Streamline Facility Fire Safety Inspections, Testing, and Maintenance

Fire safety is often treated as a compliance checkbox rather than an ongoing operational priority; the reality is quite different. According to the National Fire Protection Association (NFPA)’s statistics, this runs counter to a commonly held belief that facilities are generally safe from fire hazards. It becomes abundantly clear that fire safety maintenance is and should be one of the most critical responsibilities within any facility. In other words, inspections, testing, and maintenance of fire protection systems should not be mere regulatory requirements. Instead, they should be considered essential safeguards that protect lives, property, and business continuity, rather than disorganized or reactive activities that also contribute to failed inspections, costly emergency repairs, and unnecessary operations downtime.

The bottom line is that streamlining fire safety maintenance means creating consistent, repeatable processes that ensure systems are always ready to perform as intended. With proper planning, documentation, and technology use, organizations can reduce administrative burden, increase confidence in compliance, and ensure fire protection systems remain reliable year-round. Let’s explore this topic more fully.

What Does Fire Safety Maintenance Involve?

When we talk about fire safety maintenance, we’re referring to a comprehensive network of systems and assets designed to prevent fires, detect them quickly when they occur, and respond effectively to limit their impact. These systems typically include fire alarm and detection systems that provide early warning, sprinkler and suppression systems that control or extinguish flames, and portable fire extinguishers that allow for immediate, localized response.

Beyond these core systems, supporting systems such as emergency lighting and exit signage ensure safe evacuation during power loss or reduced visibility, while fire doors and smoke control equipment help contain fire and smoke, slowing their spread and protecting escape routes. Each of these components plays a distinct yet interconnected role, and maintaining them together is essential to safeguarding occupants, reducing property damage, and enabling emergency responders to act quickly and safely.

The application of these systems in specific environments will be explored below.

Fire Safety Maintenance for Schools and Educational Facilities

Fire safety maintenance in schools involves utilizing a coordinated set of systems designed to protect large, often vulnerable populations during daily operations and emergencies. These systems include fire alarm and detection systems that provide early warning throughout classrooms and common areas, sprinkler and suppression systems that help control fires before they spread, and fire extinguishers positioned for staff response. Emergency lighting and exit signage are critical for guiding students and staff safely during evacuations, while fire doors and smoke control systems help contain hazards and protect evacuation routes. Because schools operate on predictable schedules and must meet strict regulatory standards, consistent fire safety maintenance is essential to minimizing risk, maintaining compliance, and ensuring a safe learning environment.

Fire Safety Maintenance for Healthcare Facilities

In healthcare environments, fire safety maintenance supports life safety in settings where evacuation may be complex or delayed. Fire alarm and detection systems must provide immediate, reliable alerts without disrupting critical care. In contrast, sprinkler and suppression systems play a key role in controlling fires in patient areas and mechanical spaces. Fire extinguishers enable trained staff to respond quickly to small incidents, and emergency lighting and exit signage ensure visibility during power interruptions. Fire doors and smoke control equipment are especially vital in healthcare facilities, as they help compartmentalize fire and smoke, protecting patients who cannot be easily moved. Maintaining these systems through rigorous fire safety maintenance is essential to patient safety, regulatory compliance, and uninterrupted care delivery.

Fire Safety Maintenance for Manufacturing and Industrial Facilities

Fire safety maintenance in manufacturing and industrial facilities focuses on managing the higher fire risks posed by machinery, electrical systems, and combustible materials. Fire alarm and detection systems provide early alerts in large or noisy environments, while sprinkler and specialized suppression systems are designed to control fires near production equipment and storage areas. Fire extinguishers allow trained personnel to respond quickly to localized incidents before they escalate. Emergency lighting, exit signage, fire doors, and smoke control systems support safe evacuation and help protect critical production zones. Because downtime and safety incidents can have significant operational and financial consequences, consistent fire safety maintenance is a key component of risk management and business continuity.

As we’ve just learned, effective fire safety maintenance goes beyond checking boxes. It requires regular inspections to confirm physical condition and accessibility, testing to verify proper operation, and maintenance to repair or replace components that no longer meet performance standards. When these activities are properly coordinated and documented, facilities gain greater visibility into system health and reduce the likelihood of failures during emergencies.

Understanding Inspection, Testing, and Maintenance (ITM) Requirements

A common challenge in fire safety maintenance is misunderstanding the distinction between inspection, testing, and maintenance. More precisely, inspections are primarily visual checks to ensure equipment is present, accessible, and free from obvious damage. Testing involves functional verification, such as activating alarms, checking water flow in sprinkler systems, or confirming emergency lighting operation. Maintenance refers to corrective actions taken when issues are identified, including repairs, replacements, or system adjustments.

