Manage Overstocking Risks for Better Maintenance Management

In maintenance operations, having the right spare parts in the right amount and at the right time is critical. But having too many parts can be just as damaging as having too few. Overstocking quietly erodes budgets, clogs storerooms, and undermines maintenance efficiency, often without anyone realizing how much money and productivity are being lost. Overstocking can quickly escalate into a runaway train, where maintenance managers lose track of what they actually have.

When maintenance teams stockpile parts “just in case,” they create a false sense of security while increasing financial exposure. The goal of modern maintenance management isn’t maximum inventory. For maintenance managers, it’s making a smart inventory. In other words, it’s about finding that sweet spot between having too little and too much. Understanding and controlling overstocking risks is essential for improving uptime, cash flow, and operational agility.

This article explores the problems associated with overstocking parts and inventory and outlines the risks and how to avoid them.

What are Overstocking Risks?

Let’s start by defining overstock inventory. Overstocking generally occurs when a company holds more inventory than it realistically needs to support its maintenance operations. This often happens when spare parts, consumables, and materials are purchased in excess of actual demand, well in advance.

While safety stock is essential for critical assets, overstocking goes well beyond reasonable buffers. The result is often excess inventory that may never be used, become obsolete, or degrade before installation. In maintenance environments, where equipment changes and asset strategies evolve, excess stock quickly becomes a liability rather than an advantage. A liability of this nature translates into unnecessary costs.

What Causes Overstocking Risks in Maintenance?

Most overstocking problems begin with good intentions: a desire to avoid operational disruptions. Uncertainty is the primary driver of overstocking.

Inaccurate Demand Forecasting

Maintenance teams often overestimate the number of parts they will need. This occurs when work orders are not linked to inventory usage, and purchasing decisions are based on assumptions rather than real data. This mistake often leads to overbuying and slow-moving stock.

Bulk Purchasing and Vendor Incentives

We all like deals, and when ordering parts, maintenance managers, like many of us, are drawn to the best prices. Suppliers frequently offer discounts for large orders. Even as the price per unit declines, the total cost rises, increasing the risk that much of the inventory will remain unused.

“Just in Case” Stocking

Unreliable suppliers, long lead times, and the fear of downtime motivate maintenance managers to play it safe. The result is that they tend to hoard parts to maintain sufficient stock on hand, just in case. But this risk-avoidance overstocking strategy often creates greater financial and operational risks than stockouts.

