, historically, enterprise systems have been infrastructure-heavy projects focused on servers, integrations, security, and licenses. Ownership was assigned to IT because success was defined by technical milestones: installation completion, system stability, and user provisioning. CMMS implementation often falls into the same trap. Software that falls under the IT budget line (under the CIO) and includes technical configuration tasks. But this framing obscures the real work. A CMMS does not primarily involve technology change. Instead, it changes how work is requested, prioritized, executed, recorded, and evaluated on the plant floor.

A CMMS now encompasses production risk, maintenance labor allocation, spare parts cash flow, safety, compliance evidence, reliability analytics, and capital planning. This makes CMMS implementation a management and governance problem rather than a technical one. When executives delegate it entirely to IT or maintenance without structural support, the system may go live, but it has no impact on maintenance processes.

The Question Most CMMS Buyers Fail to Ask

Instead of asking “What services and support are included in our implementation plan?” buyers should ask, “Who should own the CMMS implementation and why?” Most CMMS discussions fixate on scope—what the implementation includes, how long it will take, and what it will cost. The more consequential question is rarely asked: who should implement the system, and why? That decision shapes everything that follows, from speed and value to adoption risk and data credibility, long-term scalability, and the amount of executive time ultimately spent firefighting. Once an implementation plan is chosen and the project is underway, it is difficult and expensive to reverse, making this one of the most strategic, and least examined, decisions with CMMS purchases.