Regulatory bodies and standards, such as NFPA, define specific ITM frequencies and procedures for different fire protection systems. Failure to meet these requirements can result in violations, fines, or increased liability. Understanding ITM expectations allows maintenance teams to plan work proactively rather than scrambling to meet inspection deadlines or address last-minute deficiencies.

Plan and Schedule Routine Fire Safety Maintenance

Consistent scheduling is central to effective fire safety maintenance. When inspections and testing are performed on an ad hoc basis, tasks are easily missed, records become incomplete, and compliance risks increase. A structured maintenance plan ensures that required activities are performed at appropriate intervals (monthly, quarterly, semi-annually, or annually) depending on the system type and regulatory requirements.

Proactive scheduling also helps facilities allocate labor and budget more effectively. High-risk areas, such as high-occupancy spaces, critical infrastructure rooms, or hazardous-material storage areas, can be prioritized accordingly. By embedding fire safety maintenance into routine workflows, organizations reduce surprises and ensure systems remain inspection-ready at all times.

Use Technology to Streamline Fire Safety Maintenance

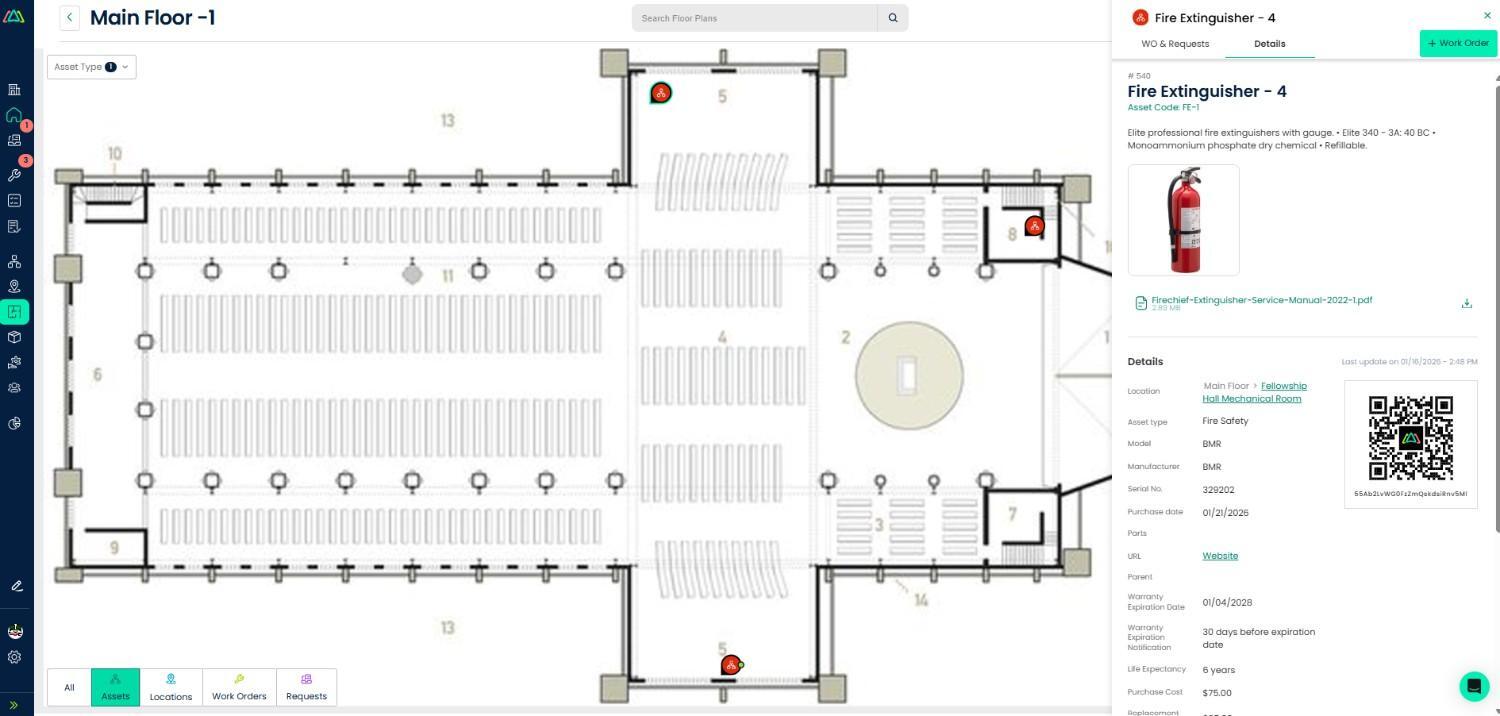

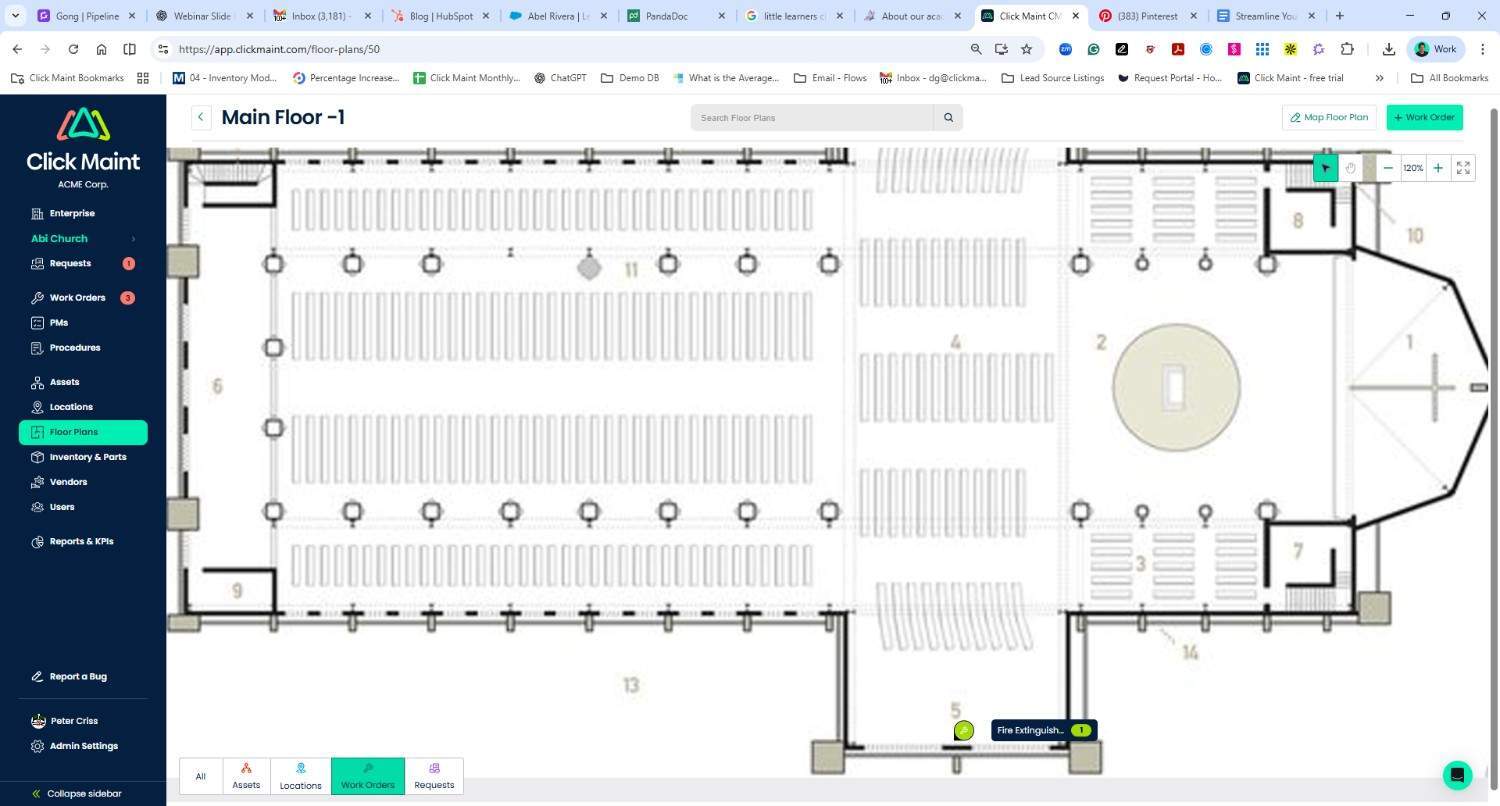

Technology plays a critical role in simplifying and standardizing fire safety maintenance programs. A computerized maintenance management system (CMMS) allows teams to automate recurring inspections, generate work orders, and maintain centralized digital records. This reduces reliance on paper logs, manual reminders, and institutional knowledge that can be lost over time.

CMMS platforms also improve accountability and visibility. Maintenance teams can track task completion, attach inspection reports and photos, and quickly retrieve records during audits or fire marshal visits. When integrated with building systems or inspection management tools, technology enables faster response to issues and supports a more proactive, data-driven approach to fire safety maintenance.