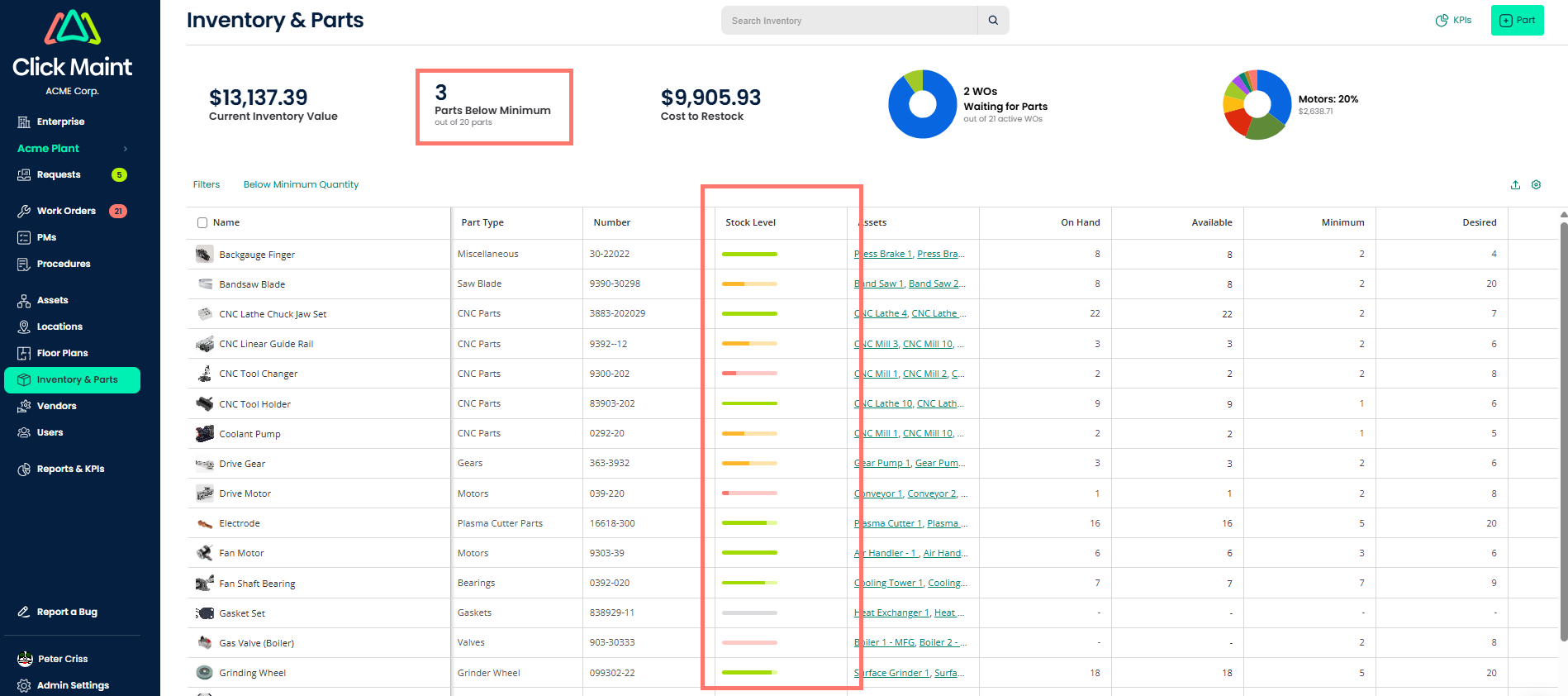

Poor Visibility into Inventory Stock Levels

When maintenance teams don’t know what is already in stock, duplicate orders can easily occur. Without a clear view of current stock levels, different departments may even order the same part without realizing it. Without real-time inventory visibility, organizations lose the ability to coordinate purchasing, leading to fragmented storerooms and higher carrying costs. It also makes it nearly impossible to identify slow-moving or obsolete items before they quietly impact budgets and occupy valuable space.

The Hidden Costs of Overstocking

We already made the point that in maintenance operations, having the right spare parts at the right time is critical. But having too many parts can be just as damaging as having too few, especially when it comes to budgets.

Capital Tied up in Inventory

Every unused part is money that could have been invested in preventive maintenance, staff training, or new technology. In other words, excess stock freezes cash flow. When large amounts of money are locked in excess stock, organizations lose the financial flexibility needed to respond to emerging operational risks. Overstocking weakens the maintenance budget and limits innovation.

Storage and Carrying Costs

Beyond the purchase price of inventory, every stocked item incurs ongoing expenses such as shelving, climate control, insurance, tracking, and labor. The more inventory you hold, the more you pay just to keep it. As inventory grows, these costs multiply, even if the parts are never used. Overstocking slowly and silently inflates overhead and makes maintenance operations more expensive than they need to be.

Obsolescence and Deterioration

Maintenance parts are especially vulnerable to becoming obsolete as equipment is upgraded or retired. In this regard, overstocking is money out the window. In addition to becoming obsolete, components can deteriorate. For example, seals dry out, electronics fail, and materials degrade while sitting on shelves. Degraded stock becomes unsafe, unreliable, or ineffective. This leads to wasted purchases and costly write-offs.

Operational Drag

An overcrowded storeroom makes it harder for technicians to quickly find what they need, slowing repairs and increasing downtime. Overstocking results in unnecessary time spent searching, counting, and managing excess inventory. All of this takes technicians’ focus away from reliability and preventive maintenance. The result is that overstocking creates inefficiency across the entire maintenance workflow.

Environmental Waste

It follows that excess inventory that expires, degrades, or becomes obsolete is often discarded. This wastes raw materials, energy, and transportation resources used to produce and deliver those parts. For organizations pursuing sustainability goals, overstocking directly undermines efforts directed toward environmental responsibility.

How Overstocking Hurts Maintenance Operations

The negative consequences of overstocking go beyond waste; it also directly impacts operational reliability and performance.

In manufacturing plants, warehouses filled with unused bearings, motors, and sensors complicate inventory oversight and slow down parts retrieval. In healthcare facilities, overstocked, expensive HVAC and electrical components often remain unused due to strained budgets. Utilities and power plants frequently store surplus turbine or transformer components that degrade long before they are ever needed.

In all cases, excess inventory adds complexity to maintenance operations, is more expensive, less efficient, and, ironically, makes departments less prepared.

How to Reduce Overstocking Risks

Smart maintenance organizations take a proactive approach to inventory control. Their decision-making is not based on uncertainty or on-the-fly concerns.