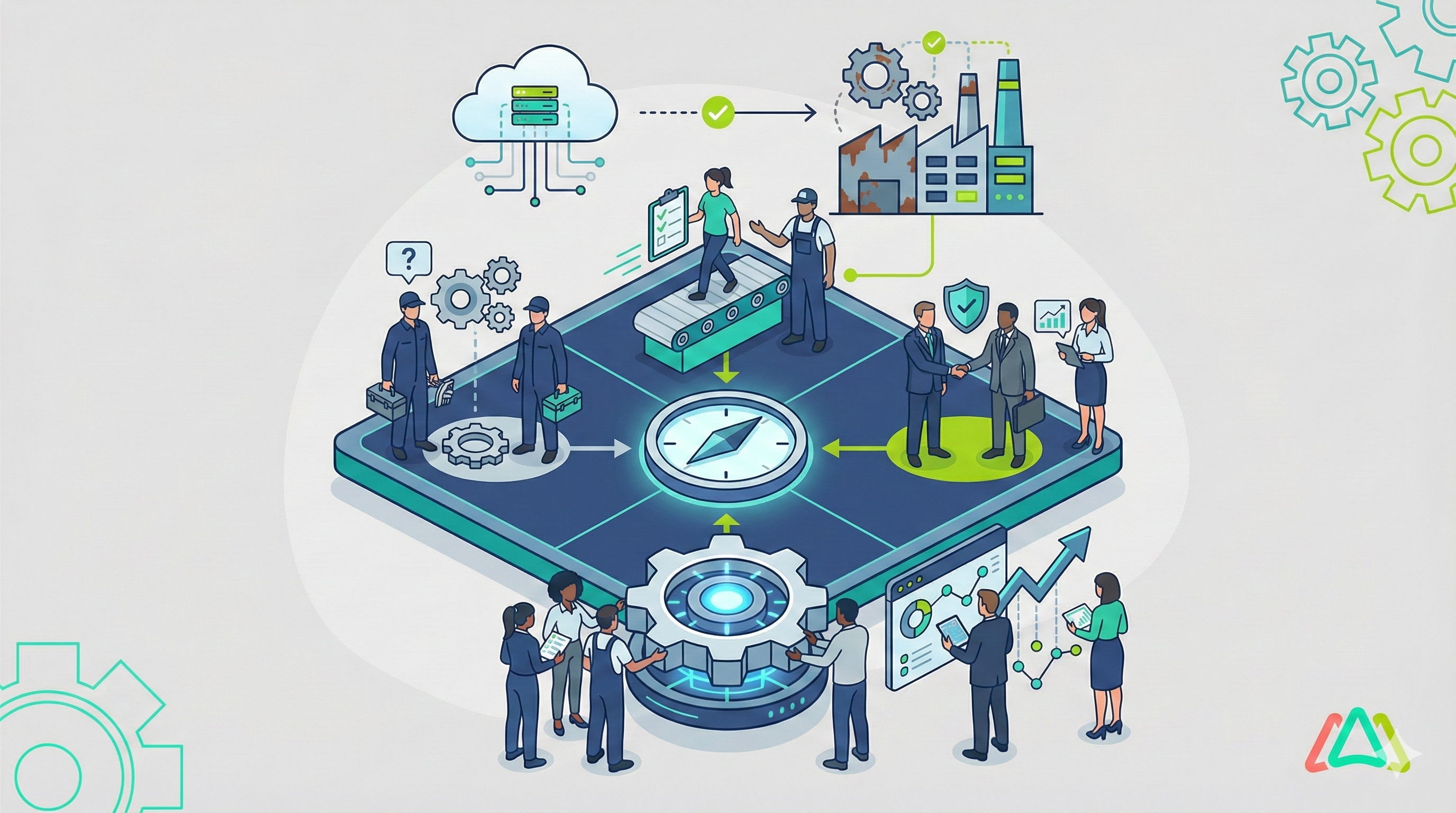

Three CMMS Implementation Delivery Models

Any CMMS implementation can be delivered with the following delivery models:

Any CMMS implementation can be delivered with the following delivery models:

- Self-Implementation

- Vendor-led implementation

- Third-party service providers

Additionally, the hybrid model will be discussed in this article. Deciding on the delivery model will depend on many factors, including the size of the team and company, complexity of implementation among others. This article does not make a recommendation regarding delivery models; it presents the pros and cons of each model.

1. Self-Implementation: Control without Capacity

Self-implementation is attractive on paper. It’s less expensive, gives complete control to the buyer, and avoids external dependency.

In practice, however, it assumes the existence of something most maintenance organizations lack: excess capacity. Maintenance leaders are rewarded for keeping assets running, not for perfect data models or workflow design. When implementation competes with breakdowns, the CMMS always loses.

Self-implementation works only when:

- The environment is simple

- Risk is low

- Internal CMMS experience and technical know-how are strong

- Leadership accepts slower returns

2. Vendor-led Implementation: Speed with Assumptions

Vendor-led services dominate the mid-market for good reason. They are structured, predictable, and fast. Vendors know their platforms better than anyone else. But vendor implementations are optimized for platform success, not always organizational fit.

They work best when:

- Processes are fairly standard

- Integrations are limited

- The CMMS is not replacing a deeply embedded system with complex and unique workflows

Without strong internal leadership, vendor-led implementations can quietly lock in suboptimal processes that scale poorly. Once rolled out, they will need fine-tuning and in some cases a lot of rework if not carefully planned and thought out in advance.

3. Third-party Partners: Risk Reduction, Higher Costs

Independent implementation partners are often misunderstood. Their goal is not to lower costs, but instead to lower the risk of CMMS implementation failure.

They become essential when:

- Downtime risk is high

- Compliance matters

- Multiple sites or business units are involved

- ERP integration is non-negotiable

The Rise of the Hybrid Model

When maintenance teams are fire-fighting, it’s nearly impossible to think strategically. Yet, governance and change management are strategic goals and are critical to a successful CMMS implementation.

Why Governance Beats Methodology Every Time

Discussions about CMMS implementation often center on methodology—agile vs. waterfall, or phased vs. big-bang rollouts. However, these debates overlook the true factor that dictates CMMS success. What matters more is governance: visible executive sponsorship, clear decision rights, measurable adoption metrics, and the willingness to pause, adjust, or reset when expected behavior changes do not materialize. Without this governance structure, even the most carefully planned implementation will succeed on paper while failing in day-to-day operations.

The Real Reason CMMS Projects Often Disappoint

CMMS implementation disappoints leadership not because they fail outright, but because they focus on activities rather than outcomes.

The following summarize the realities of most CMMS implementations.

