Manufacturing Trends That Will Shape 2026

Now that 2026 has arrived, we’ll see that manufacturing trends will matter more than ever, as they continue to evolve faster than at any time in modern history. This is mainly because 2026 manufacturing trends are being driven by a convergence of forces that have not existed before, including advanced automation, artificial intelligence, global instability, and rapid digital transformation. Previously, manufacturing evolved in steady, predictable cycles. However, innovation is occurring continuously today, forcing manufacturers to adapt faster or risk being left behind. Equipment, software, and workforce expectations are changing simultaneously, making this one of the most disruptive periods the industry has ever experienced.

We’ll see that some of the most powerful manufacturing trends are being shaped by external forces that manufacturers can no longer control. These factors include fragile global supply chains, geopolitical risk, shipping costs, and material shortages, which continue to create instability and uncertainty. At the same time, AI is transforming how factories plan, operate, and maintain their assets. Labor shortages are pushing manufacturers to automate and digitize, while sustainability requirements are forcing companies to rethink energy use, waste, and compliance. Together, these forces are redefining how manufacturing must operate in 2026.

To overcome these challenges, manufacturers will need to understand and act on the most critical manufacturing trends to gain a potent competitive edge. Companies that invest in digital systems, predictive maintenance, automation, and sustainability will operate at lower cost, with higher uptime, and greater flexibility. Alternatively, those that ignore these trends will struggle with inefficiency, compliance risk, and shrinking margins. The bottom line is that, in 2026, manufacturing success will depend not just on what you make, but on how intelligently, sustainably, and resiliently you make it.

While many of the manufacturing trends shaping 2026 are driven by large, highly automated enterprises, it’s important to recognize that not all manufacturers face the same operational realities. Smaller and mid-sized manufacturing businesses often operate with tighter budgets, leaner teams, and fewer IT resources. For these organizations, success does not require adopting every emerging technology; rather, it requires choosing practical solutions that improve reliability, visibility, and control without adding unnecessary complexity.

Many advanced technologies, such as AI-driven optimization, Industrial IoT, and predictive maintenance, deliver strong returns in high-volume or asset-intensive environments. However, for many smaller manufacturers, foundational capabilities such as automated preventive maintenance scheduling, inspection tracking, work order history, and downtime visibility often deliver the greatest immediate value. Let’s explore the most relevant manufacturing trends in 2026.

Is AI-Driven Manufacturing Becoming the New Standard?

Once considered an interesting new approach, AI is no longer experimental. Today, AI is one of the most powerful manufacturing trends shaping 2026. Increasingly, artificial intelligence is being embedded into production planning, demand forecasting, quality inspection, and equipment monitoring. By analyzing large volumes of machine and operational data, AI systems can predict failures before they occur, optimize production schedules, and reduce scrap. Manufacturers that use AI effectively can experience significant gains in efficiency, uptime, and decision-making speed.

One of the most powerful applications of AI is in predictive and prescriptive maintenance. AI-driven CMMS platforms monitor vibration, temperature, energy use, and operational patterns to predict failures weeks in advance. The technology goes well beyond predictions by providing the most cost-effective corrective actions, automatically scheduling work, and ensuring the right parts and technicians are available. This advanced capability dramatically reduces unplanned downtime, extends asset life, and supports overall manufacturing success. At the same time, CMMS Software for manufacturing is expected to stay relevant for a large segment of the sector.

AI can also transform quality control and production efficiency. Computer vision systems can inspect products faster and more accurately than human inspectors, identifying defects that would otherwise go unnoticed. On the other hand, machine-learning algorithms continuously fine-tune production parameters to reduce scrap, increase throughput, and stabilize output. As this manufacturing trend continues to evolve, organizations will become increasingly self-optimizing, using data and intelligence to improve performance without constant human intervention.

Smart Factories and the Industrial Internet of Things (IIoT)

One of the most transformative manufacturing trends in 2026 is the rise of fully connected smart factories. IIoT sensors can collect real-time data from machines, conveyors, energy systems, and environmental controls. This data enables manufacturers to monitor performance in real time, spot bottlenecks, and automate responses to issues.