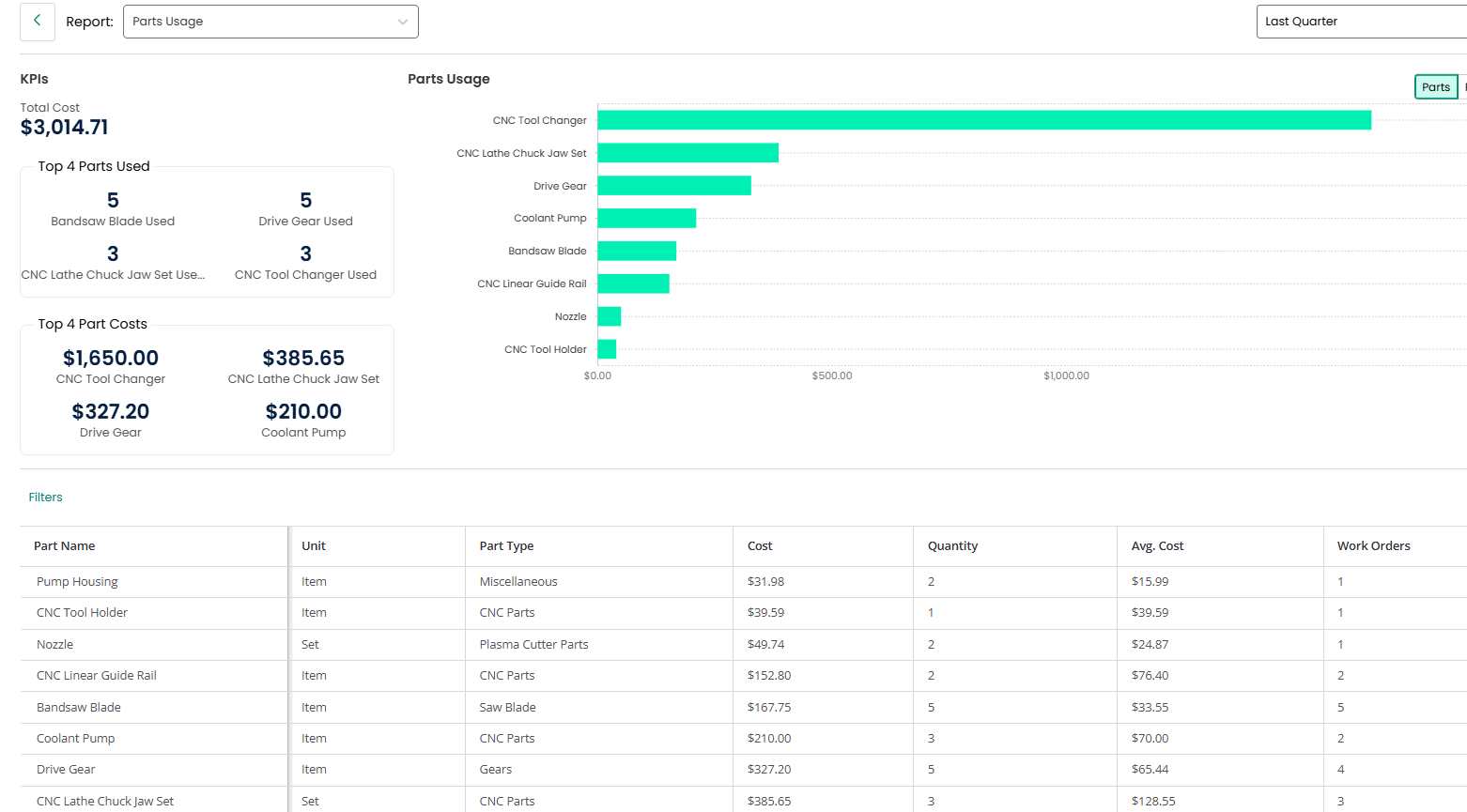

Use Data-Driven Demand Forecasting

Track how often parts are used through work orders. Let actual maintenance history and data, not gut feelings, inform purchasing decisions.

By analyzing parts use trends across preventive, corrective, and predictive maintenance, organizations can accurately predict future demand and avoid unnecessary stockpiling. This ensures inventory levels align with real asset behavior rather than worst-case assumptions.

Improve Inventory Visibility

Real-time stock tracking ensures maintenance teams see what inventory is already available. This prevents duplicate orders and reveals slow-moving items.