Best Practices for Conducting Fire Safety Maintenance

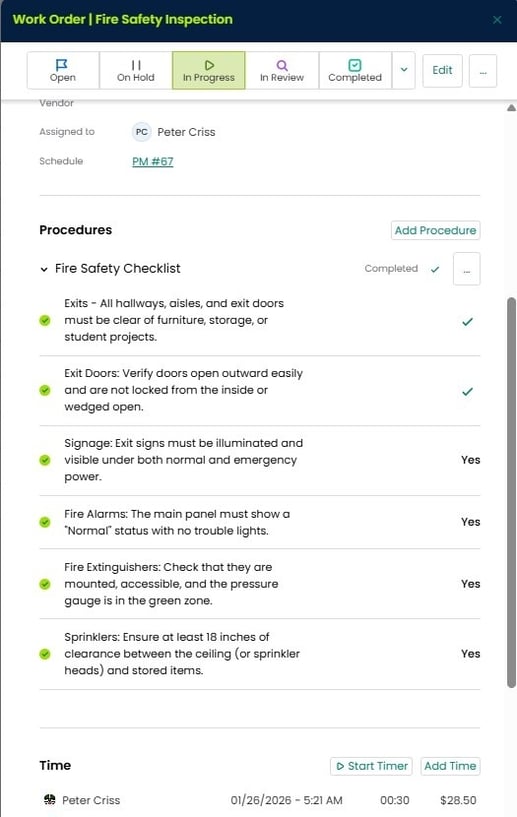

Consistency is key to effective fire safety maintenance. This means that maintenance managers possess standardized inspection checklists that ensure all required components are reviewed during each inspection and that no critical steps are overlooked. These checklists should align with applicable codes and manufacturer recommendations to maintain compliance and system reliability.

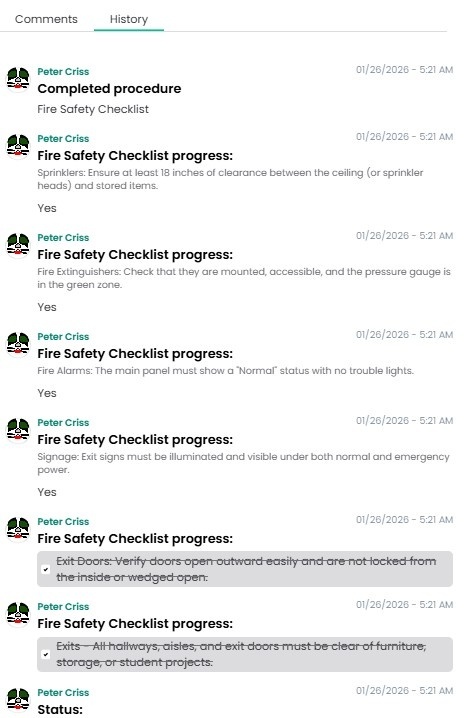

Thorough documentation is equally important. Detailed records of inspections, test results, corrective actions, and system changes provide a defensible audit trail and demonstrate due diligence. In addition, ongoing training ensures maintenance staff understand system requirements, while partnerships with certified fire protection professionals help address specialized testing or repairs that require licensed expertise.

Prepare for Audits and Regulatory Inspections

Regulatory inspections can be far less stressful when fire safety maintenance records are organized and readily accessible. Fire marshals and inspectors typically require proof of completed inspections, testing logs, and evidence that deficiencies were corrected promptly. Incomplete or inconsistent documentation often leads to repeat inspections or citations.

A well-managed fire safety maintenance program allows facilities to respond with confidence and accuracy during audits. Digital records, time-stamped work orders, and inspection histories demonstrate compliance and professionalism. Preparing for audits should become a routine exercise rather than a disruptive event when documentation is continuously maintained.

Common Challenges and Practical Solutions

Many organizations struggle to keep up with fire safety maintenance due to competing priorities, limited staffing, or fragmented processes. Missed inspection frequencies are common when tasks rely on manual tracking or informal reminders. Automated scheduling and notifications within a CMMS help eliminate these gaps and ensure no tasks fall through the cracks.

Incomplete documentation is another frequent issue facing maintenance teams. Digital tools that allow mobile data entry, photo uploads, and standardized forms significantly improve record accuracy. For organizations facing resource constraints, prioritizing preventive maintenance and selectively outsourcing specialized tasks can help maintain compliance without overburdening internal teams. Now, let’s explore several advanced strategies for fire safety maintenance.