More specifically, IIoT transforms raw machine data into actionable intelligence. Sensors track vibration, temperature, speed, pressure, and energy use across every asset in the plant. When this data is combined with analytics platforms and CMMS systems, early detection of equipment issues, automatic work order creation, and precise maintenance scheduling are possible. Instead of reacting to breakdowns, maintenance teams can intervene before failures occur, dramatically improving uptime and asset reliability.

Beyond maintenance, IIoT enables smarter production planning and higher product quality. Production managers can identify bottlenecks, identify which machines are underperforming, and assess how environmental conditions affect output. The system’s automated alerts and digital dashboards help teams adjust production in real time, reducing waste and increasing throughput. The result is that manufacturing factories will become increasingly self-aware, capable of optimizing their own performance through data-driven automation.

Advanced technologies such as AI-powered predictive maintenance, Industrial IoT sensors, and fully connected smart factories represent exciting possibilities for the future of manufacturing. However, these solutions are not always practical or necessary for every operation. They often require significant upfront investment, technical expertise, ongoing data management, and large asset populations to justify their cost.

For many manufacturing businesses, especially small and mid-sized facilities, focusing on consistent preventive maintenance execution can achieve substantial reliability gains without the expense of advanced analytics or sensor networks. Automating PM schedules, standardizing inspections, tracking asset history, and capturing downtime data allow teams to make better decisions using information they already have.