When technicians, planners, and procurement teams share the same inventory data, purchasing becomes coordinated instead of fragmented. Full visibility also makes it easier to spot overstocking risks before they grow into financial burdens.

Link Inventory to Maintenance Plans

When planned maintenance is linked to material requirements, parts are ordered as needed rather than months in advance.

This synchronization ensures inventory is consumed in alignment with maintenance schedules, reducing idle time for parts on shelves. It also improves work order accuracy by guaranteeing the right materials are available exactly when tasks are scheduled.

Prioritize Critical Spares

Not all parts require the same stocking strategy. Instead, focus inventory investment on assets that would cause significant downtime if they failed.

By ranking parts based on asset criticality and failure impact, organizations can avoid wasting capital on low-risk items. A targeted approach like this ensures high-value components are always available without overstocking other items.

Audit Slow-Moving and Obsolete Stock

Review inventory regularly and remove items that haven’t been used in years. Selling or scrapping dead stock is often cheaper than storing it.

Routine inventory audits, combined with cycle counts, help identify excess parts that no longer support current equipment or maintenance strategies. Eliminating dead stock frees up storage space and recovers some value that can be reinvested in more productive maintenance activities.

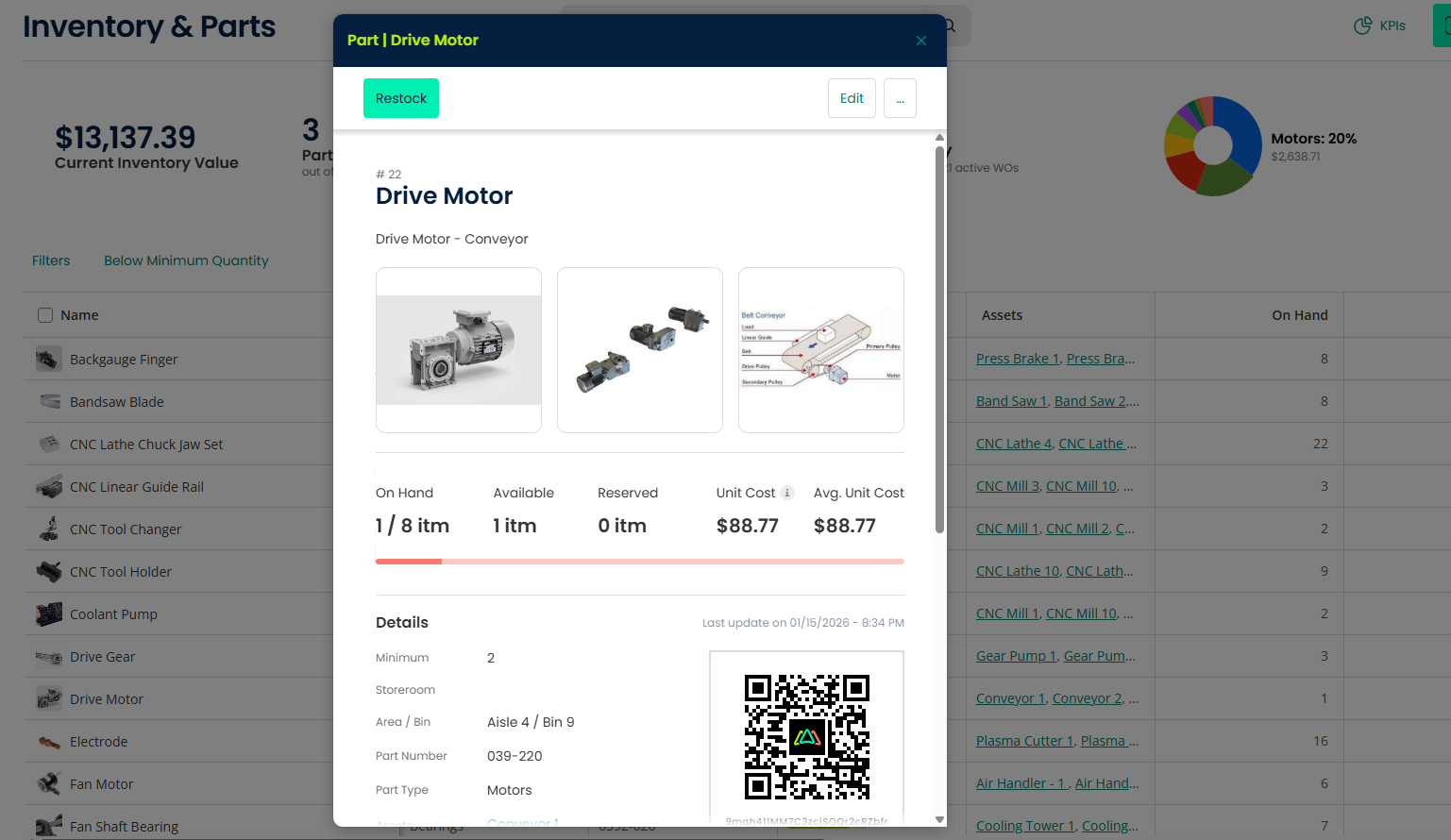

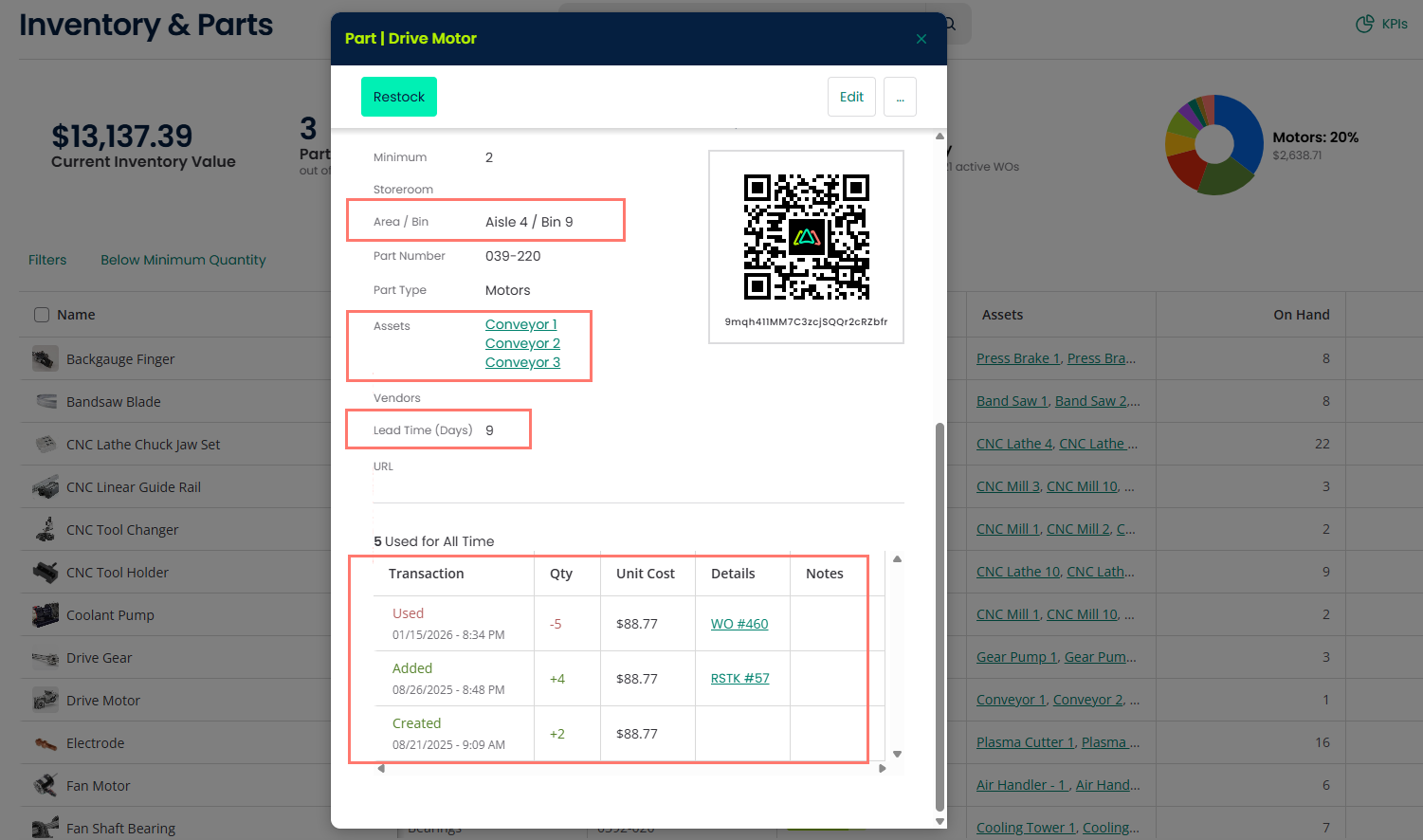

How CMMS Software Reduces Overstocking Risks

A modern CMMS is one of the most powerful tools for mitigating the risks of overstocking. It allows maintenance teams to move from reactive purchasing to data-driven inventory planning. The software eliminates guesswork, hunches, and worries. More specifically, by centralizing asset data, parts usage, and maintenance schedules in a single system, CMMS platforms eliminate blind spots that lead to overbuying. They also create accountability by showing exactly when, why, and how inventory is being consumed, turning inventory control into a strategic advantage rather than a guessing game.