- System live ≠ system is used

- Data entered ≠ trusted & reliable data

- PM scheduled ≠ PM executed

A system going live does not guarantee consistent use, and data entry does not guarantee accuracy. Scheduled preventive maintenance does not guarantee that preventive maintenance tasks are being executed as intended. Frustration sets in when success is defined by configuration milestones rather than by behavior change, leaving executives with a functioning system that fails to improve reliability, cost control, or operational performance materially.

What Forward-thinking Leaders do Differently

Forward-thinking leaders approach CMMS implementation in fundamentally different ways. High-performing organizations treat it as a change program rather than a software project, a leadership responsibility rather than a task to be delegated, and an investment in operational capabilities rather than a sunk cost. They carefully select their implementation delivery model, explicitly fund adoption and behavior change, and measure success through weekly operational signals instead of annual reports, ensuring the system continuously drives reliability, productivity, and business value.

The Hybrid CMMS Implementation Model

The most effective organizations are increasingly hybrid:

- Vendors configure the system

- Third parties manage change, data, and integrations

- Internal teams retain ownership and accountability

This model reflects a mature understanding where sustaining the CMMS implementation matters more than the speed of implementation. 2026 is expected to see more of this hybrid CMMS implementation model.

The Strategic Takeaway

Currently, with numerous CMMS options on the market, CMMS platforms can be considered a commodity. CMMS implementation plans, however, are not. The difference between a CMMS that transforms maintenance and one that quietly fades into the background is not the software — it’s the delivery model, governance, and leadership attention behind it.

The organizations that understand this stop asking:

“What does CMMS implementation include?”

And start asking:

“How do we want this system to change the way we operate, and who is best positioned to make that happen?”

That is the question that separates CMMS buyers from CMMS leaders.

Addressing this question alone is not enough, though. These services must be readily available in the marketplace. Currently, the supply of third-party CMMS implementation services is primarily controlled by large system integrators who focus on high-value enterprise clients. Paradoxically, the CMMS buyer market, by volume, is largely comprised of small businesses, a segment often overlooked by these integrators. The question remains: Will 2026 be the year these two diverging segments of the market converge? We will have an answer in a year's time.

TABLE OF CONTENTS

Keep Reading

School facilities are busy, high-traffic places. On average, 45.8 million students attend ...

10 Feb 2026

There is also no shortage of acronyms in the maintenance world. So, here is one more to add ...

6 Feb 2026

You may be wondering: if you are already using CMMS software in your organization, aren’t ...

5 Feb 2026

Although artificial intelligence (AI) has been around since the mid-1950s, it wasn’t until ...

3 Feb 2026

Fire safety is often treated as a compliance checkbox rather than an ongoing operational ...

30 Jan 2026

Schools are regarded as places of learning where children are exposed to the basics of ...

29 Jan 2026

Facility maintenance, much like running a business, defies one-size-fits-all solutions. The ...

27 Jan 2026

When we think of inspections, we usually think about ensuring regulatory compliance and ...

23 Jan 2026

In maintenance operations, having the right spare parts in the right amount and at the right ...

22 Jan 2026

The relentless march of technology continuously reshapes the industry landscape, and with it, ...

20 Jan 2026

New Year’s resolutions tend to focus on lifestyle or financial changes, often aimed at making ...

16 Jan 2026

Now that 2026 has arrived, we’ll see that manufacturing trends will matter more than ever, as ...

15 Jan 2026

Now that 2026 is here, it’s a great time to assess what can be achieved in maintenance ...

13 Jan 2026

2026 is when the role of a CMMS Software in capital allocation comes to the fore. This is the ...

12 Jan 2026

Choosing the right work order software is no longer optional for maintenance teams in 2026. ...

6 Jan 2026

Spare parts management within maintenance can make the difference between a problem-free ...

16 Dec 2025

Every maintenance team eventually faces the same question: When should we repair, and when ...

12 Dec 2025

Enterprise Asset Management (EAM) software has become a cornerstone for organizations aiming ...

12 Dec 2025

Unexpected equipment breakdowns can disrupt operations, increase repair costs, and reduce ...

11 Dec 2025

Businesses are always looking for ways to improve efficiencies, reduce costs, and improve ...

9 Dec 2025