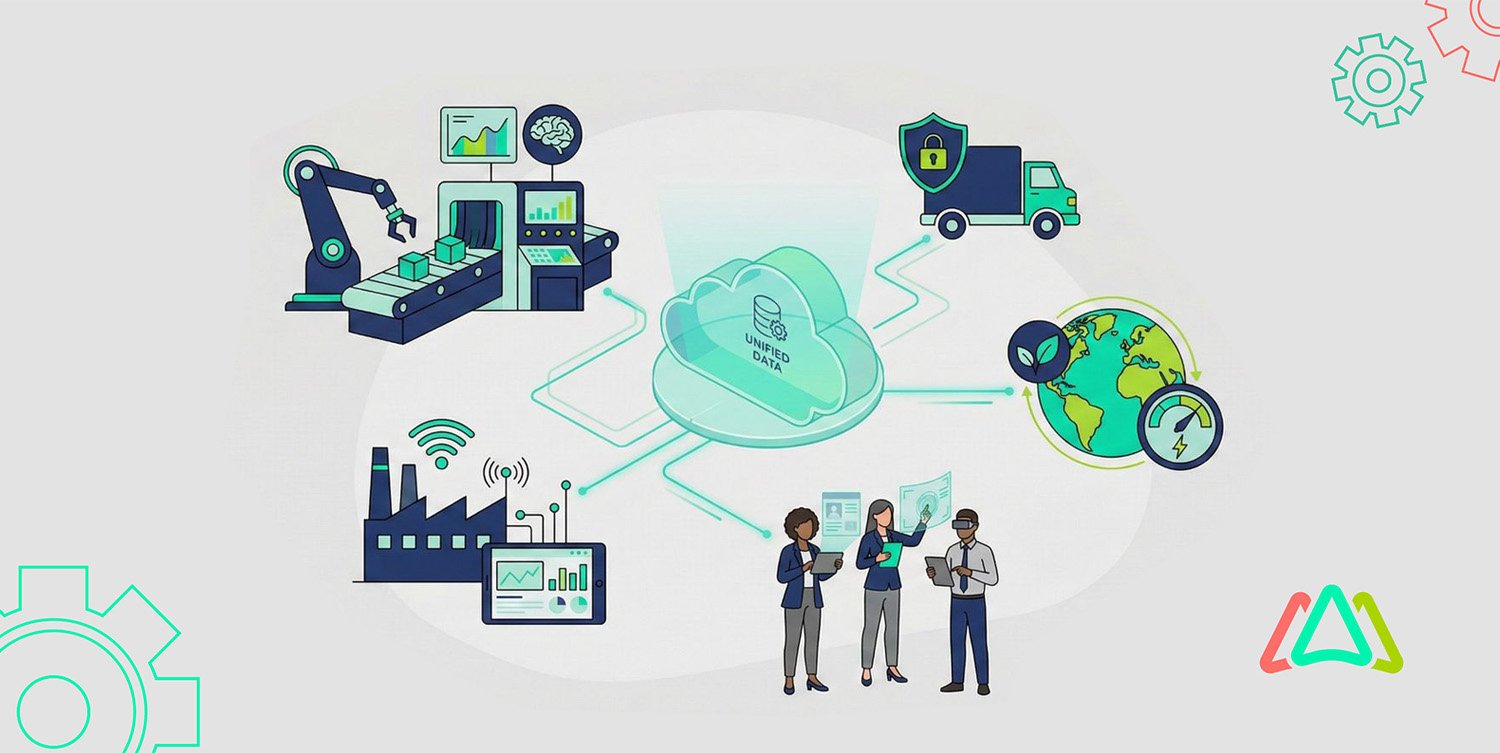

Emergence of the Unified Data Layer in Manufacturing

One of the most critical manufacturing trends shaping 2026 is the move toward a unified data layer that integrates all core operational systems into a single, coherent environment. Previously, manufacturers struggled with fragmented data spread across ERP, CMMS, MES, SCADA, quality systems, and spreadsheets. These silos prevent leaders from seeing the actual state of operations, making it difficult to respond quickly to issues or plan strategically. With a unified data layer, these blind spots are eliminated by creating a real-time, plant-wide view of performance.

By integrating machine data, maintenance records, production metrics, inventory levels, and financial information, manufacturers achieve a single source of truth, allowing operations teams to understand how asset health impacts production, how maintenance affects costs, and how inventory aligns with demand. Decision-making is no longer based on partial or outdated information. Instead, maintenance managers can see cause-and-effect relationships across the entire organization. This manufacturing trend is potent for companies managing complex, multi-site operations where consistency and visibility are essential.

A unified data layer also provides a foundation for advanced technologies such as AI, digital twins, and predictive analytics. As manufacturers adopt this manufacturing trend, they will be able to automate workflows, optimize asset utilization, and scale their operations without adding complexity, a requirement for survival.

Automation Expands Beyond Robotics

One of the most critical manufacturing trends in 2026 is the expansion of automation beyond physical machines on the factory floor. Now, comprehensive automation extends into scheduling, maintenance, compliance, inventory, and quality management. Today, software-driven automation is replacing manual processes that once slowed operations and led to human error, creating a faster and more reliable manufacturing environment.

Connected systems now automate tasks such as work order generation, parts replenishment, inspection scheduling, and regulatory reporting. For example, when an IIoT sensor detects abnormal vibration, the system can automatically trigger a CMMS work order, reserve the required spare parts, and notify the correct technician. Automation reduces response time, prevents minor issues from becoming major failures, and significantly improves asset reliability. Because of these capabilities, it represents one of the core drivers of manufacturing success.

Workforce Transformation and the Digital Skills Shift

Transforming the manufacturing workforce is one of the most underestimated manufacturing trends shaping 2026. As factories become more automated, connected, and data-driven, it is essential to keep pace with the changing skills required to operate them. Today, traditional mechanical expertise must be combined with digital literacy, data interpretation, and system management. For example. technicians, supervisors, and engineers are now expected to interact with CMMS platforms, analytics dashboards, and automated workflows as part of their daily routines.

An aging workforce and ongoing labor shortages are driving this transformation. To counter this trend, manufacturers are turning to digital tools such as mobile CMMS, augmented reality work instructions, and AI-powered diagnostics to capture and disseminate knowledge more effectively. These technologies help newer workers get up to speed while reducing dependence on a shrinking pool of highly specialized experts. These emerging innovations make this manufacturing trend essential for operational continuity.