A CMMS allows maintenance teams to:

- Track real-time inventory levels

- Tie parts usage directly to work orders

- Predict future demand based on historical trends

- Set reorder points based on actual consumption

- Identify slow-moving and obsolete items

- Create accountability for purchasing decisions

By connecting inventory to assets, schedules, and maintenance strategies, CMMS software transforms inventory from guesswork into a strategic resource.

The Benefits of Controlling Overstocking Risks

When overstocking risks are appropriately managed, organizations see immediate and long-term improvements such as:

- More working capital for maintenance and upgrades

- Lower warehousing and handling costs

- Faster response times to equipment failures

- Less waste and better sustainability performance

- More predictable, stable maintenance budgets

The result is that, instead of organizations drowning in excess parts, maintenance teams gain clarity, control, and confidence.

What These Manufacturing Trends Mean for Leaders in 2026

The above trends represent both a challenge and an opportunity for manufacturers. Running a successful operation in 2026 will require far more than managing machines and labor. Instead, it demands digital leadership, data literacy, and a long-term technology strategy. Organizational leaders must decide where to invest, how to modernize legacy systems, and how to align maintenance, production, and supply chain teams around shared data.

Conclusion

We reviewed the manufacturing trends shaping 2026 that support adaptability as the ultimate competitive advantage. From AI and automation to sustainability, cybersecurity, and predictive maintenance, every part of manufacturing is becoming more connected, intelligent, and data-driven. The result is maintenance activities that operate with greater efficiency, resilience, and insight than ever before.

Manufacturers who invest in modern platforms, empower their workforce, and use data to drive continuous improvement. With these tools, they will be best positioned to navigate uncertainty and capture new growth opportunities.

While the manufacturing trends shaping 2026 highlight significant advances in AI, automation, and connectivity, the most important takeaway is that technology adoption should align with business size, goals, and resources. Not every manufacturer needs smart factories, AI-driven maintenance, or complex data integrations to remain competitive.

TABLE OF CONTENTS

Keep Reading

The relentless march of technology continuously reshapes the industry landscape, and with it, ...

20 Jan 2026

New Year’s resolutions tend to focus on lifestyle or financial changes, often aimed at making ...

16 Jan 2026

Now that 2026 has arrived, we’ll see that manufacturing trends will matter more than ever, as ...

15 Jan 2026

Now that 2026 is here, it’s a great time to assess what can be achieved in maintenance ...

13 Jan 2026

2026 is when the role of a CMMS Software in capital allocation comes to the fore. This is the ...

12 Jan 2026

Choosing the right work order software is no longer optional for maintenance teams in 2026. ...

6 Jan 2026

By 2026, CMMS platforms will no longer be the limiting factor in maintenance performance. ...

30 Dec 2025

Spare parts management within maintenance can make the difference between a problem-free ...

16 Dec 2025

Every maintenance team eventually faces the same question: When should we repair, and when ...

12 Dec 2025

Enterprise Asset Management (EAM) software has become a cornerstone for organizations aiming ...

12 Dec 2025

Unexpected equipment breakdowns can disrupt operations, increase repair costs, and reduce ...

11 Dec 2025

Businesses are always looking for ways to improve efficiencies, reduce costs, and improve ...

9 Dec 2025

The longest U.S. federal government shutdown to date lasted 43 days, beginning on October 1, ...

5 Dec 2025

Every maintenance professional faces it sooner or later — that critical time when an aging ...

18 Nov 2025

The term 'best' is often used loosely, without a clear understanding of its context or ...

14 Nov 2025

In the not too distant past, maintenance strategies have been defined by reaction—fixing ...

13 Nov 2025

Tax season is the time of year that often sends a ripple of anxiety through many of us. The ...

11 Nov 2025

Selecting a Computerized Maintenance Management System (CMMS) can, at first glance, be an ...

4 Nov 2025

In healthcare facilities, equipment uptime involves more than achieving operational ...

31 Oct 2025

Companies are subject to economic ups and downs, also known as economic volatility. Today, ...

30 Oct 2025