Advanced Strategies for High-Performance Fire Safety Programs

Organizations seeking to elevate their fire safety maintenance programs can adopt risk-based strategies that focus attention on areas where failure would have the most severe consequences. Rather than applying the same inspection frequency and level of oversight to every asset, maintenance teams can align effort with risk by considering occupancy levels, asset criticality, and potential impact on life safety and operations.

For example, in a healthcare facility, fire alarm panels, smoke dampers, and sprinkler systems serving patient care areas and surgical suites may require more frequent inspections than those in administrative offices. A malfunction in these areas could delay evacuation or compromise patient safety, making enhanced oversight essential. Risk-based fire safety maintenance ensures that life-critical systems receive priority attention without overextending resources elsewhere.

In schools and universities, high-occupancy spaces such as auditoriums, gymnasiums, cafeterias, and dormitories often warrant increased inspection frequency for alarms, exit signage, and emergency lighting. During events or peak occupancy periods, these areas pose greater evacuation challenges, and targeted maintenance helps ensure systems function properly when needed most.

In manufacturing and industrial environments, assets protecting production lines, electrical rooms, and hazardous-material storage areas often pose a higher fire risk. Fire suppression systems, detection sensors, and fire doors in these zones may be reviewed more frequently due to the potential for rapid fire spread, equipment damage, or extended downtime. This approach allows maintenance teams to reduce business interruption risk while maintaining compliance.

When supported by a CMMS, risk-based fire safety maintenance becomes easier to manage. Assets can be assigned risk ratings, inspection frequencies adjusted accordingly, and work orders automatically prioritized. This ensures that limited labor and budgets are directed where they deliver the greatest safety impact, strengthening compliance while optimizing resource use.

Conclusion

Fire safety maintenance doesn’t have to be complex or reactive, but it must be an integrated, essential part of an organization’s overall maintenance operations. When inspections, testing, and essential maintenance are carefully planned, thoroughly documented, and supported by the right technology, facility, and maintenance managers gain greater control over compliance with stringent regulations and significantly enhance their risk management posture. Streamlined, technology-supported processes dramatically reduce the administrative burden on facility teams while simultaneously improving fire system reliability, ultimately leading to superior safety outcomes. This proactive approach ensures that crucial fire safety equipment remains fully functional.

By treating fire safety maintenance as an ongoing operational discipline rather than a periodic obligation, organizations protect their most valuable assets: their people, their physical property and infrastructure, and their reputation. A proactive, well-structured approach, supported by automated scheduling and digital record-keeping, ensures that when genuine emergencies do occur, or when official regulatory inspections are pending, your facility is not only prepared but can demonstrate a robust, auditable history of compliance and system readiness.

TABLE OF CONTENTS

Keep Reading

Schools are regarded as places of learning where children are exposed to the basics of ...

29 Jan 2026

Facility maintenance, much like running a business, defies one-size-fits-all solutions. The ...

27 Jan 2026

When we think of inspections, we usually think about ensuring regulatory compliance and ...

23 Jan 2026

In maintenance operations, having the right spare parts in the right amount and at the right ...

22 Jan 2026

The relentless march of technology continuously reshapes the industry landscape, and with it, ...

20 Jan 2026

New Year’s resolutions tend to focus on lifestyle or financial changes, often aimed at making ...

16 Jan 2026

Now that 2026 has arrived, we’ll see that manufacturing trends will matter more than ever, as ...

15 Jan 2026

Now that 2026 is here, it’s a great time to assess what can be achieved in maintenance ...

13 Jan 2026

2026 is when the role of a CMMS Software in capital allocation comes to the fore. This is the ...

12 Jan 2026

Choosing the right work order software is no longer optional for maintenance teams in 2026. ...

6 Jan 2026

By 2026, CMMS platforms will no longer be the limiting factor in maintenance performance. ...

30 Dec 2025

Spare parts management within maintenance can make the difference between a problem-free ...

16 Dec 2025

Every maintenance team eventually faces the same question: When should we repair, and when ...

12 Dec 2025

Enterprise Asset Management (EAM) software has become a cornerstone for organizations aiming ...

12 Dec 2025

Unexpected equipment breakdowns can disrupt operations, increase repair costs, and reduce ...

11 Dec 2025

Businesses are always looking for ways to improve efficiencies, reduce costs, and improve ...

9 Dec 2025

The longest U.S. federal government shutdown to date lasted 43 days, beginning on October 1, ...

5 Dec 2025

Every maintenance professional faces it sooner or later — that critical time when an aging ...

18 Nov 2025

The term 'best' is often used loosely, without a clear understanding of its context or ...

14 Nov 2025

In the not too distant past, maintenance strategies have been defined by reaction—fixing ...

13 Nov 2025