Sustainable and Green Manufacturing Becomes Mandatory

Sustainability is one of the defining manufacturing trends of 2026 primarily because governments, investors, and customers are demanding greater transparency around energy use, emissions, and environmental impact. The result is that manufacturers are being forced to treat sustainability as a core operational metric rather than a side project. Digital tools now allow companies to track carbon output, water use, and waste in real time, turning sustainability into something that can be measured, managed, and improved.

Energy efficiency is at the center of this shift. Smart meters, IIoT sensors, and AI-driven energy management systems help manufacturers identify where power is being wasted and where equipment is operating inefficiently. Maintenance teams can now use data from CMMS platforms and energy systems to keep assets running at peak efficiency, reducing both emissions and operating costs. This creates a powerful link between sustainability and profitability, making this manufacturing trend especially attractive to maintenance teams.

The result is that, in 2026, the companies that lead in sustainable manufacturing will also be best positioned for long-term growth and resilience.

Resilient and Regionalized Supply Chains

Supply chain issues, including shipping delays, geopolitical instability, natural disasters, and material shortages, continue to pose challenges for manufacturers. As a result, one of the most crucial manufacturing trends in 2026 is a shift away from fragile, globally stretched supply chains toward more resilient, regionally balanced networks. Today, many companies are reshoring or nearshoring critical production while diversifying their supplier base to reduce dependence on any single region or vendor.

Technology plays a critical role in overcoming supply chain problems. Real-time visibility platforms now track raw materials, work-in-progress, finished goods, and transportation status across the entire value chain. When integrated with ERP and production planning systems, this data allows manufacturers to adjust schedules, reroute shipments, and prioritize high-value orders before disruptions escalate. This manufacturing trend gives companies greater control over their operations while improving customer service and reliability.

In addition, resilient supply chains also depend on asset reliability. If a factory cannot meet production commitments because of equipment downtime, even the best supply chain strategy fails. For this reason, manufacturers are increasingly linking supply chain planning with maintenance and asset management data. By aligning production, inventory, and maintenance schedules, companies can operate more predictably, even in volatile markets. In 2026, supply chain resilience is built on both smart logistics and reliable manufacturing assets.

Cybersecurity Becomes a Manufacturing Priority

As organizations become more connected and data-driven, cybersecurity has emerged as one of the fastest-growing trends in manufacturing. This translates into production systems, robots, sensors, and IIoT devices that are now part of the same digital ecosystem as ERP, CMMS, and cloud platforms. However, the convergence of IT and OT (operational technology) significantly increases the risk of cyber threats that can result in a production shutdown, compromise safety, or expose sensitive intellectual property.

To mitigate these risks, manufacturers are investing heavily in OT-focused cybersecurity strategies to protect machines, control systems, and plant networks. This includes network segmentation, real-time threat detection, access control, and continuous system monitoring. Modern cybersecurity platforms can detect anomalous machine behavior that may indicate a cyber intrusion, enabling companies to isolate affected systems before damage occurs. In 2026, cybersecurity will be just as essential to uptime as maintenance and reliability engineering.

Customer-Driven and Mass-Customized Manufacturing

One of the most transformative manufacturing trends of 2026 is the move from mass production to mass customization. Increasingly, customers expect products that reflect their specific needs, whether that means unique configurations, shorter lead times, or personalized features. Digital design tools, flexible automation, and advanced planning software are enabling the production of highly customized products at near-mass-production efficiency.

Digital twins, modular production lines, and AI-driven scheduling drive this shift. Manufacturers can simulate product designs, test production scenarios, and adjust workflows before any physical production begins. This reduces risk while enabling faster changeovers and smaller batch sizes. Instead of being locked into long production runs, factories can pivot quickly to meet shifting customer demand.

The result is improved competitiveness and profitability. By offering tailored products, manufacturers can command higher margins while strengthening customer loyalty. In 2026, customer-centric manufacturing will be one of the most powerful ways companies differentiate themselves in increasingly crowded global markets.

Regulatory and Compliance Technology Expands

Regulatory pressure is a growing source of stress and concern across industries, making automated compliance one of the most critical manufacturing trends of 2026. Manufacturing businesses are increasingly switching to digital compliance platforms because manual tracking and paper-based audits can no longer meet the demands of stricter regulations. These demands include heightened environmental regulations, more stringent safety standards, complex quality certifications, and evolving data governance requirements.

To overcome this major shortfall, modern CMMS, EHS, and quality management systems now automatically log inspections, maintenance activities, training records, and environmental data. This creates a continuous, verifiable audit trail that simplifies regulatory reporting and reduces the risk of fines, shutdowns, or legal exposure. Instead of scrambling to prepare for audits, manufacturers can demonstrate compliance in real time with just a few clicks.

Beyond risk reduction, compliance technology improves operational discipline and transparency. When inspections, maintenance, and safety checks are digitally enforced, organizations become more consistent and accountable, both internally and externally.

What These Manufacturing Trends Mean for Leaders in 2026

The above trends represent both a challenge and an opportunity for manufacturers. Running a successful operation in 2026 will require far more than managing machines and labor. Instead, it demands digital leadership, data literacy, and a long-term technology strategy. Organizational leaders must decide where to invest, how to modernize legacy systems, and how to align maintenance, production, and supply chain teams around shared data.

Conclusion

We reviewed the manufacturing trends shaping 2026 that support adaptability as the ultimate competitive advantage. From AI and automation to sustainability, cybersecurity, and predictive maintenance, every part of manufacturing is becoming more connected, intelligent, and data-driven. The result is maintenance activities that operate with greater efficiency, resilience, and insight than ever before.

Manufacturers who invest in modern platforms, empower their workforce, and use data to drive continuous improvement. With these tools, they will be best positioned to navigate uncertainty and capture new growth opportunities.

While the manufacturing trends shaping 2026 highlight significant advances in AI, automation, and connectivity, the most important takeaway is that technology adoption should align with business size, goals, and resources. Not every manufacturer needs smart factories, AI-driven maintenance, or complex data integrations to remain competitive.

TABLE OF CONTENTS

Keep Reading

Whether it’s football, baseball, hockey, or basketball, sporting events are big business. To ...

13 Feb 2026

The energy industry is facing numerous challenges on several fronts, including the transition ...

12 Feb 2026

School facilities are busy, high-traffic places. On average, 45.8 million students attend ...

10 Feb 2026

There is also no shortage of acronyms in the maintenance world. So, here is one more to add ...

6 Feb 2026

You may be wondering: if you are already using CMMS software in your organization, aren’t ...

5 Feb 2026

Although artificial intelligence (AI) has been around since the mid-1950s, it wasn’t until ...

3 Feb 2026

Fire safety is often treated as a compliance checkbox rather than an ongoing operational ...

30 Jan 2026

Schools are regarded as places of learning where children are exposed to the basics of ...

29 Jan 2026

Facility maintenance, much like running a business, defies one-size-fits-all solutions. The ...

27 Jan 2026

When we think of inspections, we usually think about ensuring regulatory compliance and ...

23 Jan 2026

In maintenance operations, having the right spare parts in the right amount and at the right ...

22 Jan 2026

The relentless march of technology continuously reshapes the industry landscape, and with it, ...

20 Jan 2026

New Year’s resolutions tend to focus on lifestyle or financial changes, often aimed at making ...

16 Jan 2026

Now that 2026 is here, it’s a great time to assess what can be achieved in maintenance ...

13 Jan 2026

2026 is when the role of a CMMS Software in capital allocation comes to the fore. This is the ...

12 Jan 2026

Choosing the right work order software is no longer optional for maintenance teams in 2026. ...

6 Jan 2026

By 2026, CMMS platforms will no longer be the limiting factor in maintenance performance. ...

30 Dec 2025

Spare parts management within maintenance can make the difference between a problem-free ...

16 Dec 2025

Every maintenance team eventually faces the same question: When should we repair, and when ...

12 Dec 2025

Enterprise Asset Management (EAM) software has become a cornerstone for organizations aiming ...

12 Dec 2025